Research on Low Leakage Current Voltage Sampling Method for Multi-cell Series Battery Packs

-

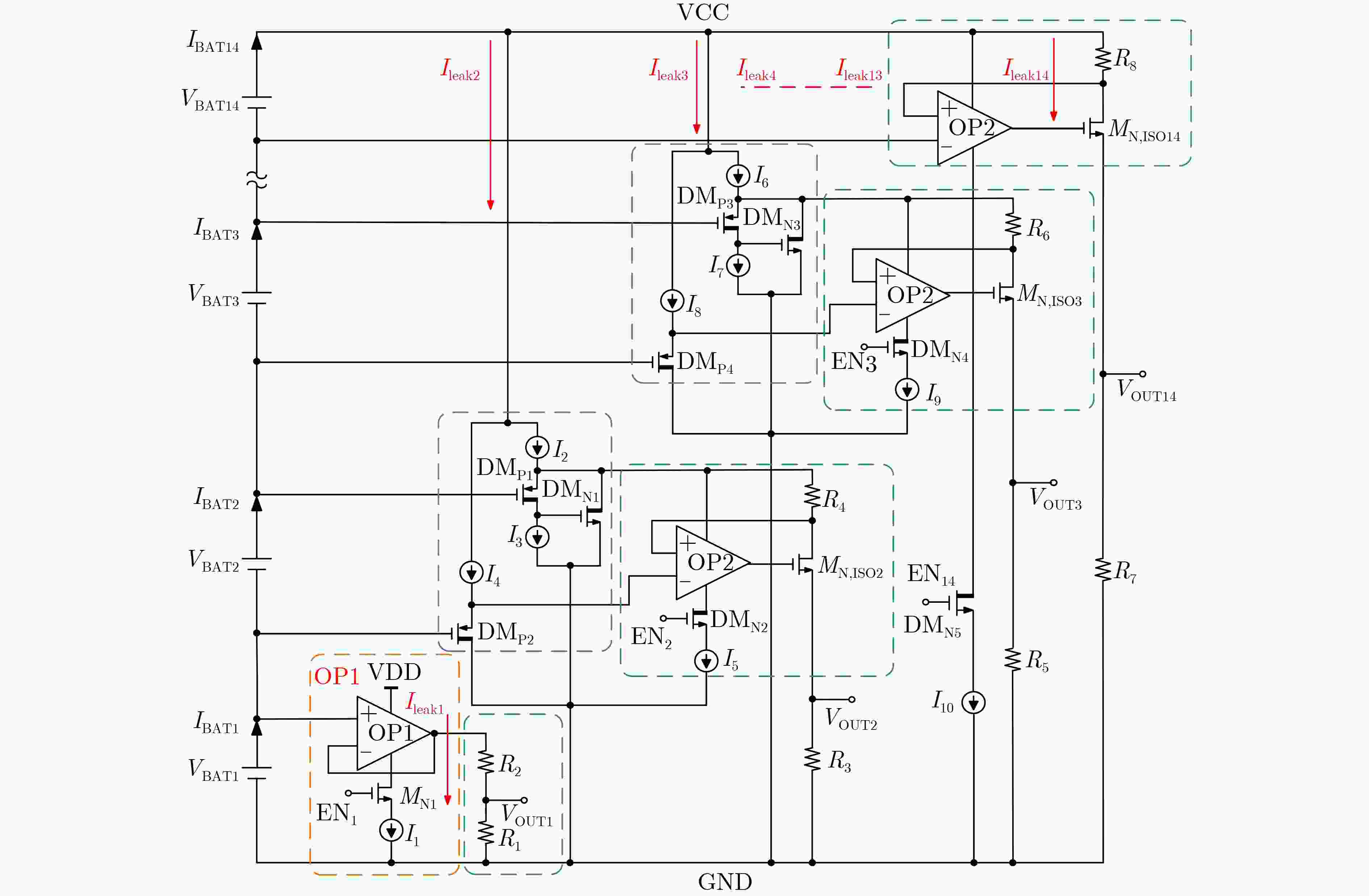

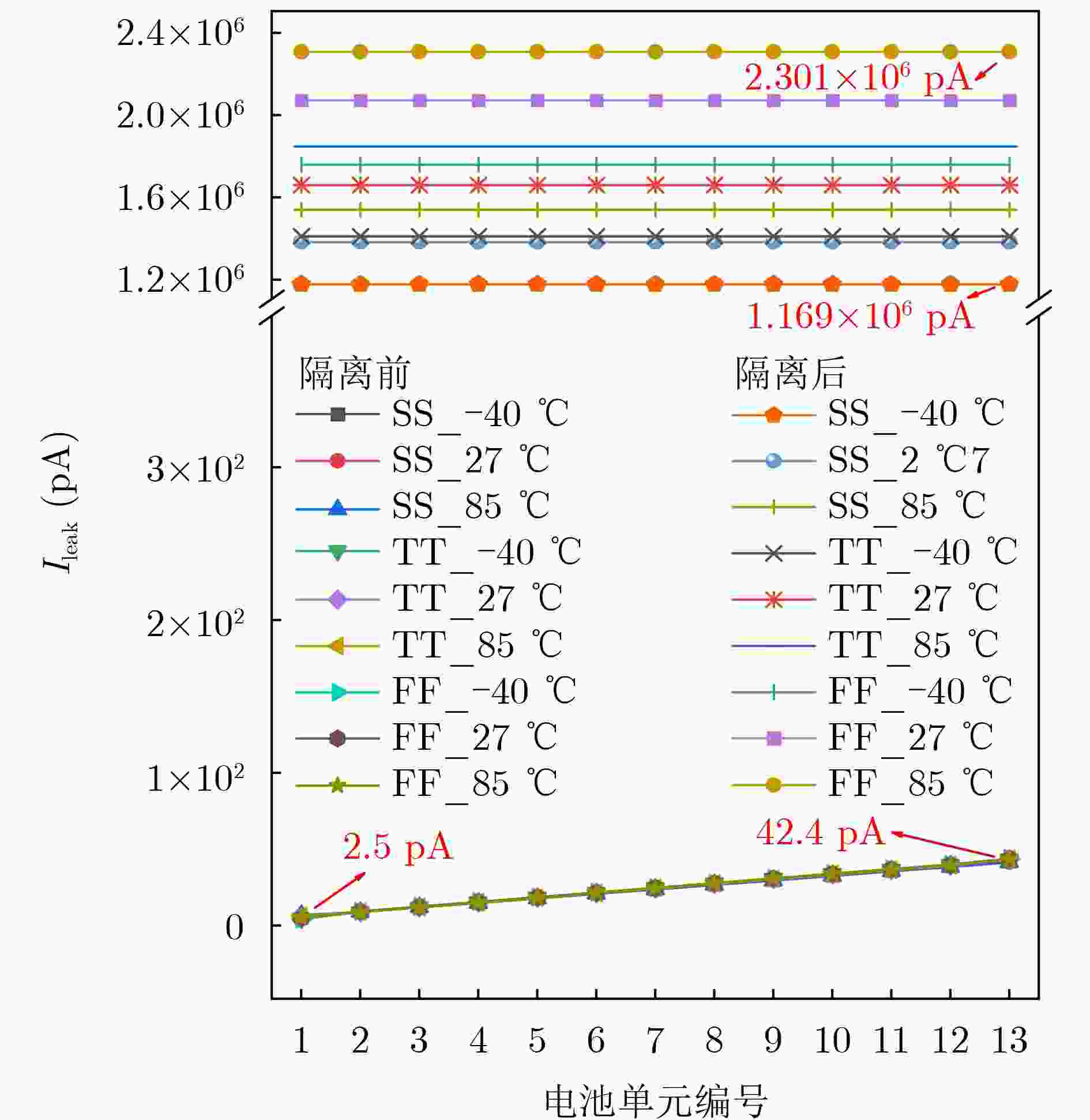

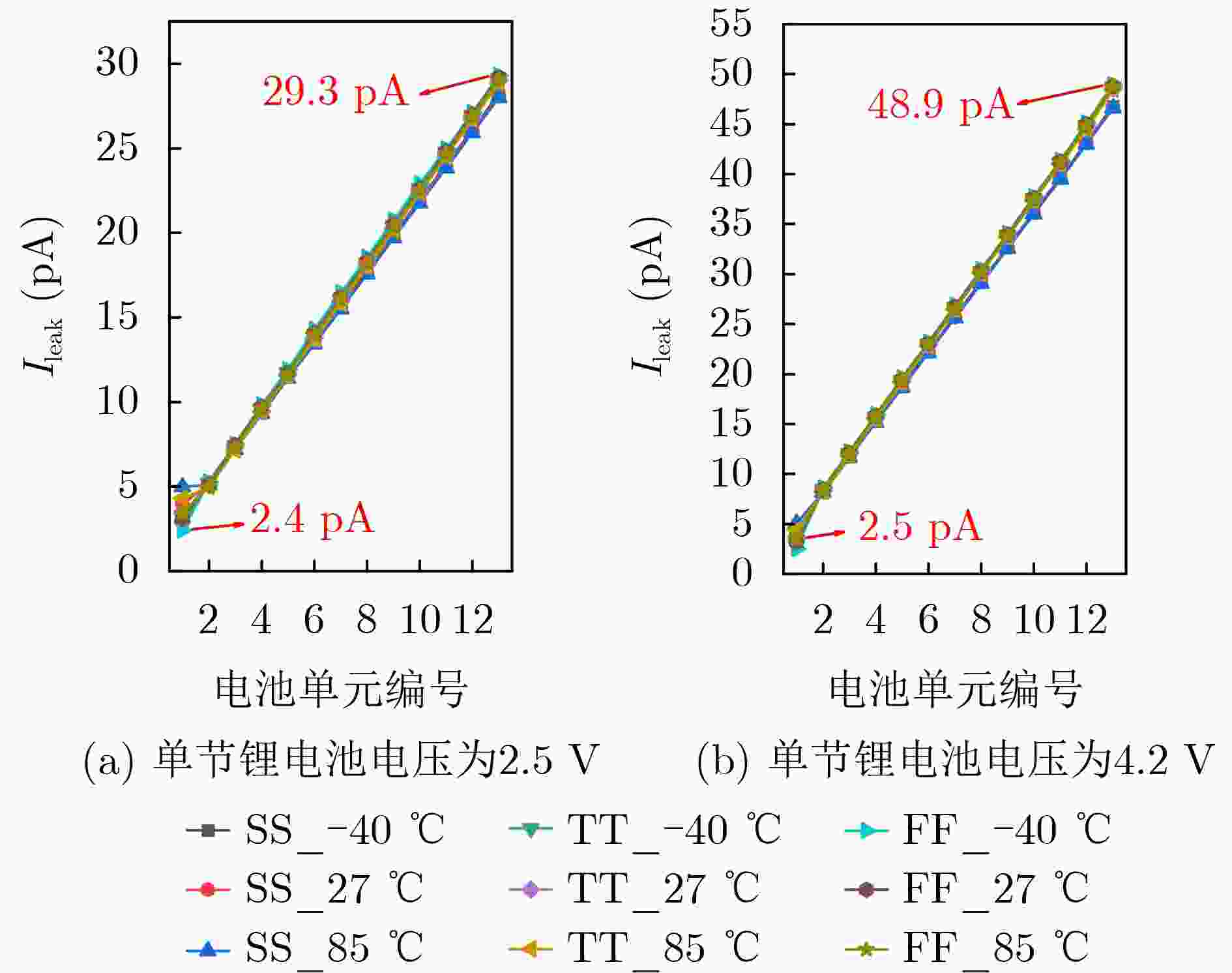

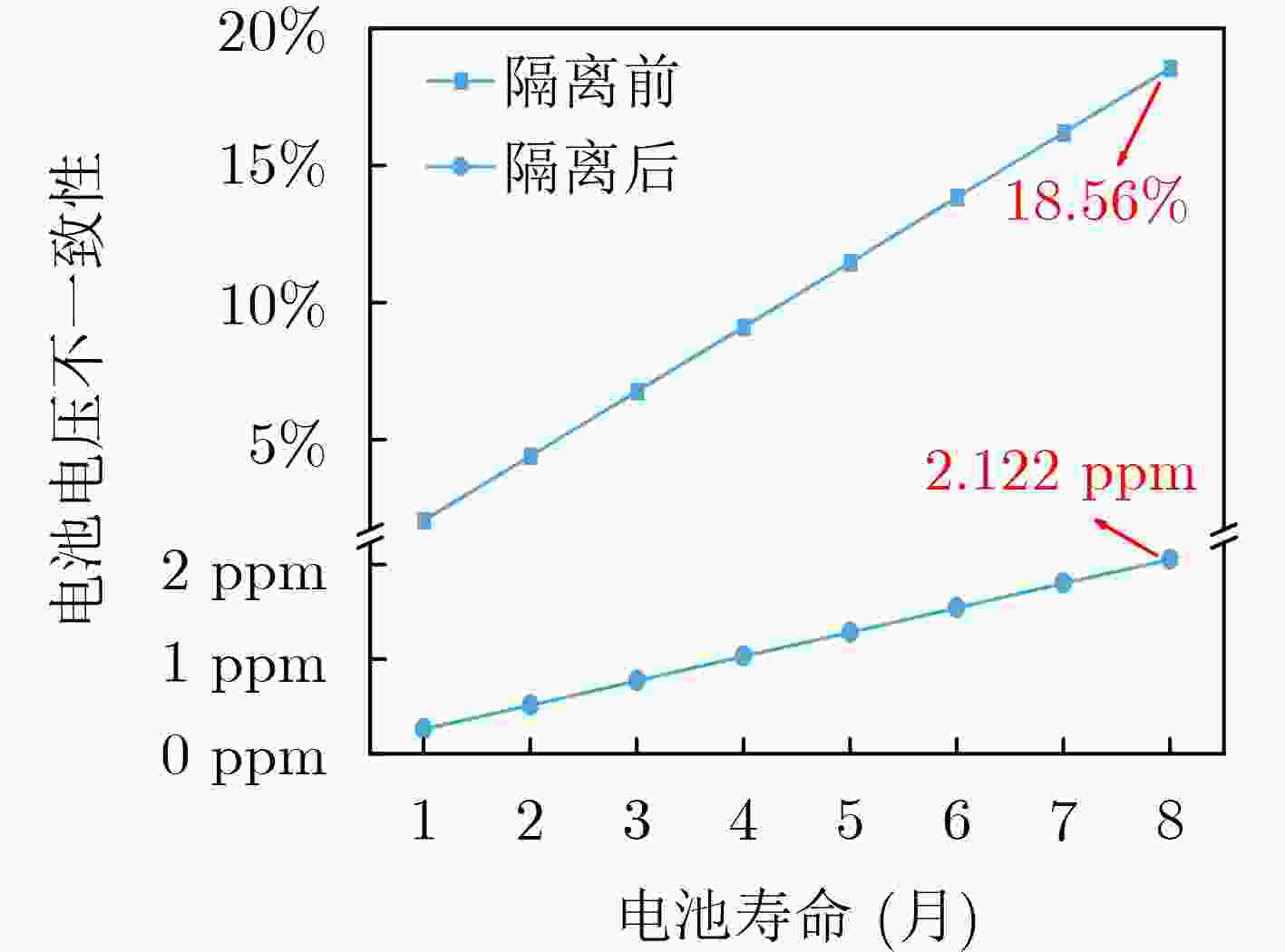

摘要: 针对多节串联电池组采样电路存在通道漏电流导致各节电池电压不一致和影响采样精度的问题,本文提出了一种应用于14节串联锂电池的低漏电流电池电压采样方法。通过分析漏电流的产生机制,采用运放隔离有源驱动技术,减小各节电池的通道漏电流,同时为了减小高压MOSFET带来的面积开销,改进了高压域运算放大器。基于0.35 μm高压BCD(Bipolar CMOS DMOS)工艺对电路进行了详细设计和完整性能验证,结果表明,所设计的电池电压采样电路版图面积仅为3.105×0.638 mm2,在不同的温度和工艺角组合下,最大通道漏电流低至48.9 pA。在全面的PVT(Process Voltage Temperature)验证下,电池电压采样最大测量误差小于1.25 mV。该方法将采样过程对电池电压不一致性的影响从18.56%降低至2.122 ppm,为高可靠高精度多节串联电池管理系统提供了有效的解决方案。Abstract:

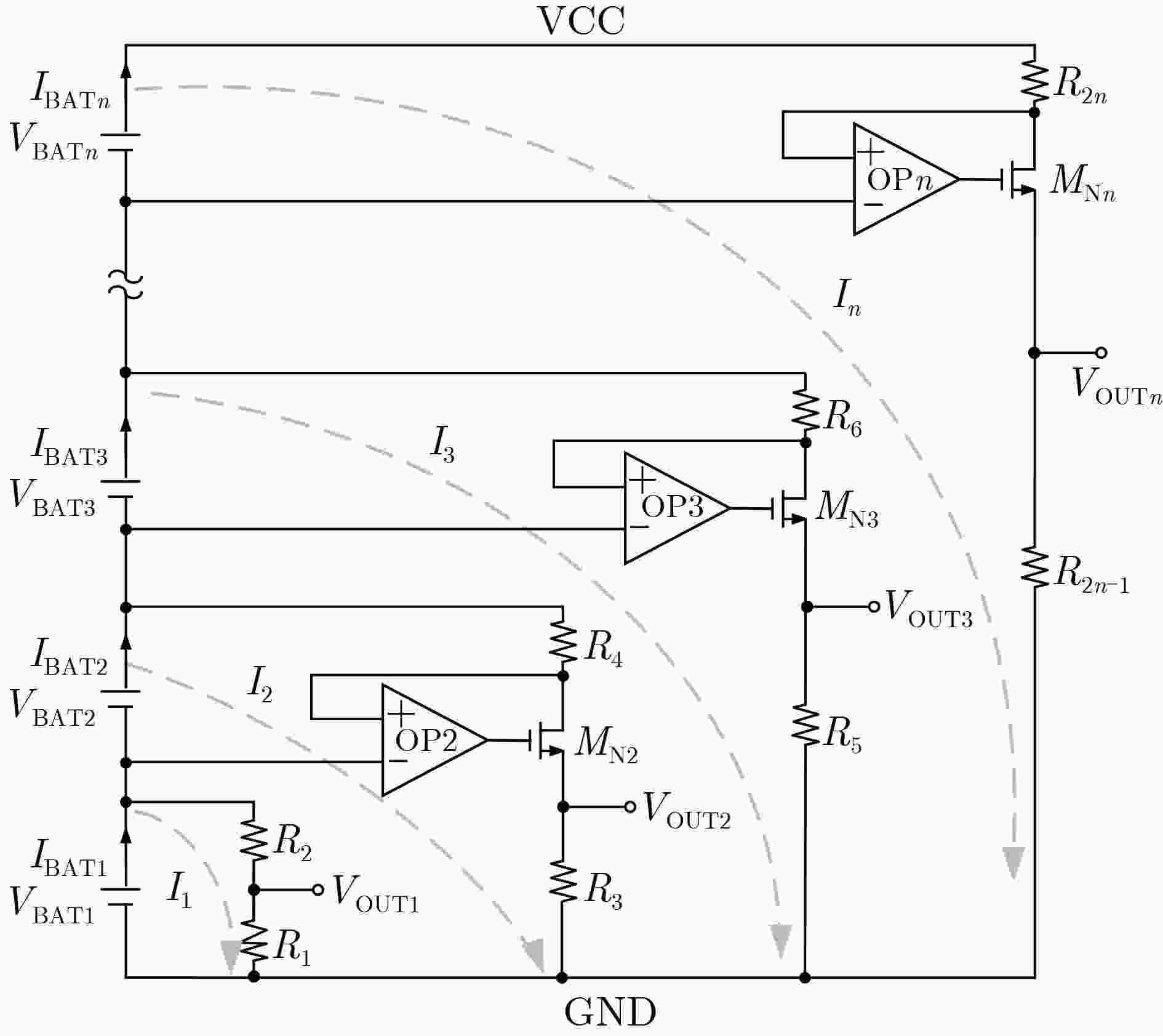

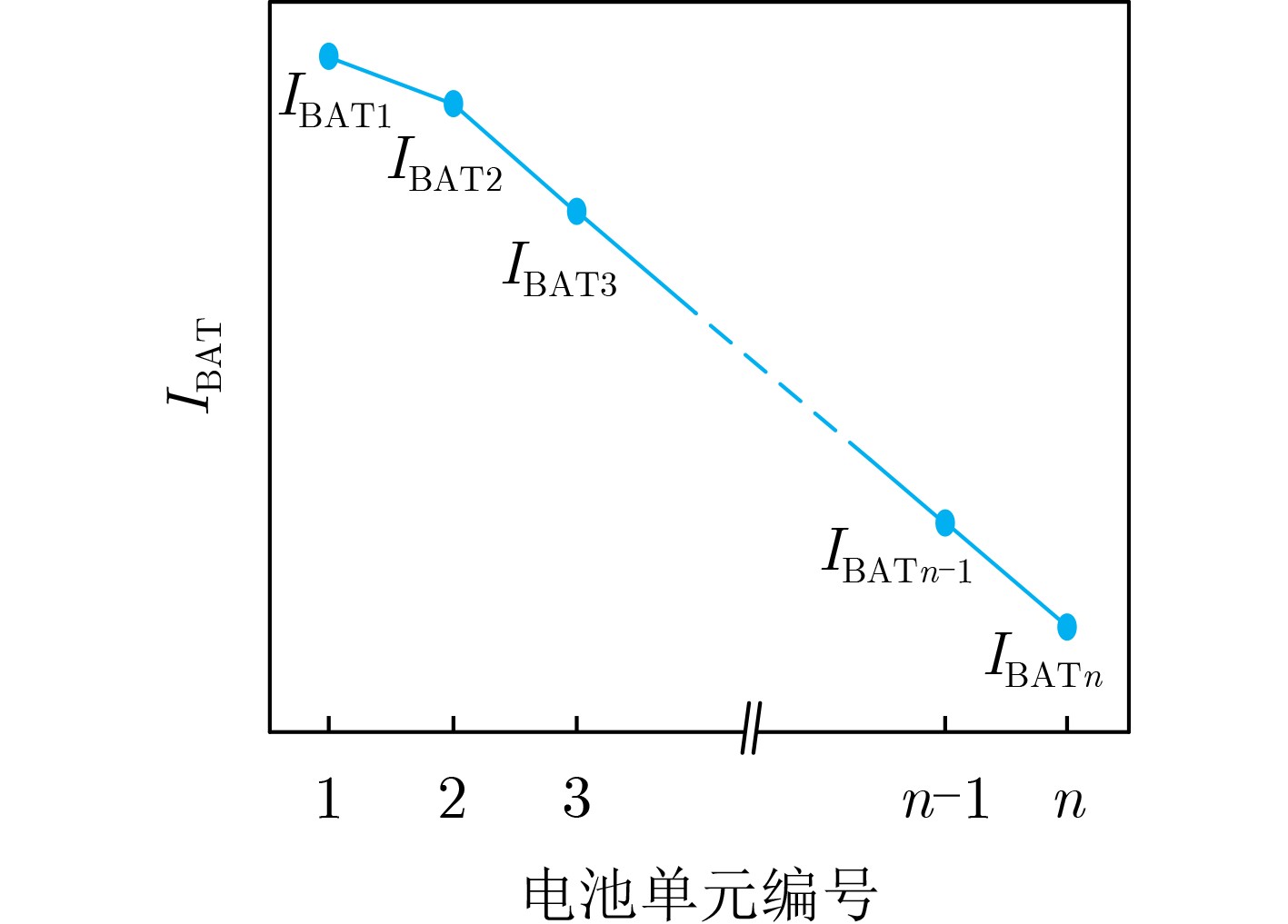

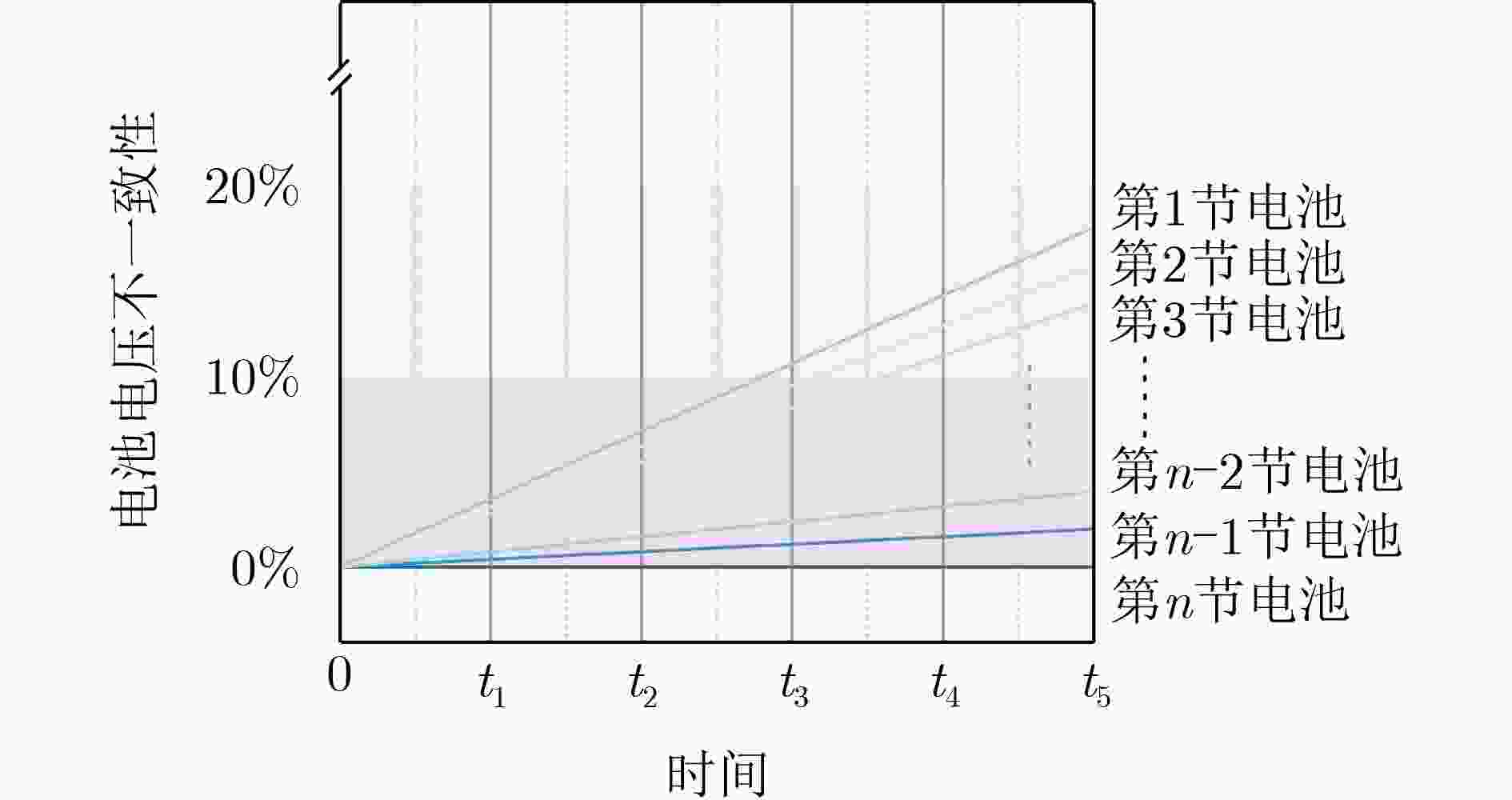

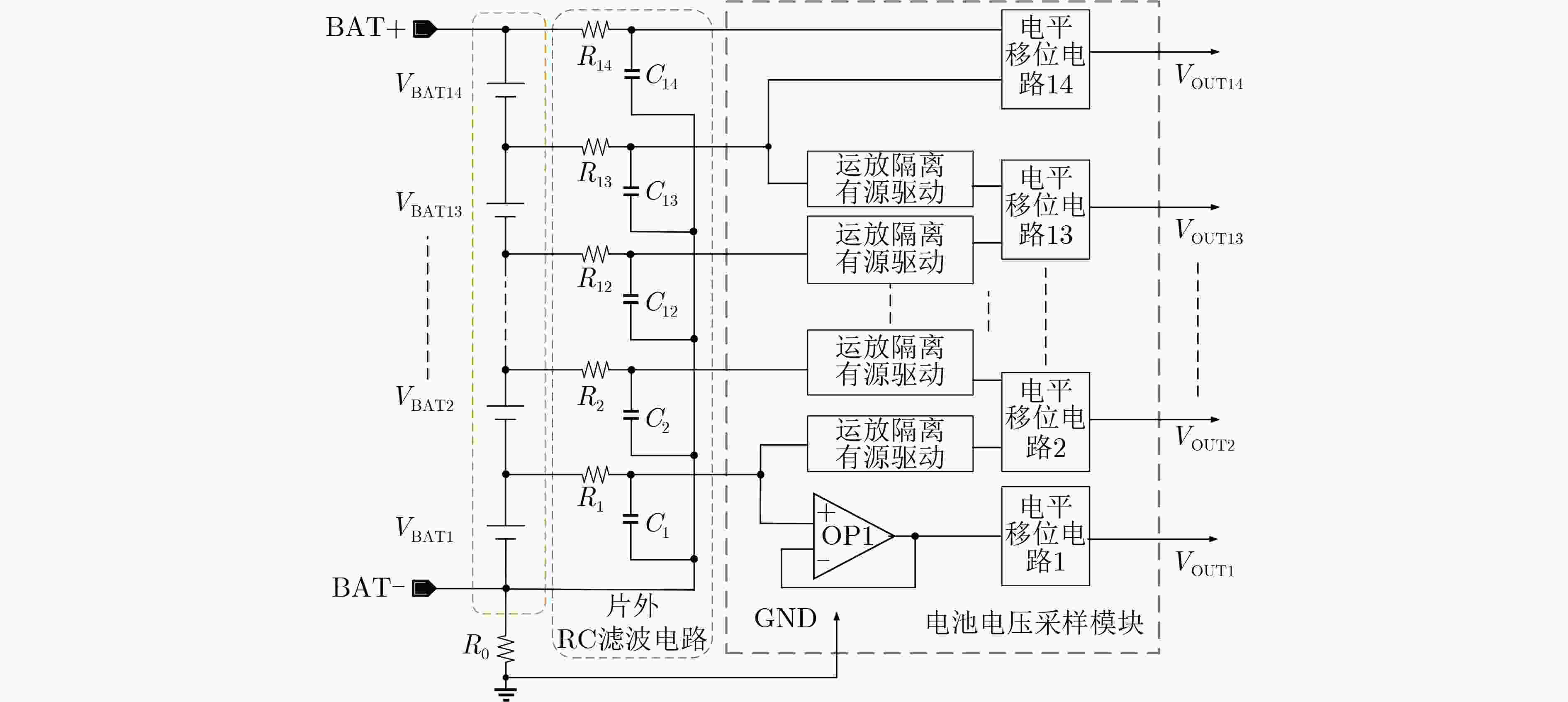

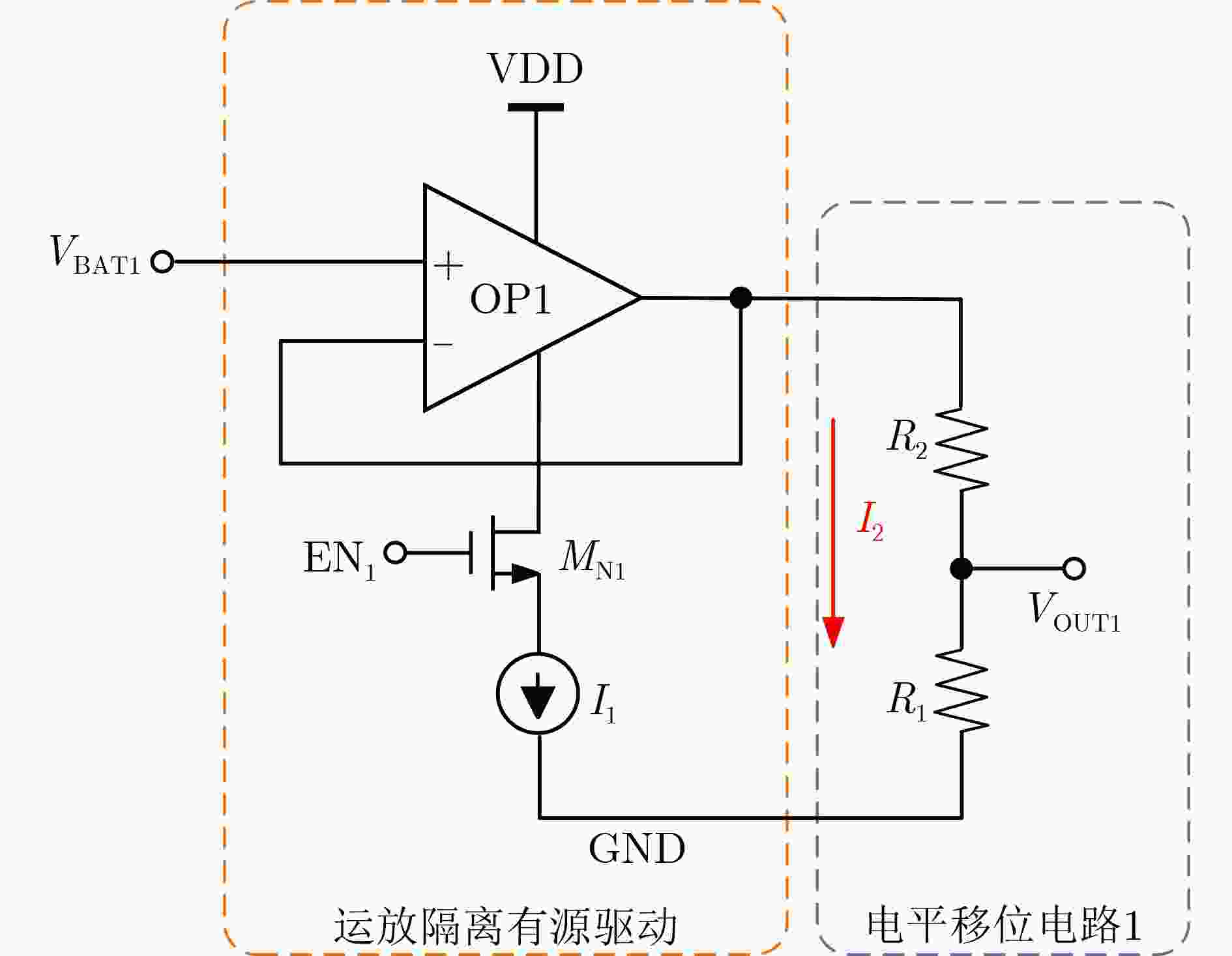

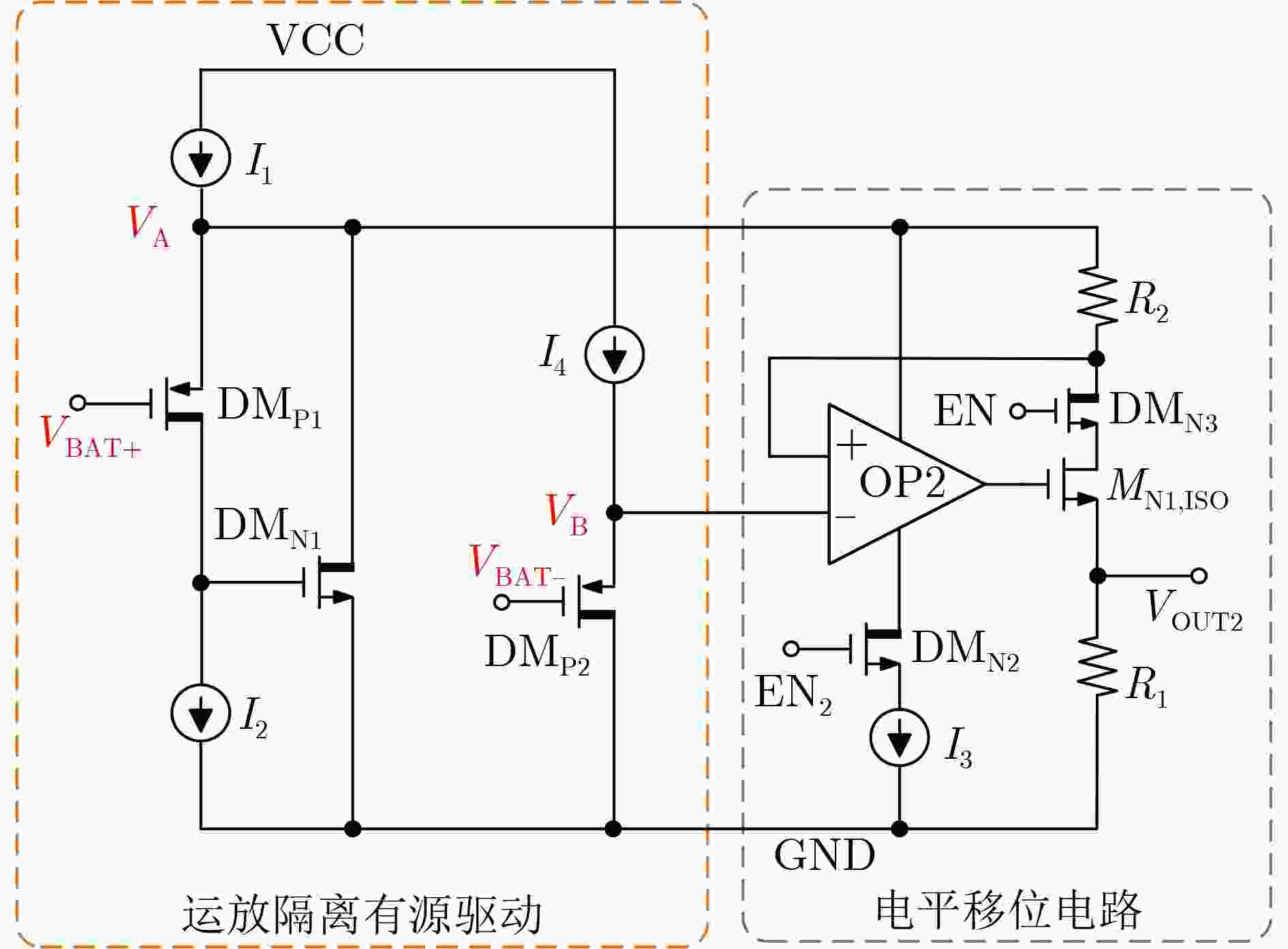

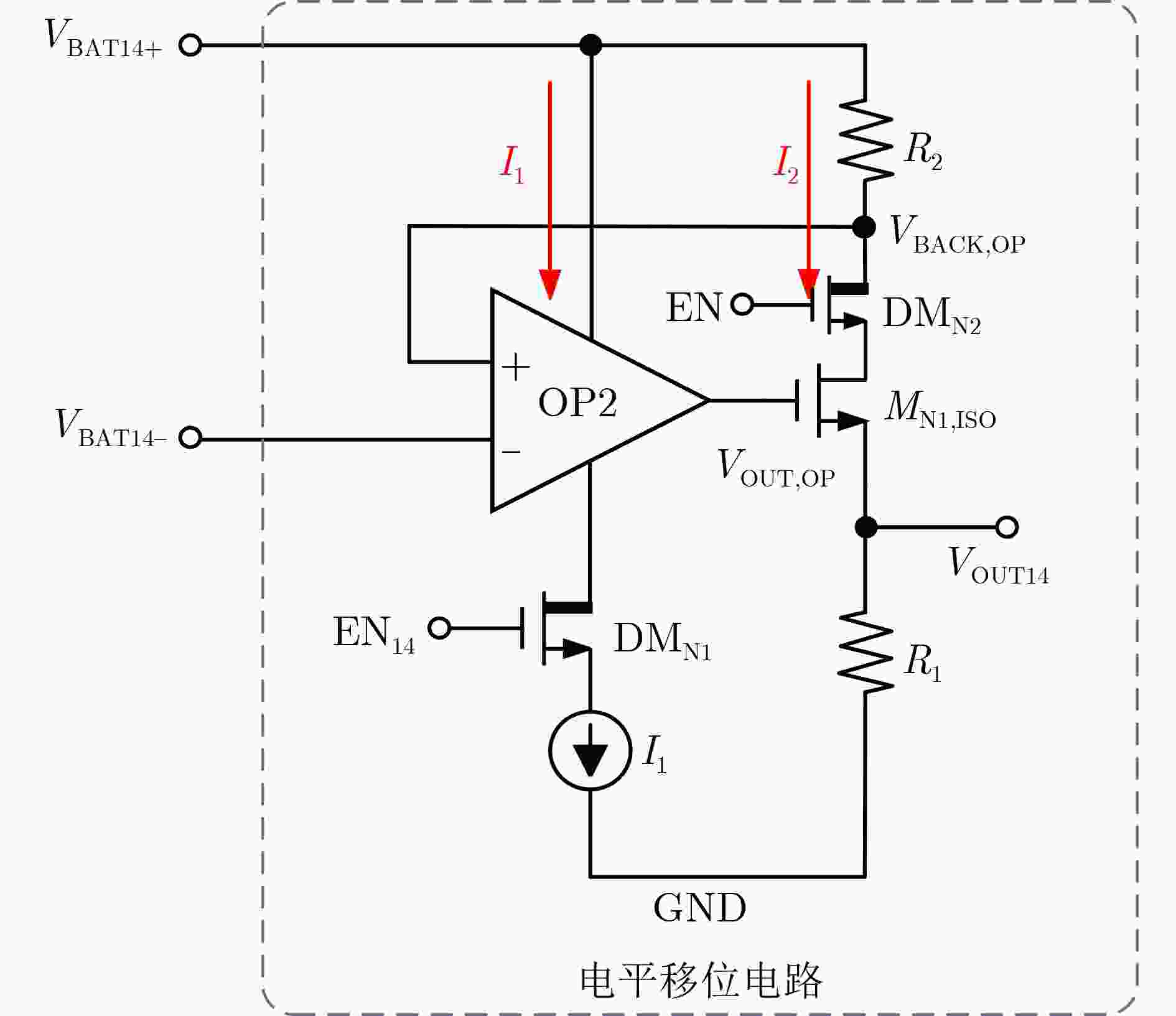

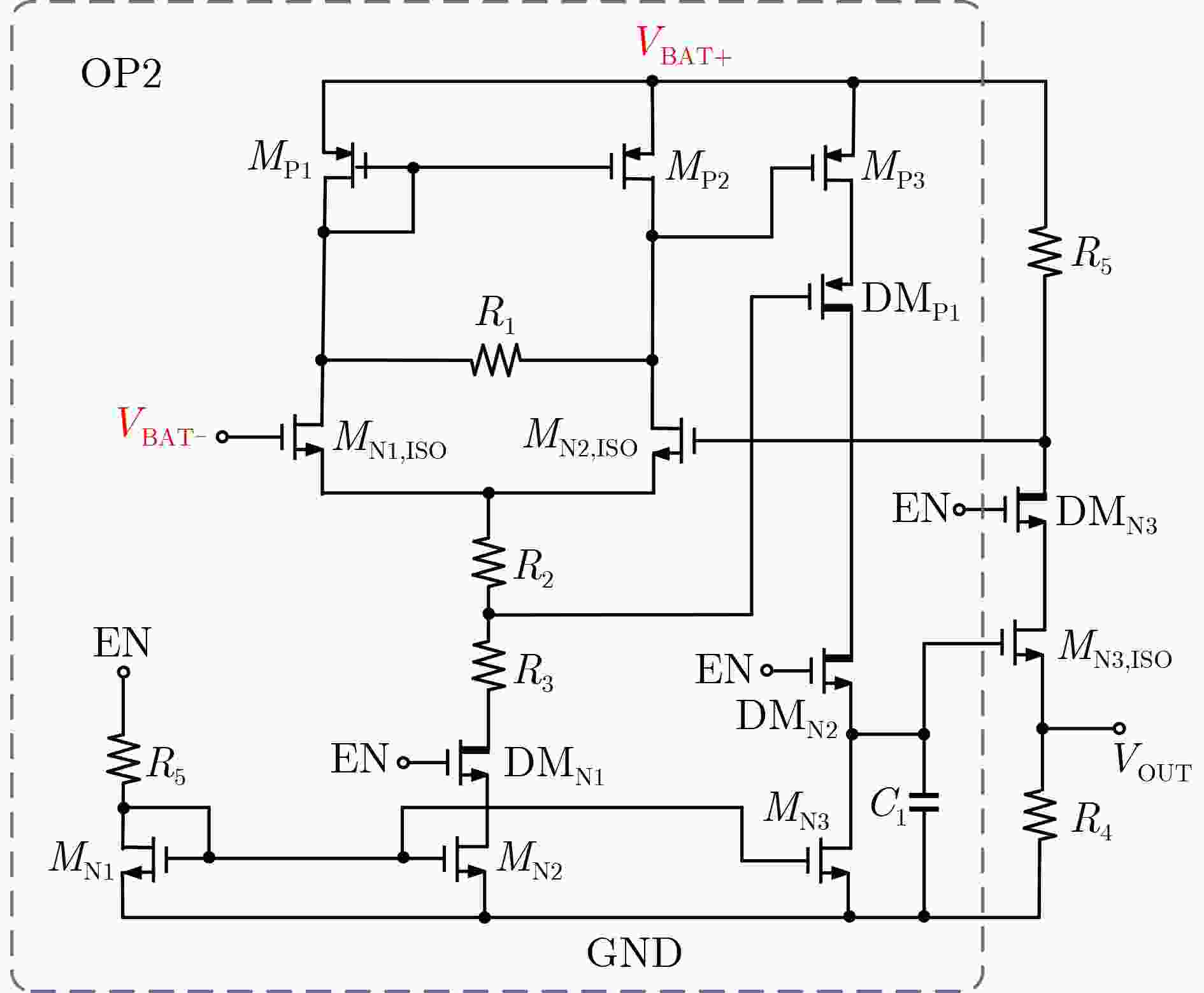

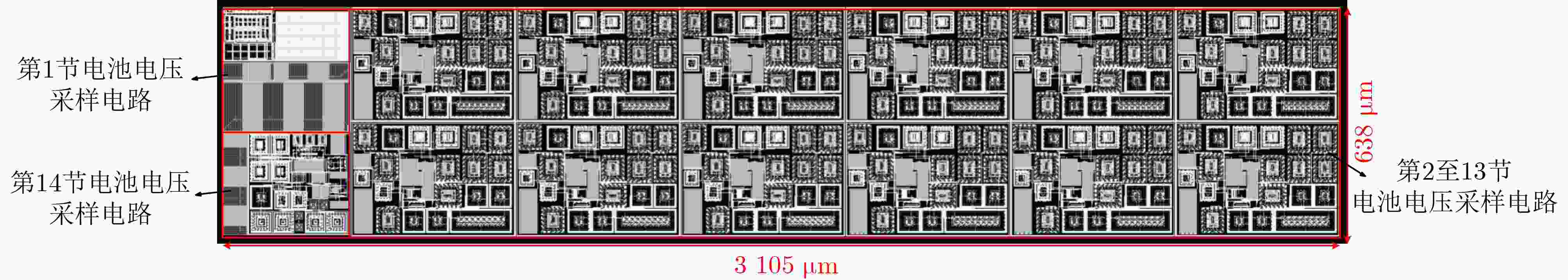

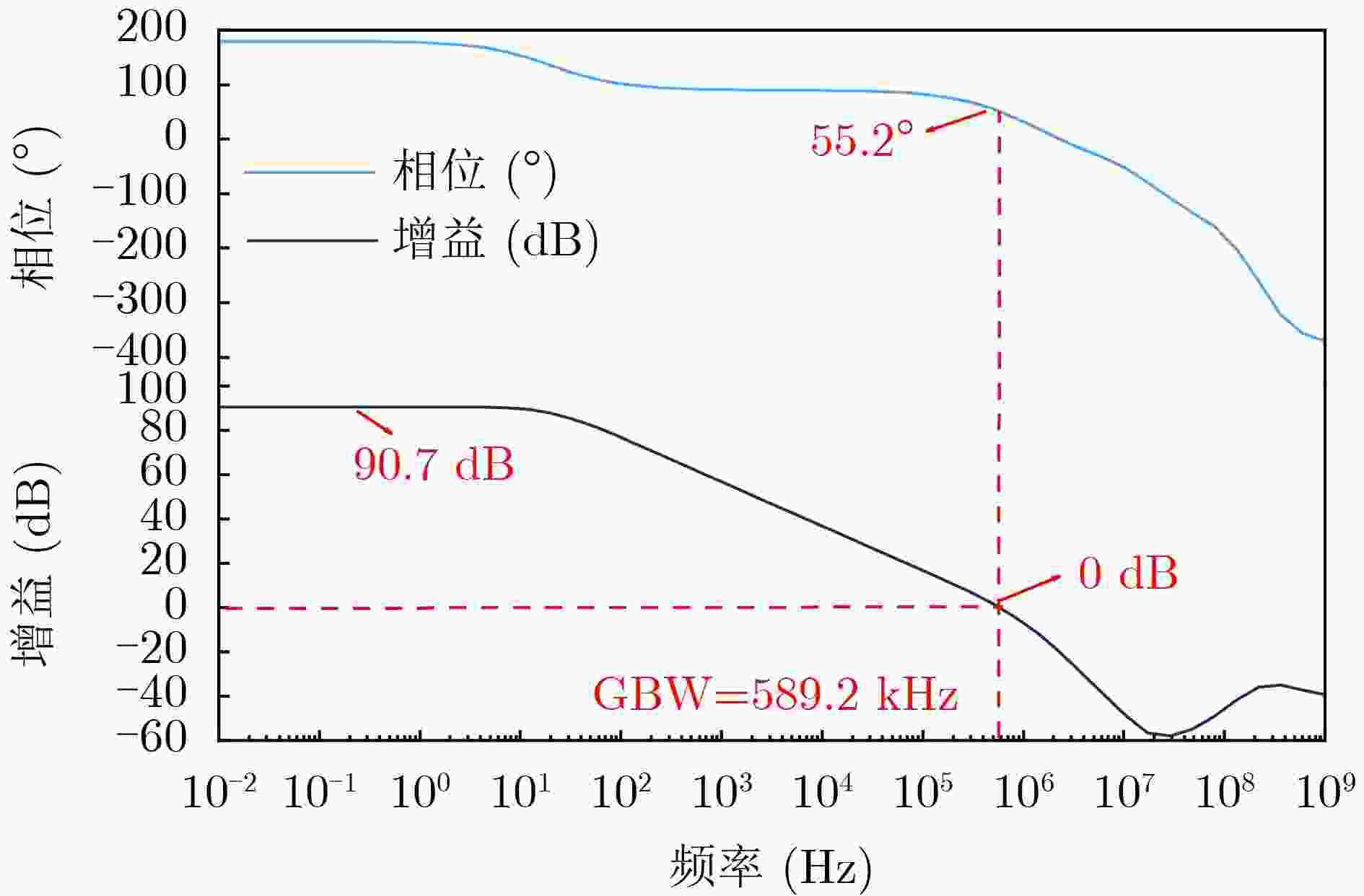

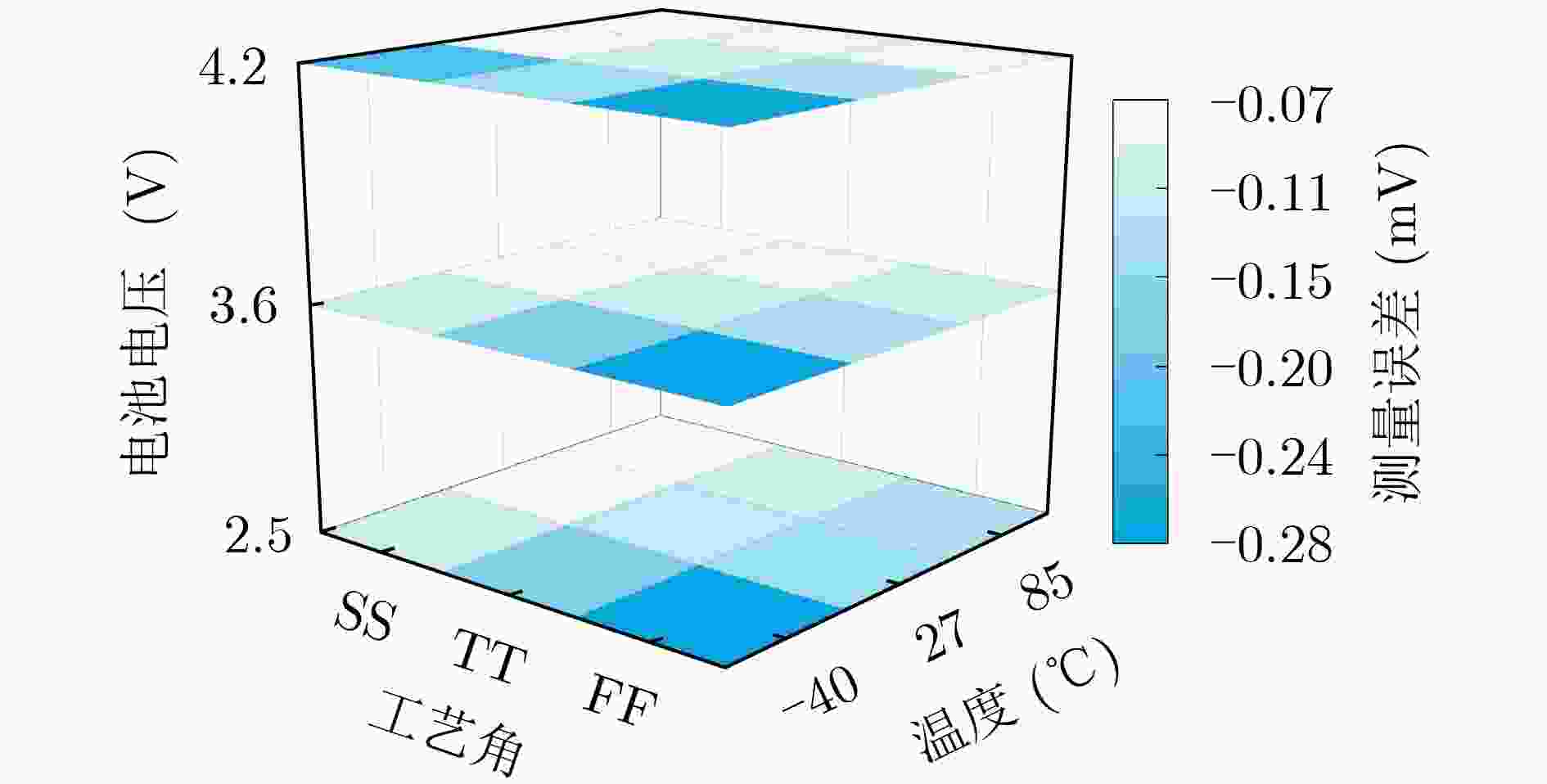

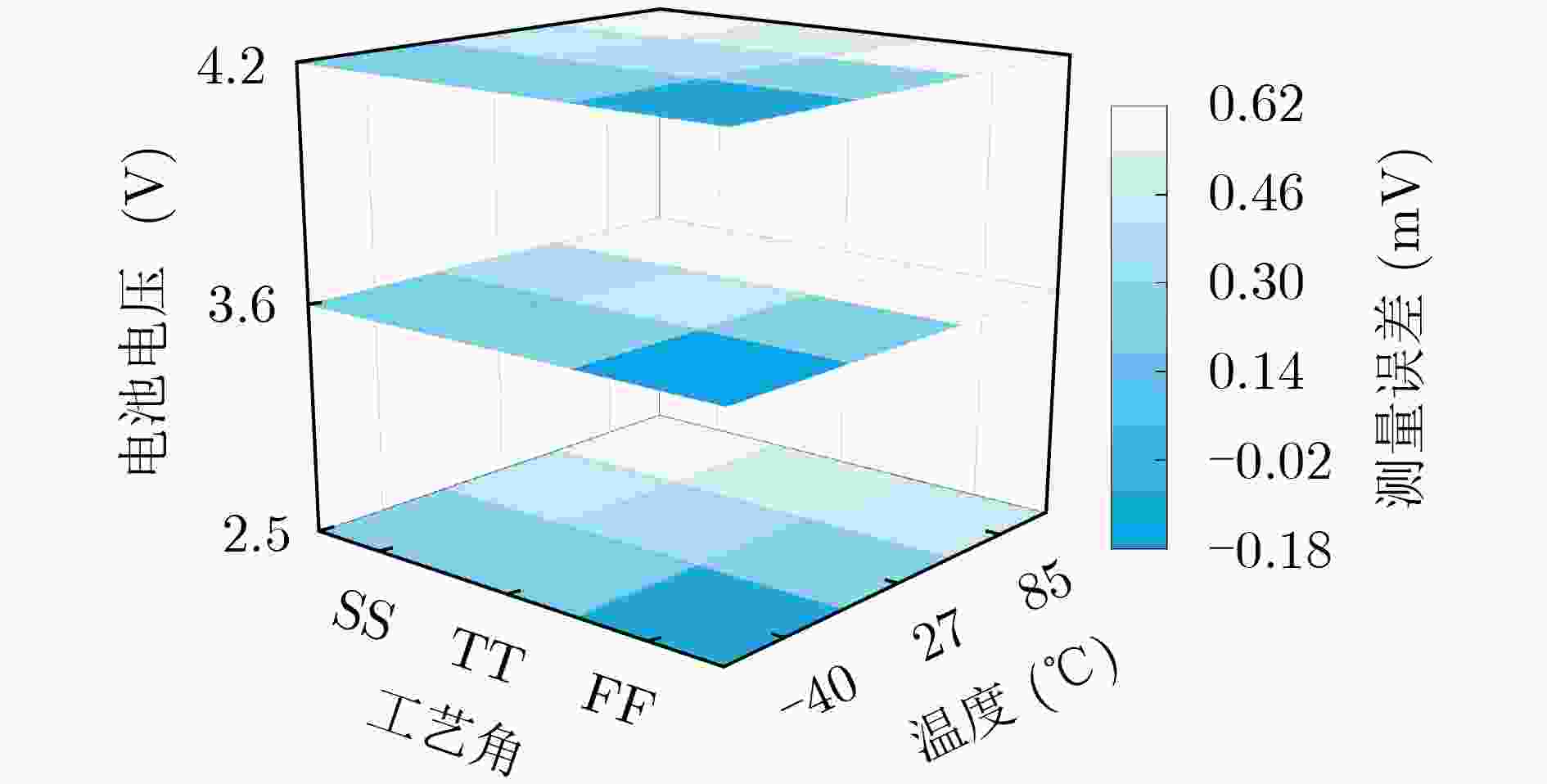

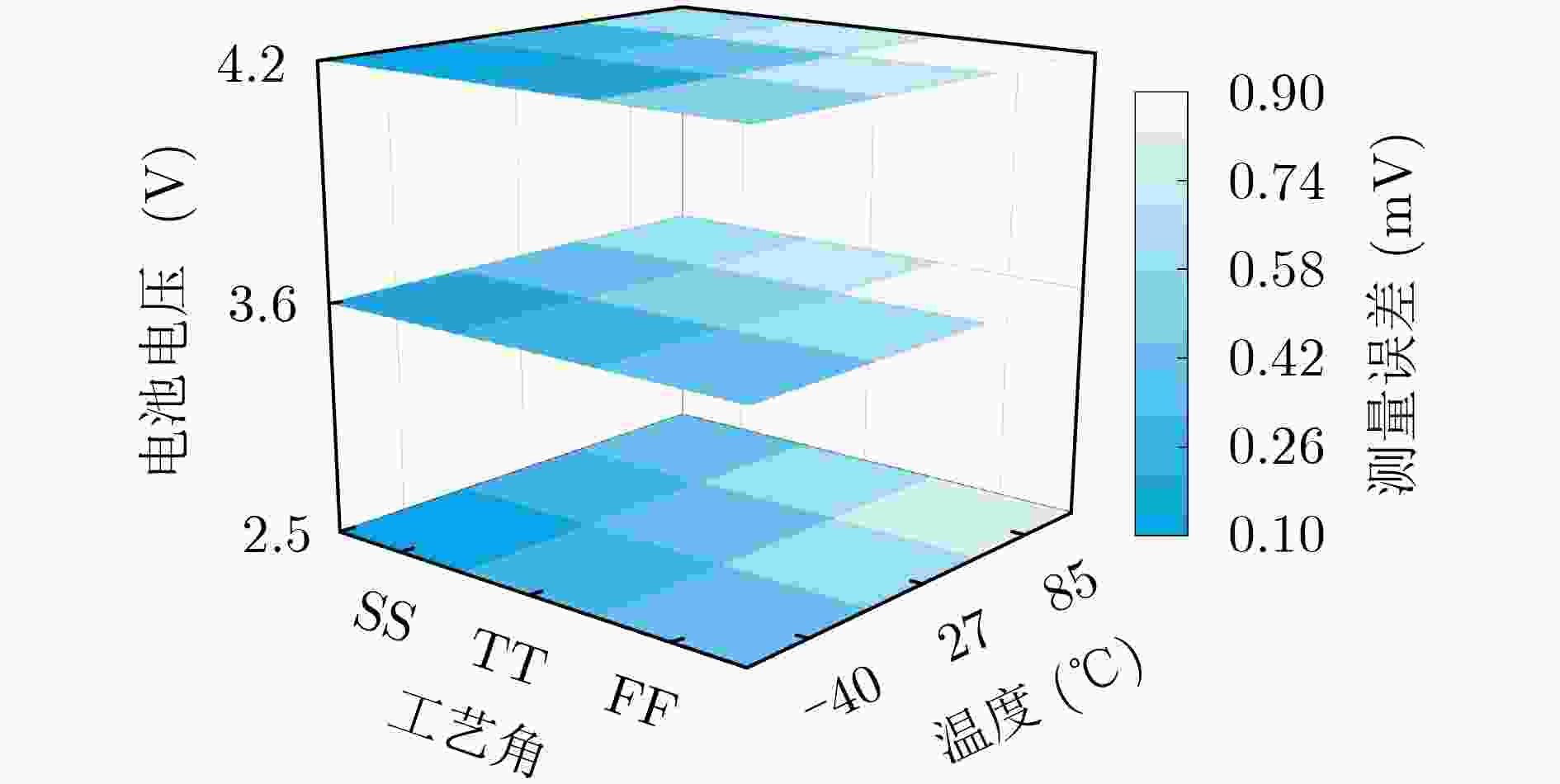

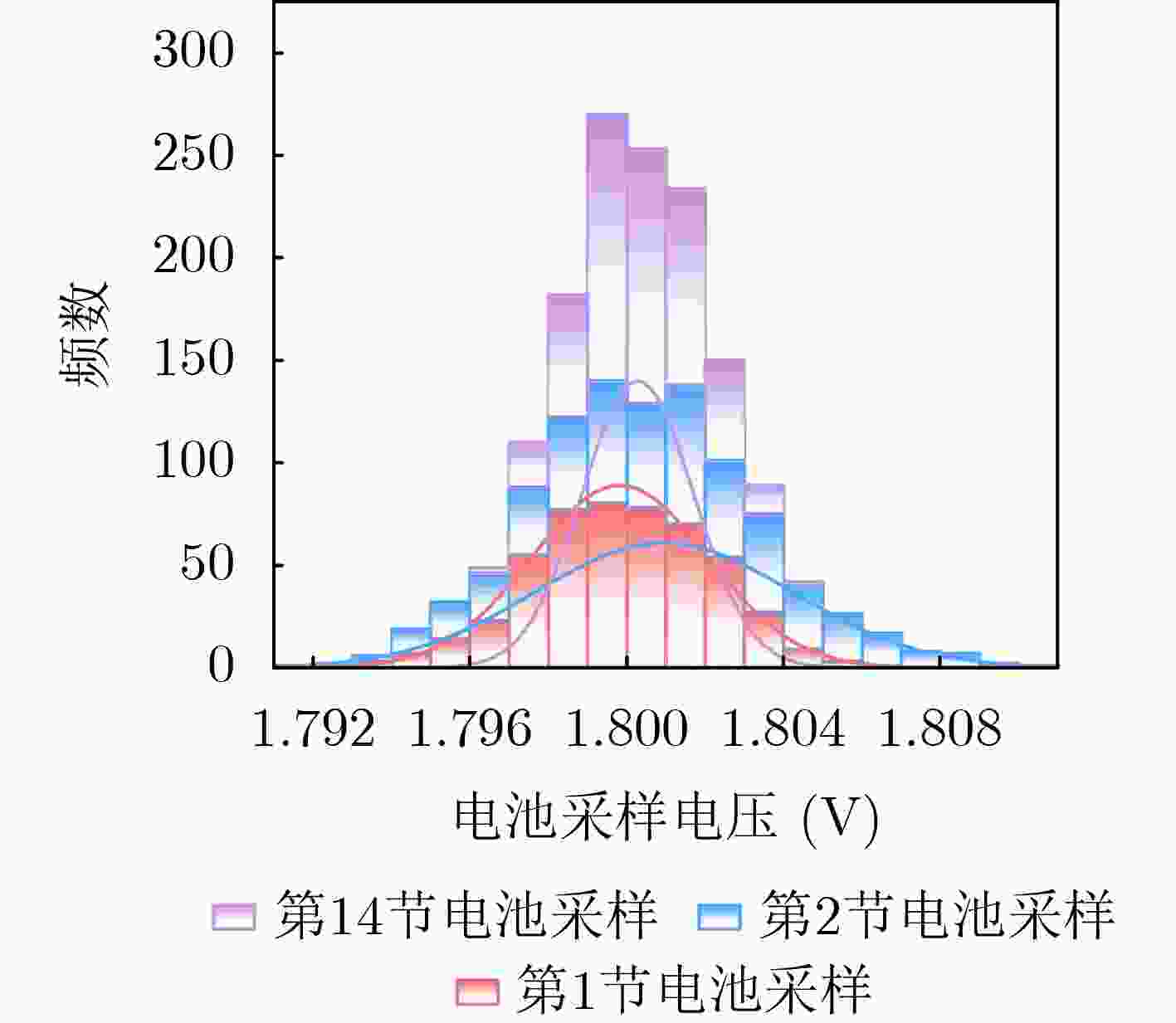

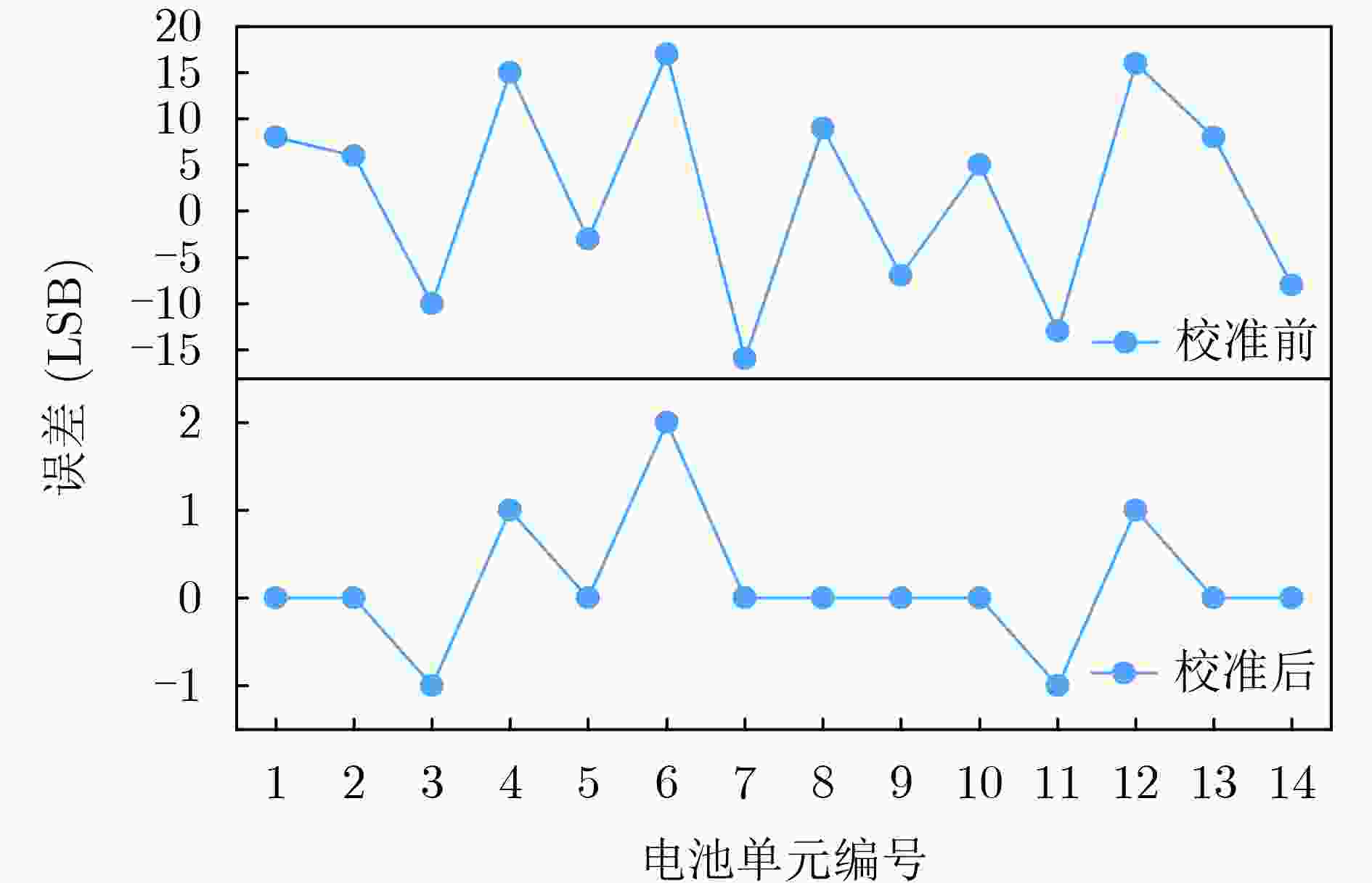

Objective The battery voltage sampling circuit is one of the key components of the Battery Management Integrated Circuit (BMIC). It is responsible for real-time monitoring of the battery’s voltage status, and its working performance directly determines the safety status of the series battery pack. The traditional resistive voltage sampling circuit has the problem of channel leakage current, which will affect the consistency of battery voltage and sampling accuracy. Meanwhile, the level-shifting circuit in the high-voltage domain includes high-voltage operational amplifiers, and a large number of high-voltage MOSFETs result in additional area overhead. Methods This paper proposes a low leakage current battery voltage sampling circuit applied to 14-series lithium batteries. Improved on the basis of the traditional resistive voltage sampling circuit, the channel leakage current can be reduced to the pA level by designing an operational amplifier isolated active drive technology. According to the different voltage domains of the series battery pack, different voltage conversion methods are adopted. The first section of the battery is isolated using a unity-gain buffer, and then voltage conversion is performed through a resistive voltage division method. Batteries from Section 2 to 13 adopt operational amplifier isolated active driving to synchronously follow the voltage across the batteries, and then convert the followed voltage into a ground-referenced voltage through a level-shifting circuit. The voltage sampling process of the highest-section battery consumes the power of the entire series battery pack and will not affect the consistency of the series battery pack. Therefore, the highest-section battery directly uses the level-shifting circuit for voltage conversion. Results and Discussions This paper conducts a detailed design and complete performance verification of the circuit based on the 0.35 μm high-voltage BCD process. The overall layout area of the designed battery voltage sampling circuit is 3105 μm × 638 μm (Fig. 10 ). From the verification results, it can be concluded that under the different processes and temperatures, after adopting the operational amplifier isolated active drive technology designed in this paper, the maximum channel leakage current is only 48.9 pA. However, the minimum channel leakage current of the traditional voltage sampling circuit is 1.169×106 pA (Fig. 12 ,Fig. 13 ). Reduce the impact of the sampling process on battery inconsistency from 18.56% to 2.122 ppm (Fig. 14 ). In addition, under comprehensive PVT verification conditions, the maximum measurement error of the battery voltage sampling circuit designed in this paper is 0.9 mV (Fig. 15 ,Fig. 16 ,Fig. 17 ).Conclusions This paper proposes an operational amplifier isolated active drive technology to mitigate the issue in traditional resistive voltage sampling circuits where channel leakage current affects battery voltage consistency and sampling accuracy. Through the battery voltage sampling circuit designed in this paper, the maximum channel leakage current is 48.9 pA, the inconsistency of battery voltage is 2.122 ppm, and the maximum measurement error is 1.25 mV. It can achieve extremely low channel leakage current while ensuring sampling accuracy. The low-leakage-current battery voltage sampling circuit proposed can be applied to the 14-series lithium battery management chip. -

表 1 文献对比

[18] [20] [21] [22] [23] [25] 本文 工艺(µm) 0.18 0.18 0.18 0.18 0.18 — 0.35 电池节数 16 4-7 3 17 7 16 14 通道漏电流补偿 — 电流镜

钳位反馈型电流镜

钳位反馈型运算放大器

钳位反馈型运算放大器

钳位反馈型— 运放隔离

有源驱动型最大通道漏电流 16.25 uA 58 nA 20.34 nA 30 nA 30 nA — 48.9 pA 最大测量误差(mV) ±0.21 — — ±2 ±1.92 ±2.8 ±1.25 版图面积(mm2) 3.245×3.112 0.95×0.82 — 2.92×3.23 — — 3.105×0.638 数据类型 S T T T S T S *T表示数据类型为测试数据,S表示数据类型为仿真数据 -

[1] NIU Huizhe, ZHANG Nan, LU Ying, et al. Strategies toward the development of high-energy-density lithium batteries[J]. Journal of Energy Storage, 2024, 88: 111666. doi: 10.1016/j.est.2024.111666. [2] MALIK G R, REDDY K V T, REDDY Y P K, et al. Future of energy storage: Advancements in lithium-ion batteries and hybrid vehicle technologies[C]. 2024 7th International Conference on Circuit Power and Computing Technologies, Kollam, India, 2024: 1887–1892. doi: 10.1109/ICCPCT61902.2024.10672664. [3] LEI Yu, XU Lulu, CHAN Qingnian, et al. Recent advances in separator design for lithium metal batteries without dendrite formation: Implications for electric vehicles[J]. eTransportation, 2024, 20: 100330. doi: 10.1016/j.etran.2024.100330. [4] TIMILSINA L, BADR P R, HOANG P H, et al. Battery degradation in electric and hybrid electric vehicles: A survey study[J]. IEEE Access, 2023, 11: 42431–42462. doi: 10.1109/ACCESS.2023.3271287. [5] AKYILDIZ A, ERGUN B E, UZUN E, et al. Optimum selection of lithium iron phosphate battery cells for electric vehicles[J]. IEEE Access, 2025, 13: 55070–55080. doi: 10.1109/ACCESS.2025.3553081. [6] PESARAN A A. Lithium-ion battery technologies for electric vehicles: Progress and challenges[J]. IEEE Electrification Magazine, 2023, 11(2): 35–43. doi: 10.1109/MELE.2023.3264919. [7] LI Qingwei and XUE Wenli. A review of feature extraction toward health state estimation of lithium-ion batteries[J]. Journal of Energy Storage, 2025, 12: 115453. doi: 10.1016/j.est.2025.115453. [8] CUI Xiangming, WANG Jingzhao, SUN Shiyi, et al. Safety hazards of lithium metal batteries: From the perspective of lithium dendrites and thermal runaway[J]. Energy & Fuels, 2025, 39(16): 7665–7690. doi: 10.1021/acs.energyfuels.5c00728. [9] PING Ping, REN Xiantong, KONG Depeng, et al. Multi-scale thermal runaway analysis of sodium-ion batteries and comparative safety assessment with lithium-ion batteries[J]. Composites Part B: Engineering, 2025, 302: 112532. doi: 10.1016/j.compositesb.2025.112532. [10] YIN Deyou, NI Jimin, SHI Xiuyong, et al. Dynamic overcharge performance and mechanism of lithium-ion batteries during high-temperature calendar aging[J]. ACS Applied Energy Materials, 2025, 8(6): 3491–3499. doi: 10.1021/acsaem.4c03015. [11] LIU Zijun, HAN Kuihua, ZHANG Qiang, et al. Thermal safety focus and early warning of lithium-ion batteries: A systematic review[J]. Journal of Energy Storage, 2025, 115: 115944. doi: 10.1016/j.est.2025.115944. [12] RAGCHAA B, WU Liji, and ZHANG Xiangmin. A design of fault-tolerant battery monitoring IC for electric vehicles complying with ISO 26262[J]. IEEE Open Journal of Circuits and Systems, 2024, 5: 166–177. doi: 10.1109/OJCAS.2024.3391829. [13] VULLIGADDALA V B, VERNEKAR S, SINGAMLA S, et al. A 7-cell, stackable, Li-ion monitoring and active/passive balancing IC with in-built cell balancing switches for electric and hybrid vehicles[J]. IEEE Transactions on Industrial Informatics, 2020, 16(5): 3335–3344. doi: 10.1109/TII.2019.2953939. [14] YUE Tai, WU Liji, ZHANG Xiangmin, et al. High-precision voltage measurement IP core for battery management SoC of electric vehicles[C]. 2014 12th IEEE International Conference on Solid-State and Integrated Circuit Technology (ICSICT), Guilin, China, 2014: 1–3. doi: 10.1109/ICSICT.2014.7021570. [15] CHEN Zhijian, WU Xinyi, LI Bin, et al. A novel voltage protection method for multi-cell lithium-ion battery protection IC[J]. Journal of Physics: Conference Series, 2022, 2313(1): 012014. doi: 10.1088/1742-6596/2313/1/012014. [16] WU Qi and WU Jiangfeng. High precision voltage sampling circuit for battery management system[C]. 2024 IEEE 7th Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chongqing, China, 2024: 713–717. doi: 10.1109/IAEAC59436.2024.10503982. [17] WANG Xiaofei, ZHANG Hong, ZHANG Jianrong, et al. A multi-cell battery pack monitoring chip based on 0.35-µm BCD technology for electric vehicles[J]. IEICE Electronics Express, 2015, 12(12): 20150367. doi: 10.1587/elex.12.20150367. [18] HAO Yunqiang, YI Dongbai, ZHANG Xiaowei, et al. A power management IC used for monitoring and protection of Li-ion battery packs[J]. Journal of Sensors, 2021, 2021: 6611648. doi: 10.1155/2021/6611648. [19] SHI Qianqian, TANG Wei, and LV Qiushuang. A high precision voltage detection circuit for multiple lithium batteries[C]. 2022 7th International Conference on Integrated Circuits and Microsystems (ICICM), Xi'an, China, 2022: 60–66. doi: 10.1109/ICICM56102.2022.10011305. [20] WU Kaikai, WANG Hongyi, CHEN Chen, et al. Battery voltage transfer method for multi-cells Li-ion battery pack protection chips[J]. Analog Integrated Circuits and Signal Processing, 2022, 111(1): 13–24. doi: 10.1007/s10470-021-01836-9. [21] WU Kaikai, WANG Hongyi, CHEN Chen, et al. Improved voltage transfer method for lithium battery string management chip[J]. IET Circuits, Devices & Systems, 2021, 15(7): 649–656. doi: 10.1049/cds2.12060. [22] YOU Yong, ZHU Guangqian, LI Yongyuan, et al. 17-Cell battery monitoring analog front end with high sampling accuracy for battery pack applications[J]. Microelectronics Journal, 2024, 151: 106327. doi: 10.1016/j.mejo.2024.106327. [23] LI Qing, GUO Zhongjie, CHEN Hao, et al. High precision voltage monitoring technology for multi-cell battery management system[C]. 2020 IEEE 15th International Conference on Solid-State & Integrated Circuit Technology, Kunming, China, 2020. doi: 10.1109/ICSICT49897.2020.9278338. [24] 郭仲杰, 巩成军, 陈晅, 等. 应用于电池管理芯片中多通道电压采样不一致性校准方法[P]. 中国, 202410631286.7, 2024.GUO Zhongjie, GONG Chengjun, CHEN Xuan, et al. Multi-channel voltage sampling inconsistency calibration method applied to battery management chip[P]. CN, 202410631286.7, 2024. [25] http://www.ti.com.cn/product/cn/BQ79616-Q1, 2025. (查阅网上资料,请补充完整本条文献信息,请确认). -

下载:

下载:

下载:

下载: