Research on Parasitic Bipolar Inductance Absolute Angle Sensor

-

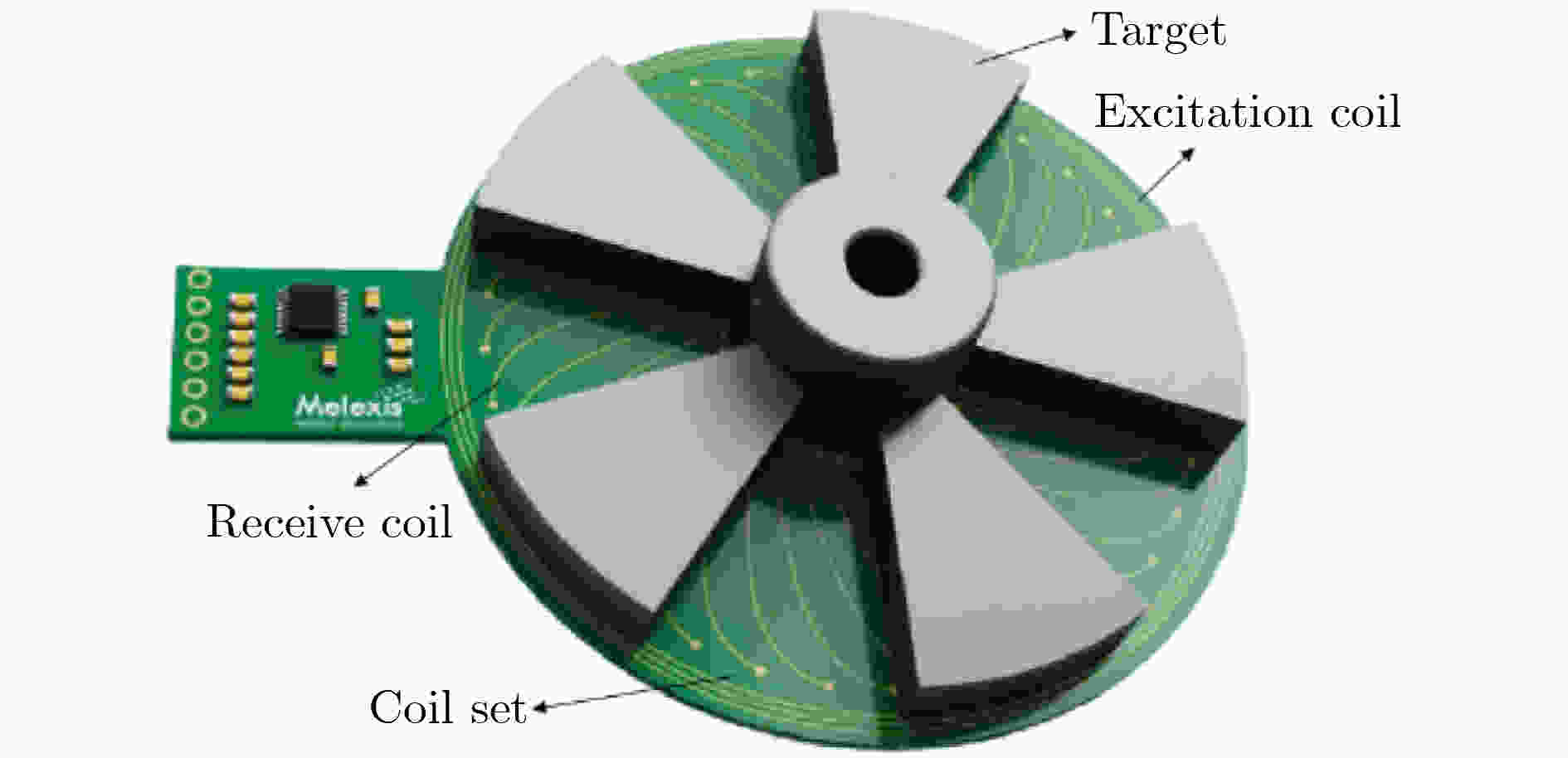

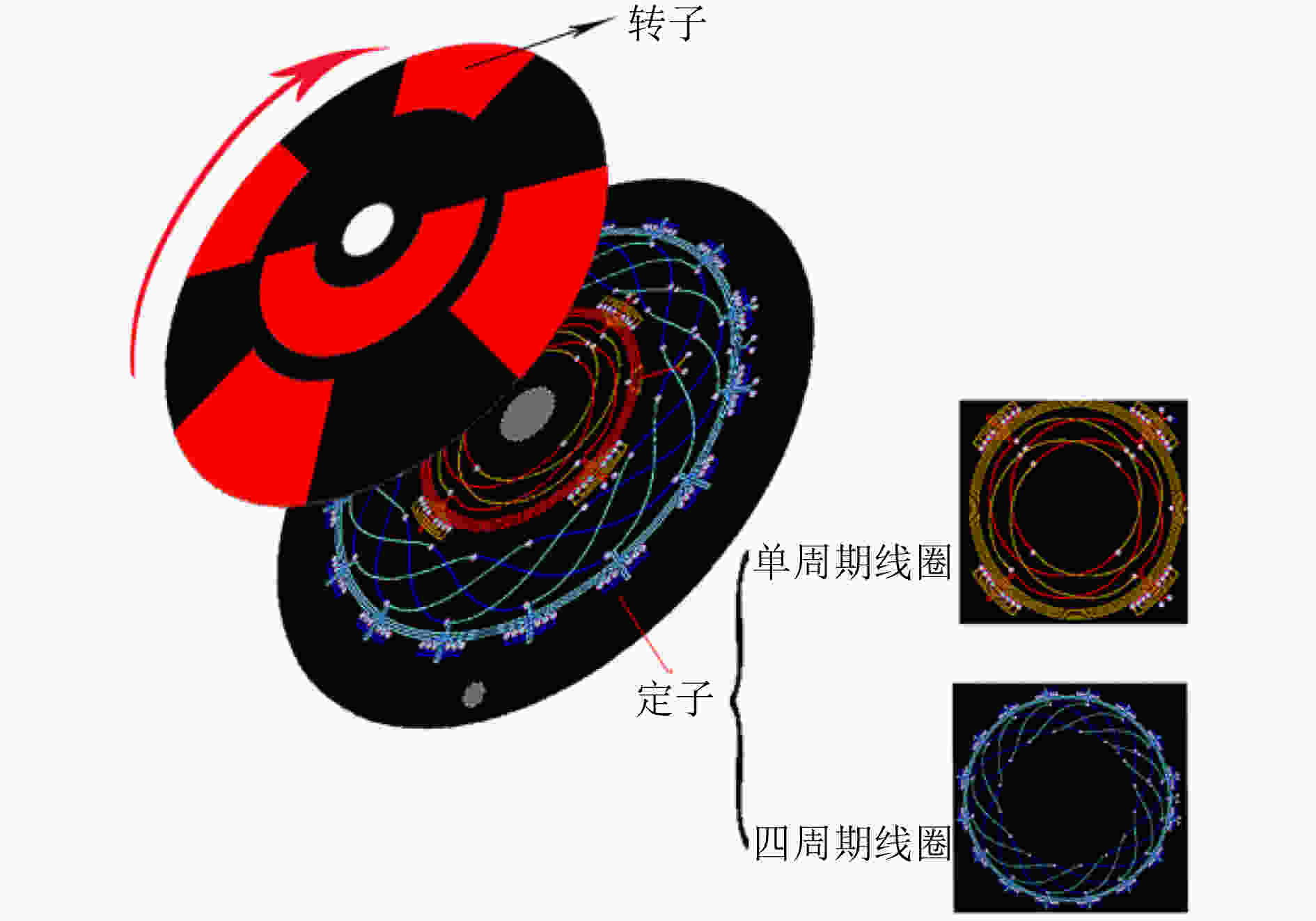

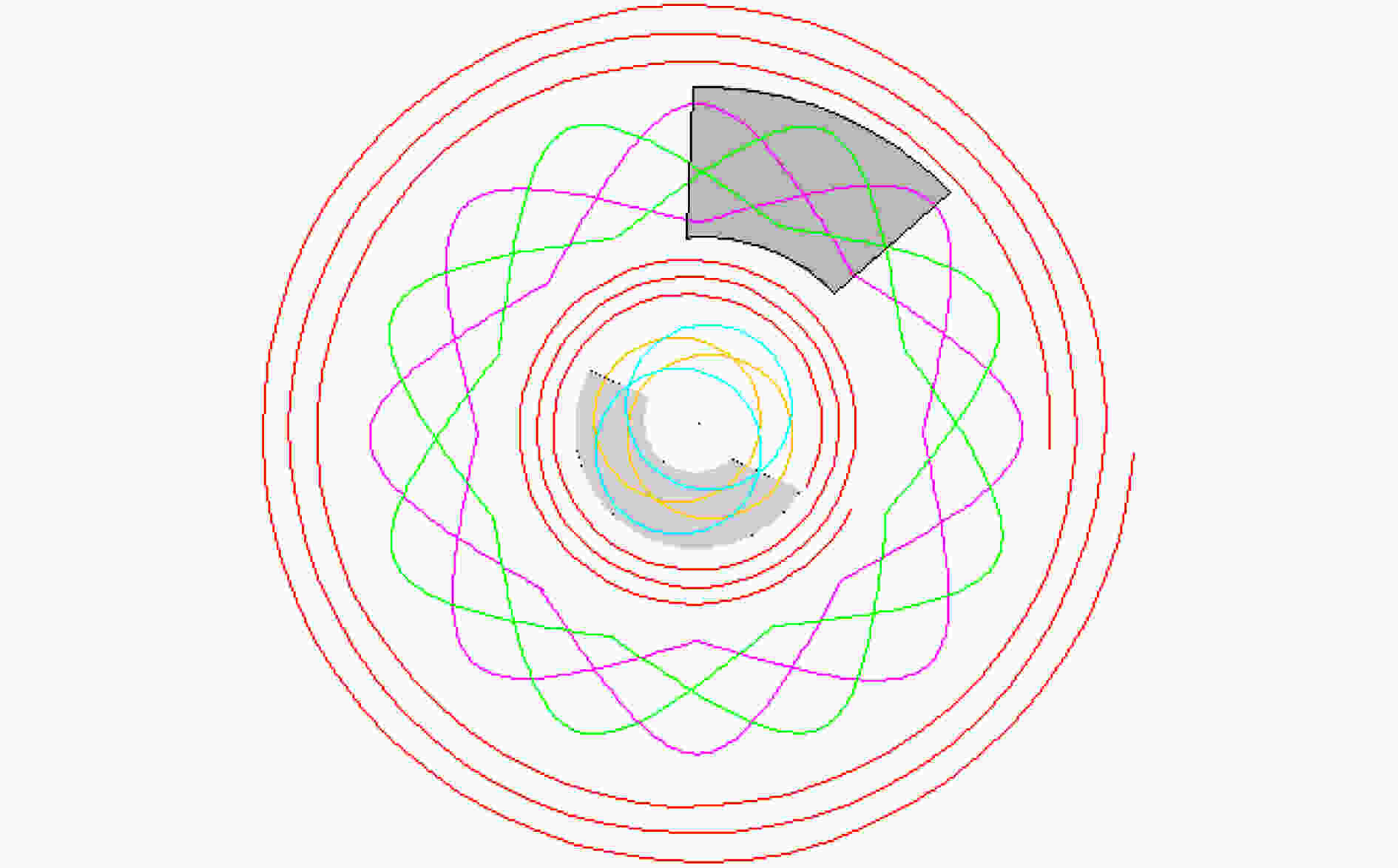

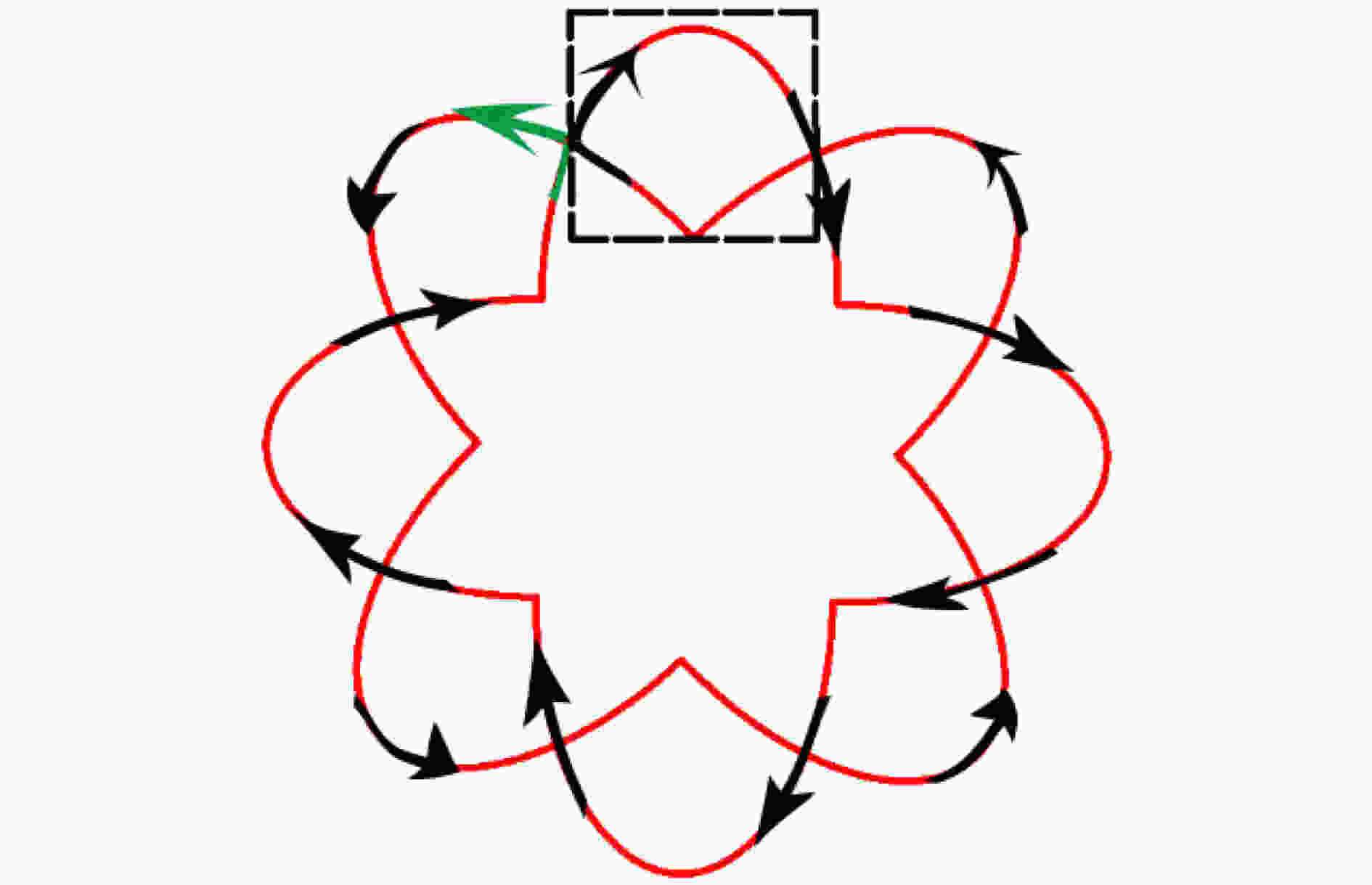

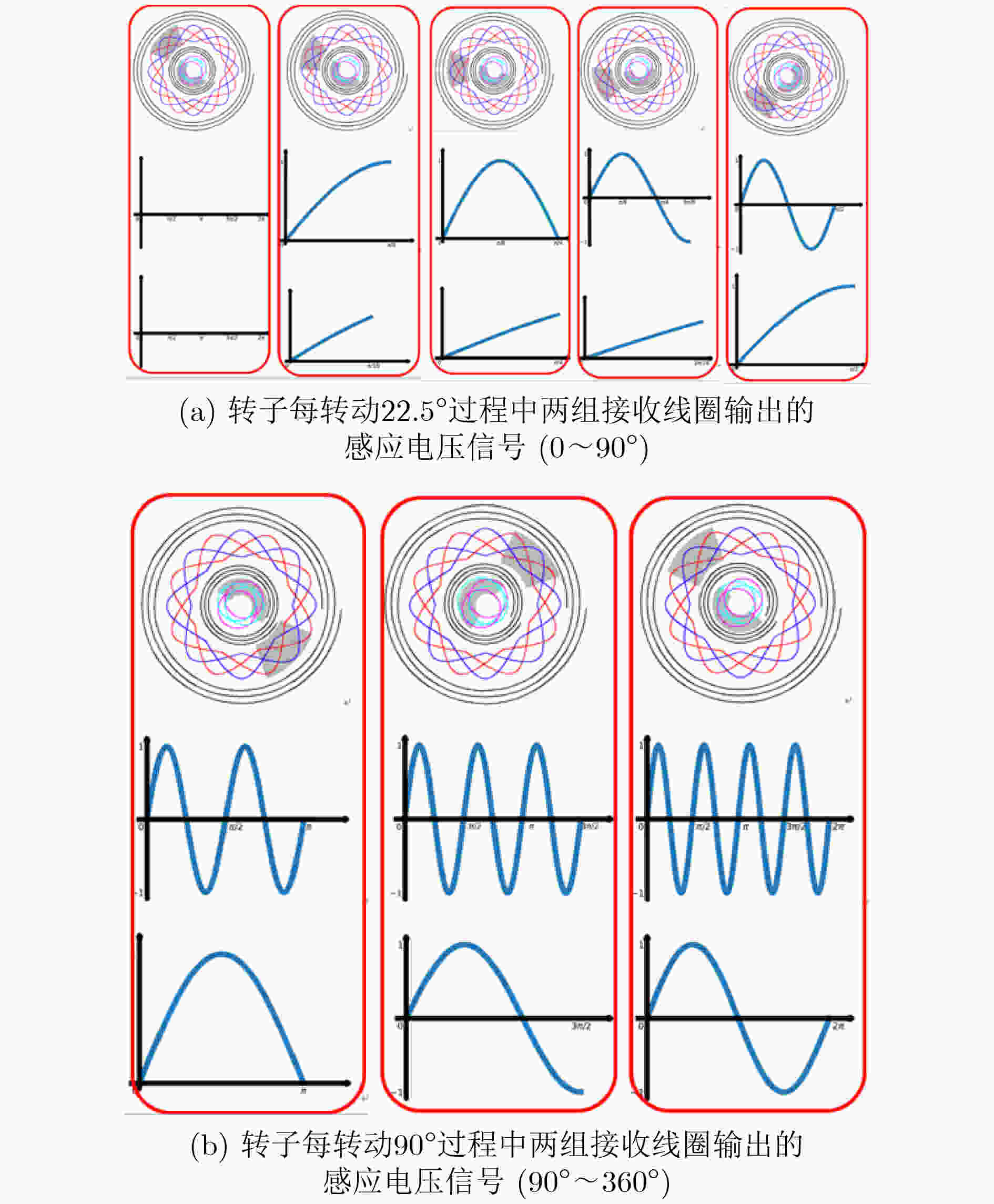

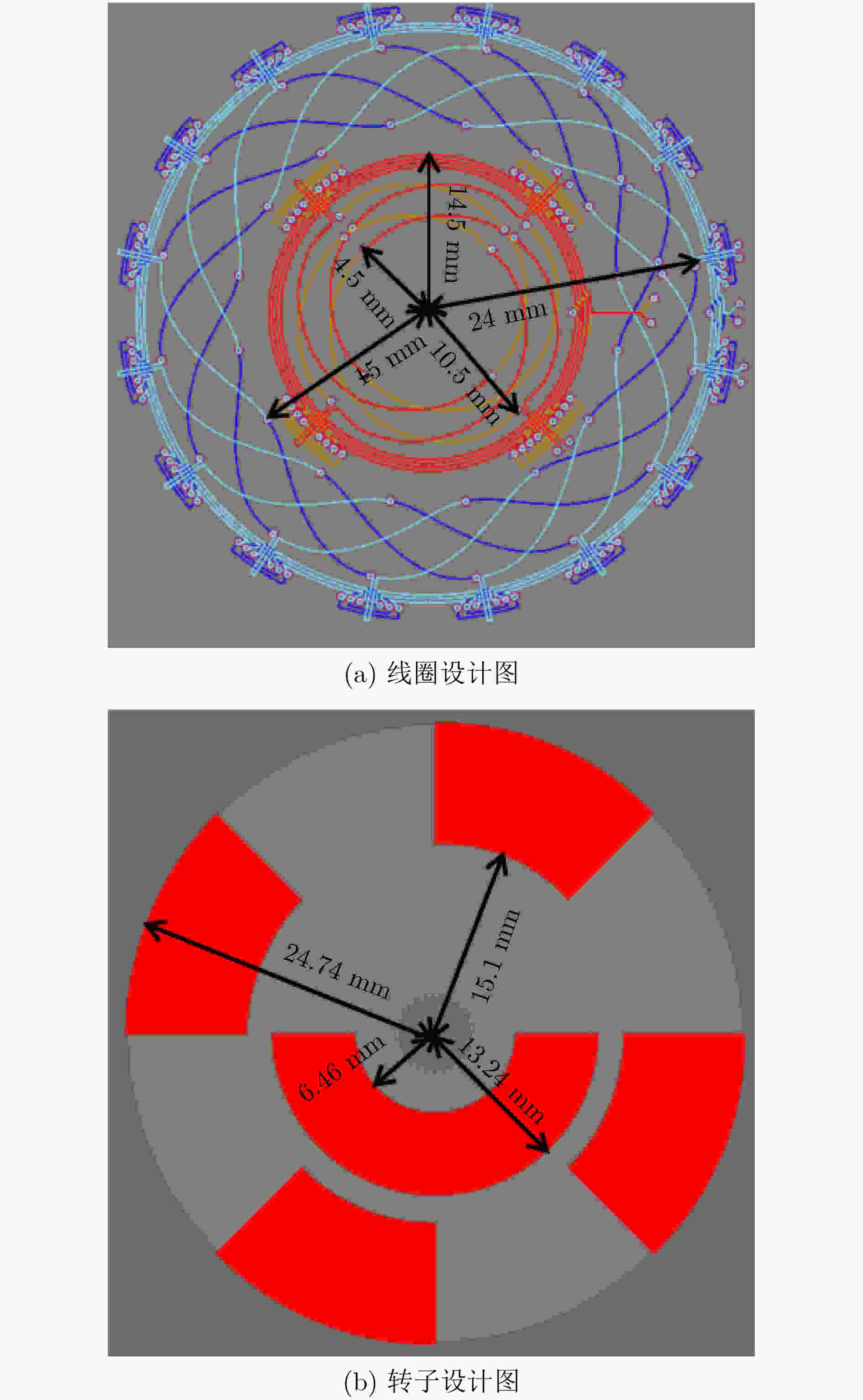

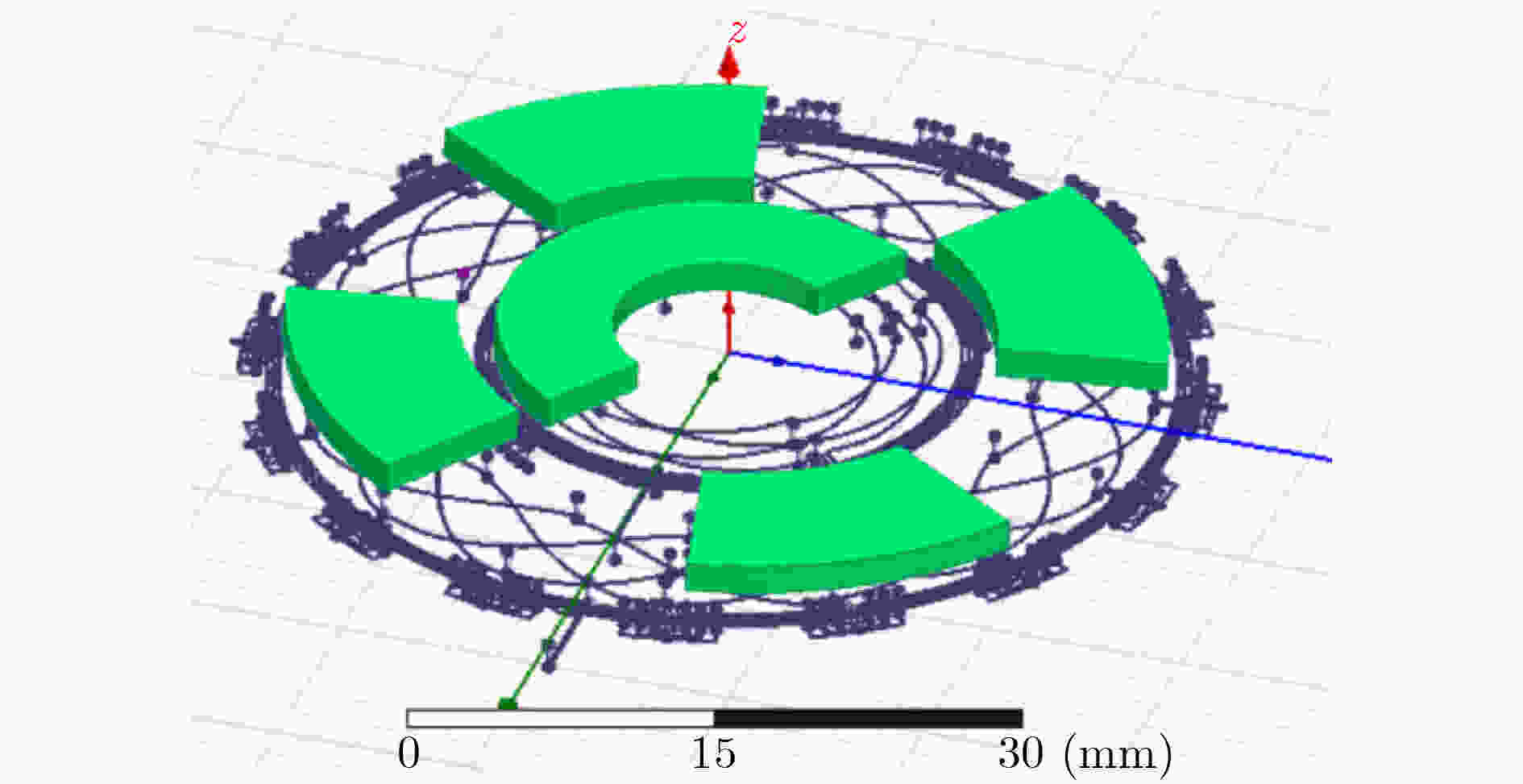

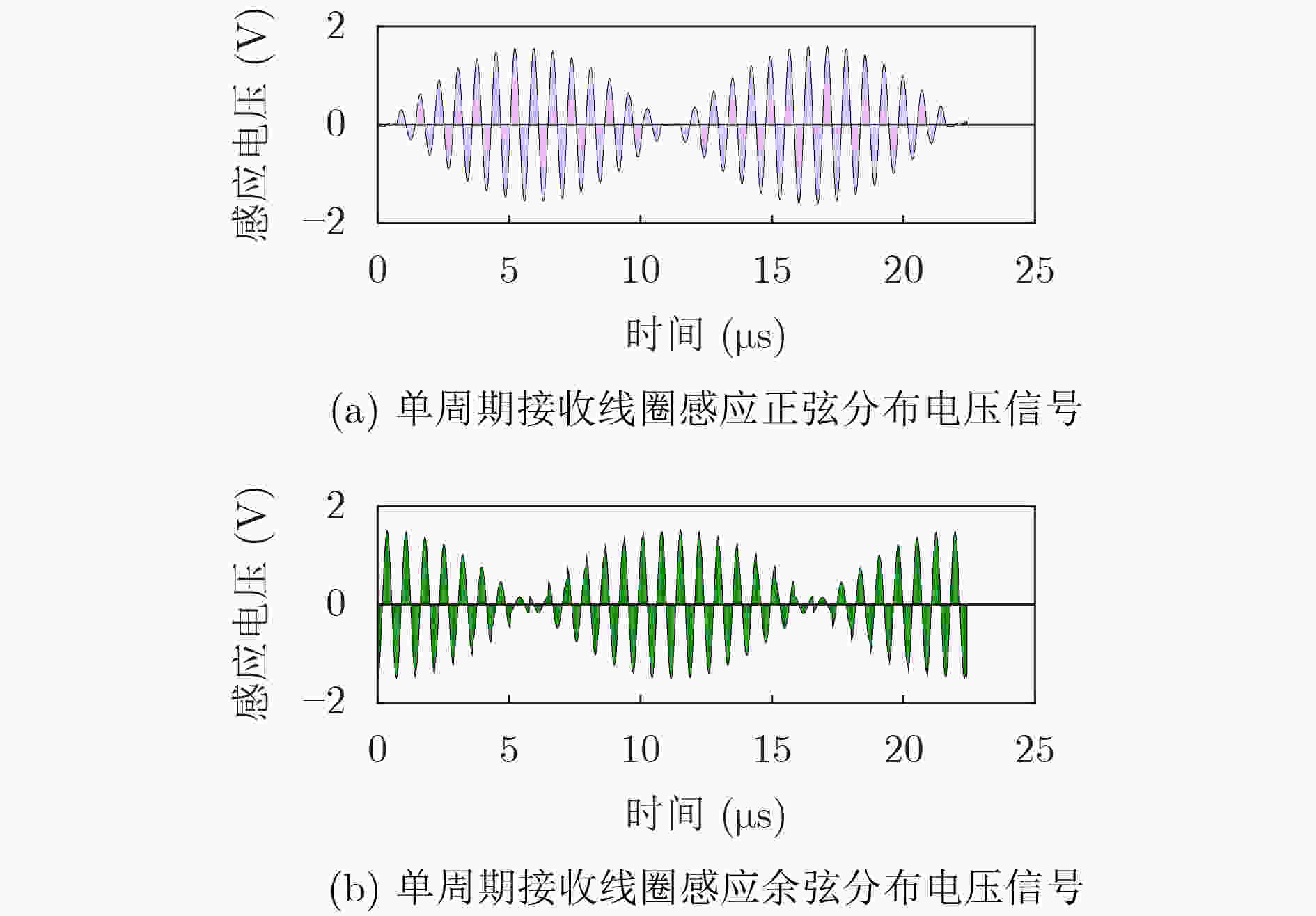

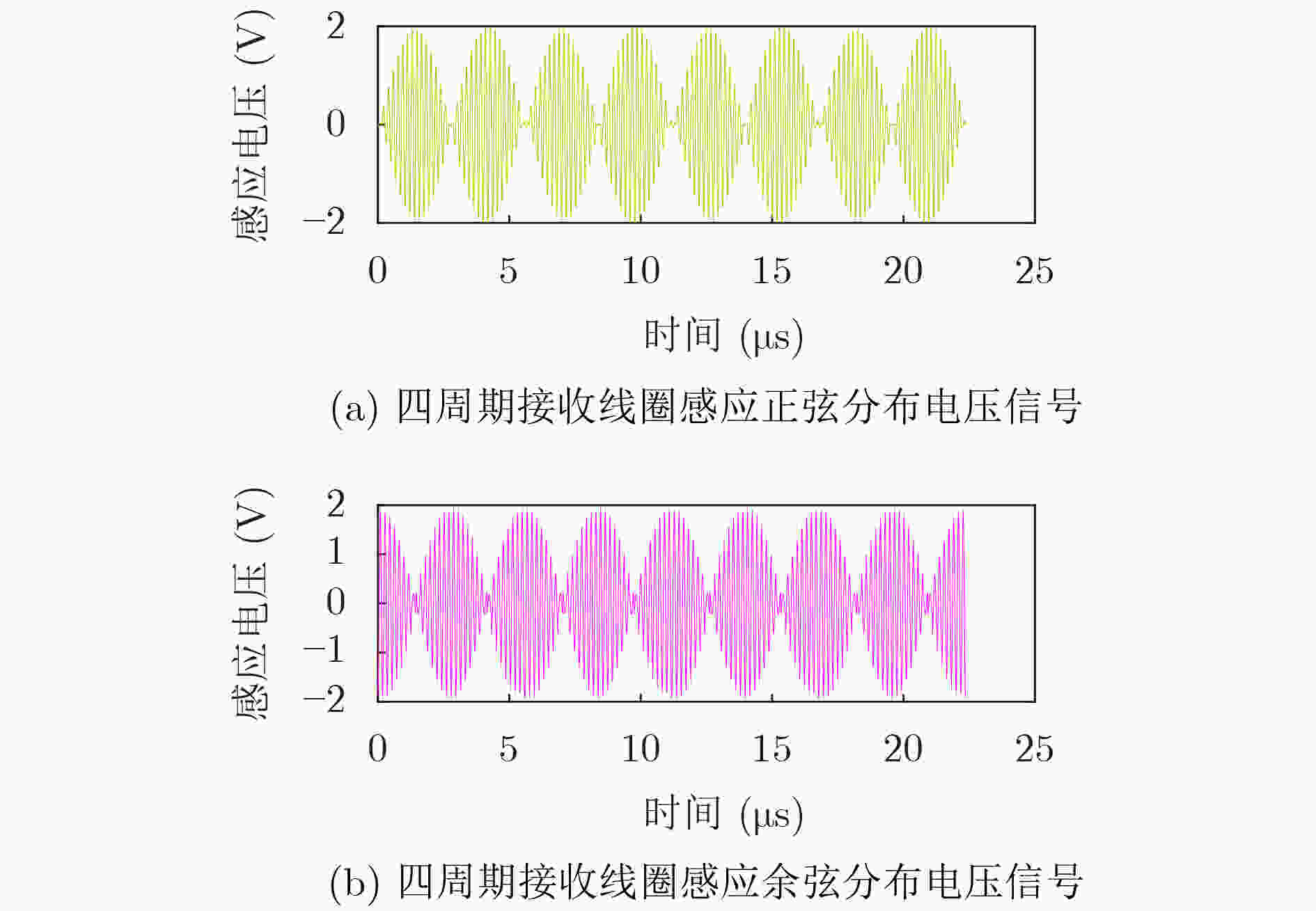

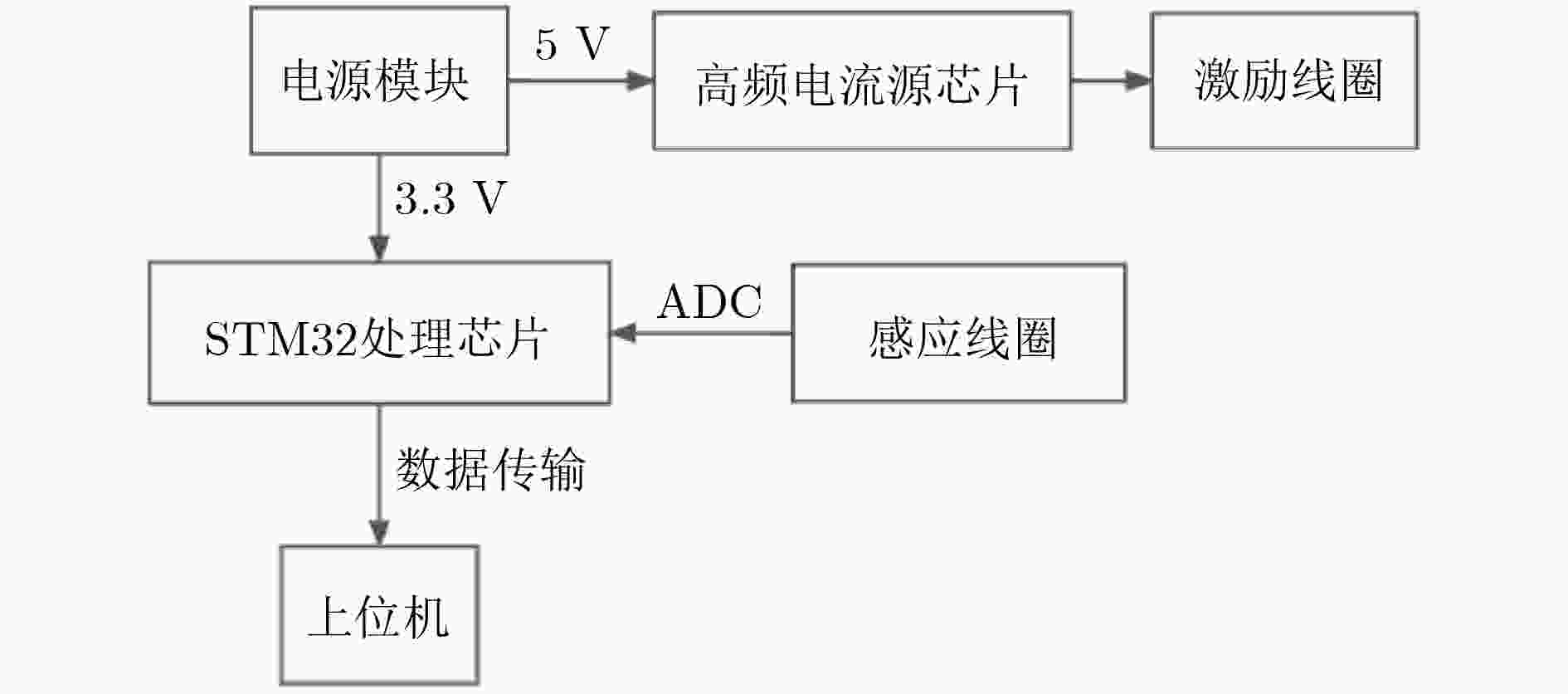

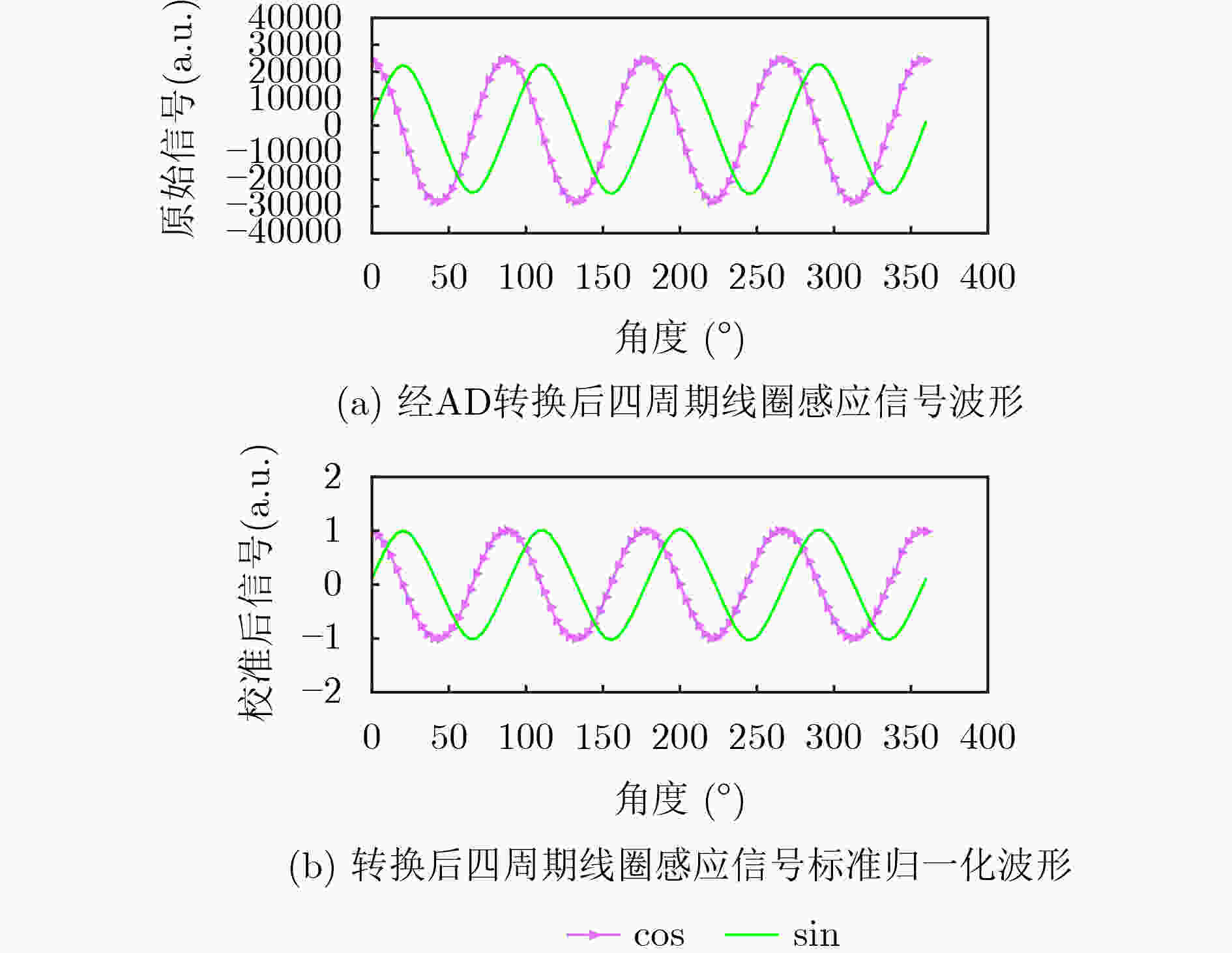

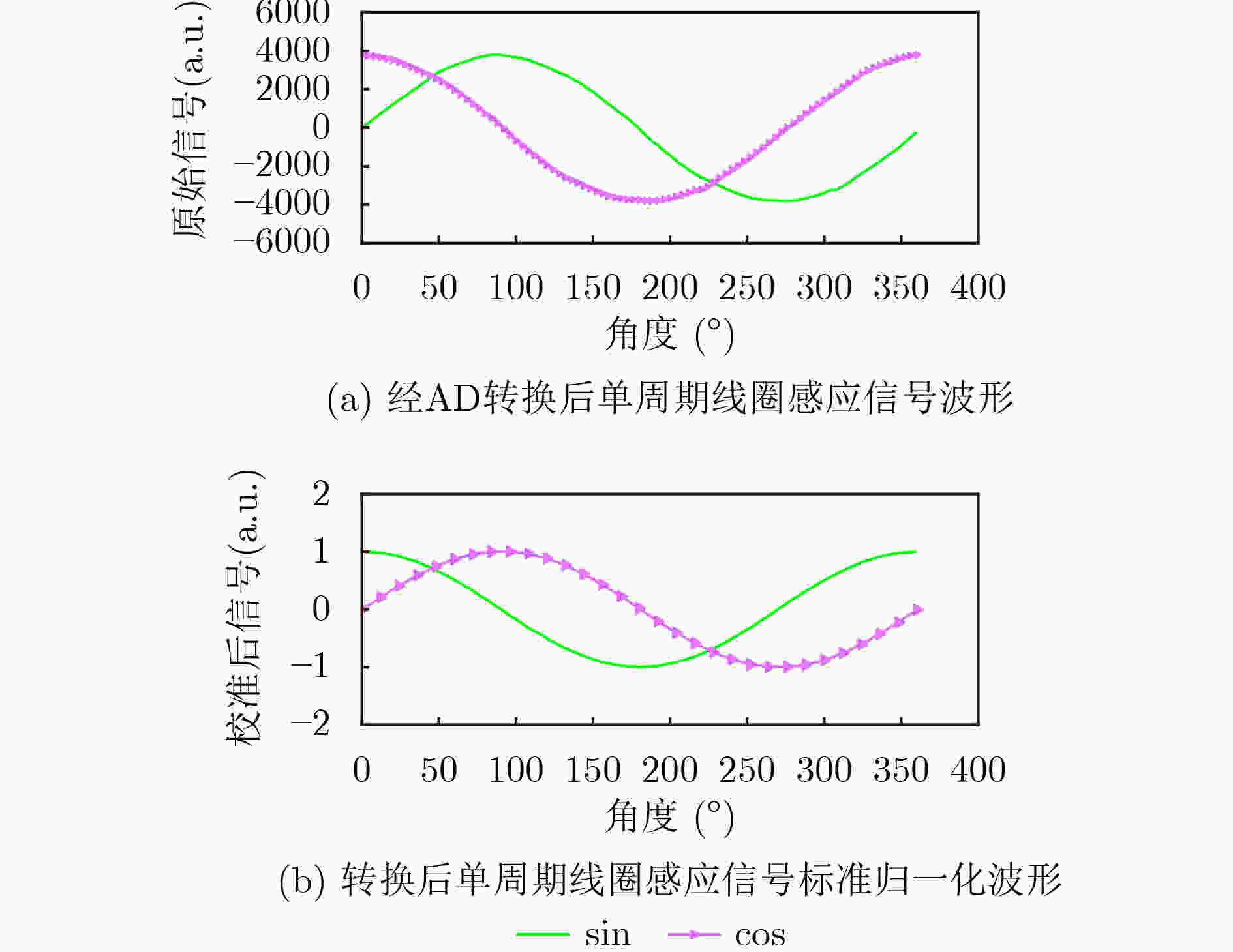

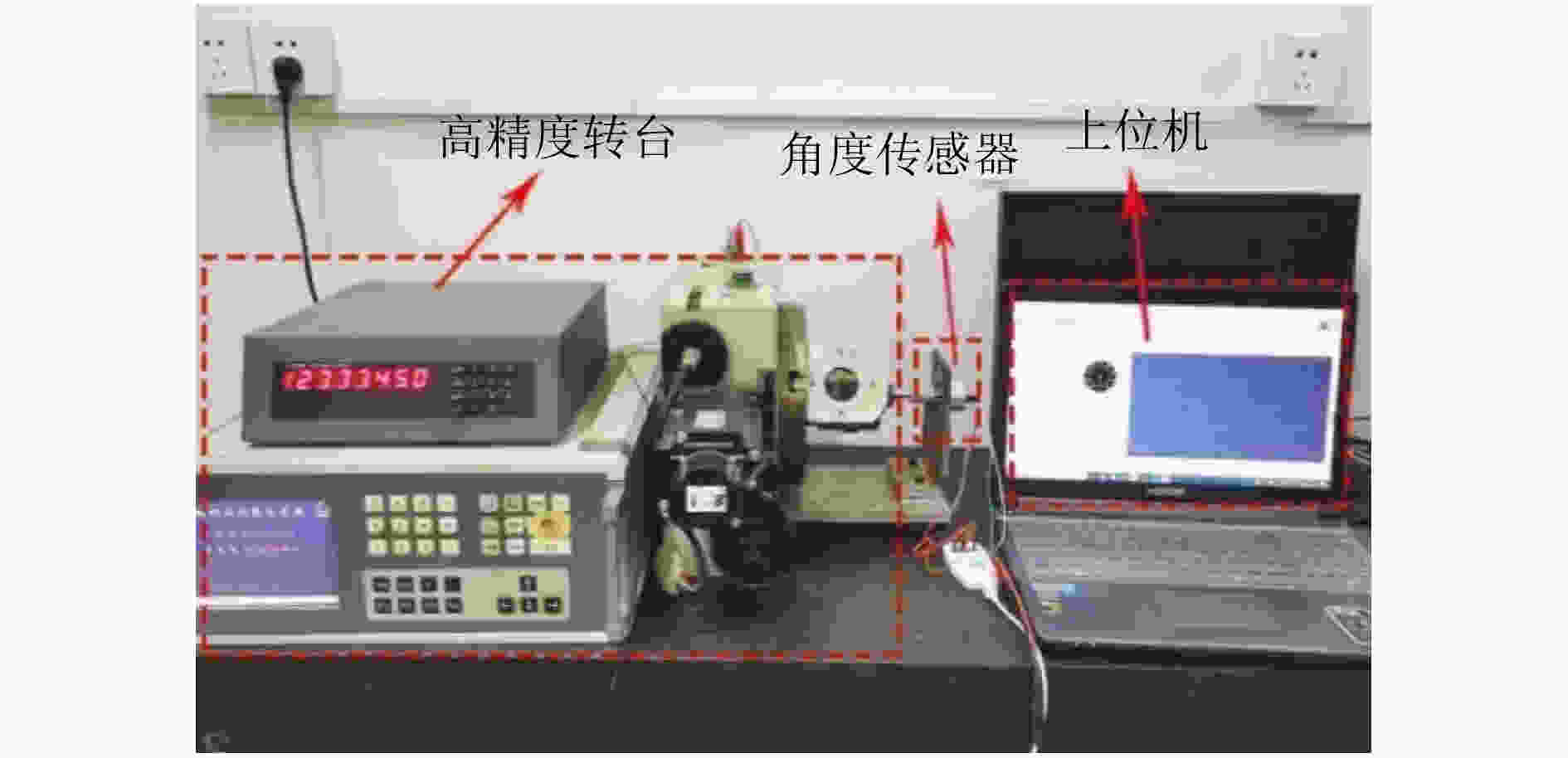

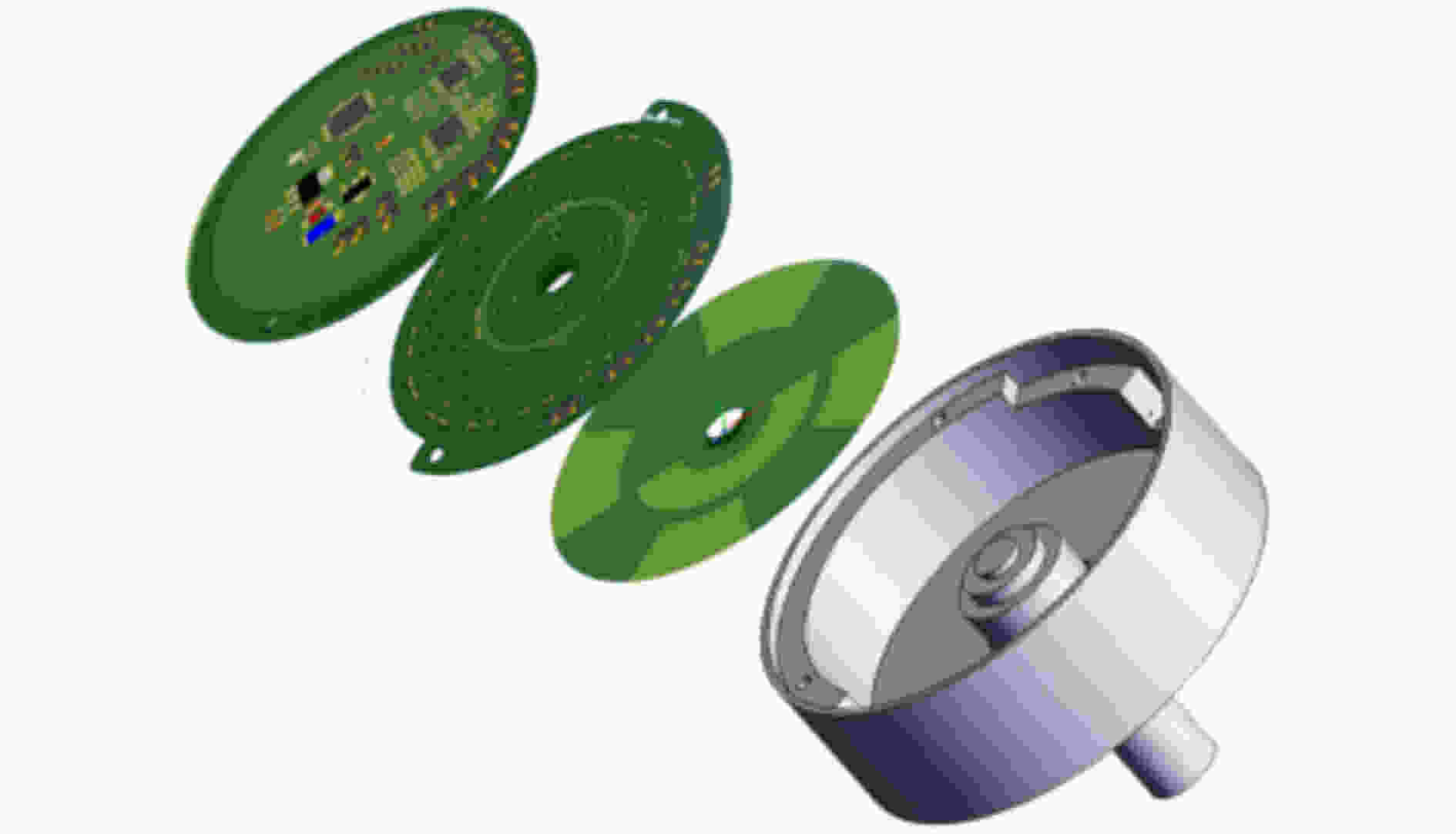

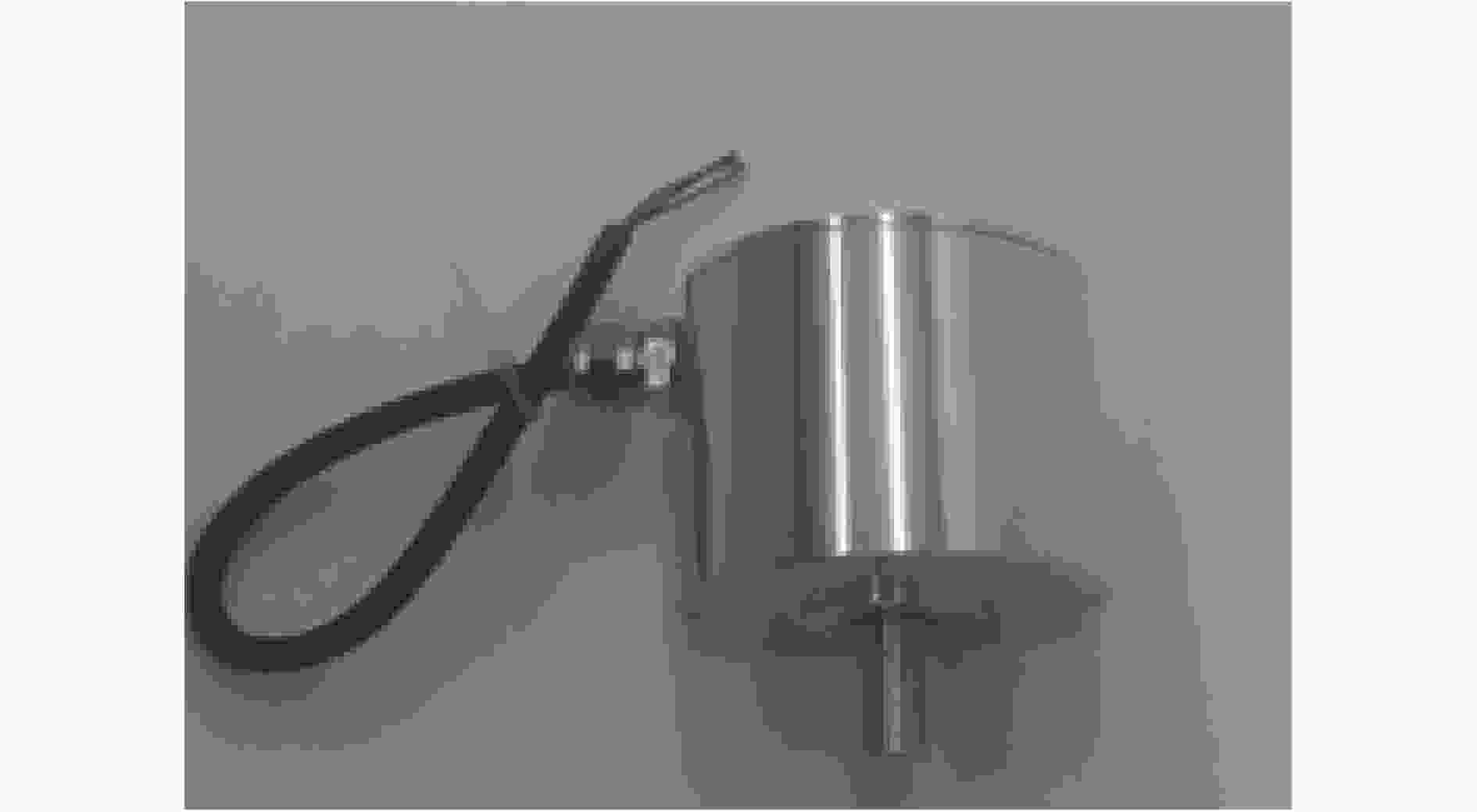

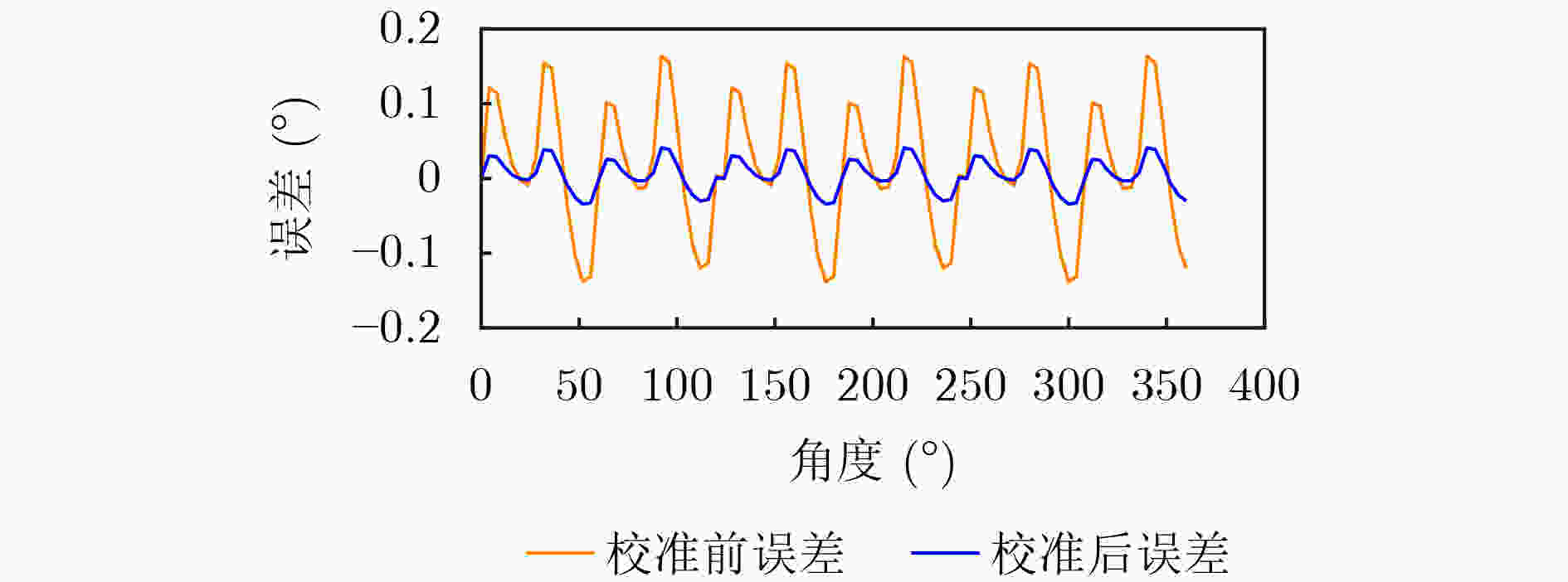

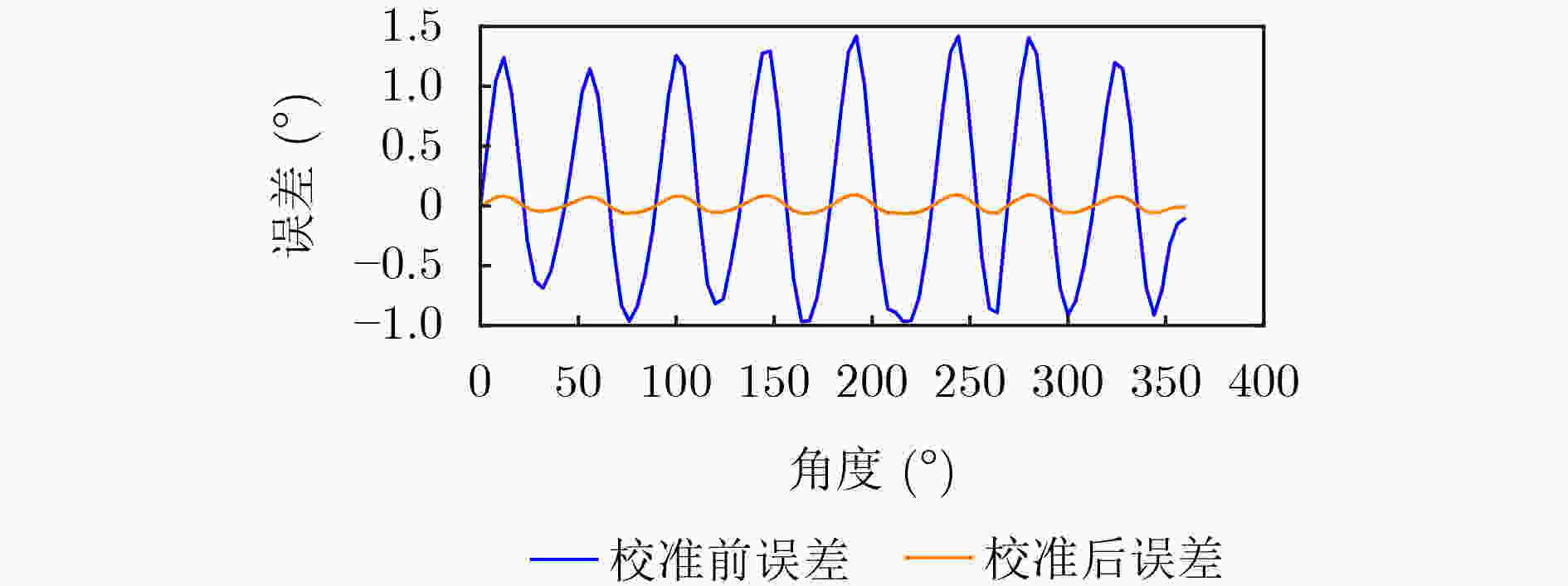

摘要: 角度传感器作为电机的核心定位部件,对电机的定位精度有重要影响。该文设计了一种双极电感式绝对角度传感器,该传感器通过周期性改变线圈中感应电压的大小来测量角度,敏感结构主要包括转子和定子,可实现与电机主轴的一体化。其中转子由内外单周期、多周期扇形铜箔组成,形成双极布局,定子由激励线圈、接收线圈以及后续处理电路组成。定子中的两组接收线圈,一组线圈由8个回路组成,对应为外沿多周期扇形铜箔,另一组由2个回路组成,对应中心180°扇形(半圆形)铜箔,两组线圈相互独立,互不影响。当转子在接收线圈上方转动时,转子中产生的涡流会使相邻两个接收线圈感应电压呈周期性正余弦形式变化。8回路线圈测量精度高,但360°内会出现多个周期信号,无法实现绝对位置测量。而2回路线圈在360°范围感应出1个周期信号,通过2回路线圈为8回路线圈提供周期数鉴别,进而解决了绝对位置测量的问题。通过算法对正余弦信号进行识别解算,以高精度转台为基准对样机进行测试,结果表明,传感器测量误差可以达到0.04°,满足电机位置控制精度要求,验证了该方案的可行性。Abstract: As the core positioning component of the motor, the angle sensor has an important impact on the positioning accuracy of the motor. In this paper, a bipolar inductive absolute angle sensor is designed. The sensor measures the angle by periodically changing the induced voltage in the coil. The sensitive structure includes mainly the rotor and stator, the integration with the motor spindle can be realized. The rotor is composed of inner and outer single cycle and multi cycle fan-shaped copper foil in a bipolar layout, and the stator is composed of excitation coil, receiving coil and subsequent processing circuit. There are two groups of receiving coils in the stator. One group of coils is composed of 8 loops, corresponding to multi cycle sector copper foil on the outer edge, and the other group is composed of 2 loops, corresponding to 180° sector (semicircular) copper foil on the center. The two groups of coils are independent of each other and do not affect each other. When the rotor rotates above the receiving coil, the eddy current generated in the rotor will make the induced voltage of two adjacent receiving coils change in the form of periodic sine and cosine. The measurement accuracy of 8-loop coil is high, but multiple periodic signals will appear within 360°, so the absolute position measurement can not be realized. By measuring the number of cycles of the coil, the problem is solved by identifying the number of cycles of the coil 1 and the number of cycles of the coil 2. The sine and cosine signals are identified and solved by the algorithm, and the prototype is tested based on the high-precision turntable. The results show that the measurement error of the sensor can reach 0.04°, which meets the requirements of motor position control accuracy, and verifies the feasibility of the scheme.

-

Key words:

- Motor positioning /

- Bipolar /

- Inductive angle sensor /

- Electromagnetic induction /

- Absolute position

-

表 1 Maxwell仿真条件和参数

仿真条件 参数值 激励源 幅值为5 V,频率为4 MHz的高频交流电压信号 线圈材质 铜 转子结构材质 铜 求解器 Magnetic transient 仿真步长 0.006 μs 仿真时间 22.362 μs -

[1] 刘焱, 王烨. 位移传感器的技术发展现状与发展趋势[J]. 自动化技术与应用, 2013, 32(6): 76–80,101.LIU Yan and WANG Ye. Present status and thrend of technical development of displacement sensor[J]. Techniques of Automation and Applications, 2013, 32(6): 76–80,101. [2] CHEN Yuwen, CHANDRA M, and LO C Y. Calibrations on shear angle detections in vertically stacked capacitive tactile sensors[J]. IEEE Sensors Journal, 2021, 21(23): 26269–26276. doi: 10.1109/Jsen.2021.3069075 [3] JING Gangshan, WAN Changhuang, and DAI Ran. Angle-based sensor network localization[J]. IEEE Transactions on Automatic Control, 2022, 67(2): 840–855. doi: 10.1109/Tac.2021.3061980 [4] 孙世政, 周清松, 何泽银. 嵌入式时栅角位移传感器短周期误差分析与补偿[J]. 仪器仪表学报, 2019, 40(4): 27–34. doi: 10.19650/j.cnki.cjsi.J1904608SUN Shizheng, ZHOU Qingsong, and HE Zeyin. Short period error analysis and compensation of embedded time grating angular displacement sensor[J]. Chinese Journal of Scientific Instrument, 2019, 40(4): 27–34. doi: 10.19650/j.cnki.cjsi.J1904608 [5] MERSHA B W, JANSEN D N, and MA Hongbin. Angle of attack prediction using recurrent neural networks in flight conditions with faulty sensors in the case of F-16 fighter jet[J/OL]. Complex & Intelligent Systems, 2021: 1–13. doi: 10.1007/s40747-021-00612-6. [6] KUMAR A S A and GEORGE B. A noncontact angle sensor based on eddy current technique[J]. IEEE Transactions on Instrumentation and Measurement, 2020, 69(4): 1275–1283. doi: 10.1109/TIM.2019.2908508 [7] ZHANG Chao, LI Zhipeng, CHEN Jie, et al. Design and research of a novel non-contact vertical inductive torque sensor[J]. Measurement, 2021, 177: 109252. doi: 10.1016/j.measurement.2021.10925 [8] TONDO F A, PORTO R W, VILLALOBOS L F S S M, et al. Eddy current probe identification and analysis[J]. IEEE Transactions on Instrumentation and Measurement, 2017, 66(8): 2166–2173. doi: 10.1109/TIM.2017.2684858 [9] 张波, 李杨, 陈小丽, 等. 用于伺服定位实验系统的高精度磁编码器设计与研制[J]. 实验技术与管理, 2021, 38(10): 183–192. doi: 10.16791/j.cnki.sjg.2021.10.034ZHANG Bo, LI Yang, CHEN Xiaoli, et al. Design and development of high precision magnetic encoder for servo positioning experiment system[J]. Experimental Technology and Management, 2021, 38(10): 183–192. doi: 10.16791/j.cnki.sjg.2021.10.034 [10] TANG Qifu, PENG Donglin, WU Liang, et al. An inductive angular displacement sensor based on planar coil and contrate rotor[J]. IEEE Sensors Journal, 2015, 15(7): 3947–3954. doi: 10.1109/JSEN.2015.2404349 [11] 翁道纛, 汤其富, 彭东林, 等. 一种互补耦合型电磁感应式直线位移传感器的研究[J]. 传感技术学报, 2019, 32(7): 996–1002. doi: 10.3969/j.issn.1004-1699.2019.07.007WENG Daodao, TANG Qifu, PENG Donglin, et al. Research on a linear inductive displacement sensor with complementary coupling structure[J]. Chinese Journal of Sensors and Actuators, 2019, 32(7): 996–1002. doi: 10.3969/j.issn.1004-1699.2019.07.007 [12] 李哲, 吴正国, 夏立, 等. 任意负载条件下动态电压恢复器的复合谐振控制策略[J]. 中国电机工程学报, 2013, 33(25): 130–138. doi: 10.13334/j.0258-8013.pcsee.2013.25.002LI Zhe, WU Zhengguo, XIA Li, et al. Compound resonant control for dynamic voltage restorers under arbitrary load conditions[J]. Proceedings of the CSEE, 2013, 33(25): 130–138. doi: 10.13334/j.0258-8013.pcsee.2013.25.002 [13] HRISTOFOROU E, DIMITROPOULOS P D, and PETROU J. A new position sensor based on the MDL technique[J]. Sensors and Actuators A:Physical, 2006, 132(1): 112–121. doi: 10.1016/j.sna.2006.04.015 [14] ANANDAN N, MUPPALA A V, and GEORGE B. A flexible, planar-coil-based sensor for through-shaft angle sensing[J]. IEEE Sensors Journal, 2018, 18(24): 10217–10224. doi: 10.1109/JSEN.2018.2874065 [15] WANG Lefan, MEYDAN T, WILLIAMS P, et al. A proposed optical-based sensor for assessment of hand movement[C]. 2015 IEEE Sensors, Busan, Korea (South), 2015: 1–4. [16] JIANG Cuili, TIAN Zhihui, and YU Wenjiao. Displacement measurement technology of nano grating sensor based on HHT algorithm[J]. Microelectronics Journal, 2021, 109: 104986. doi: 10.1016/J.MEJO.2020.104986 -

下载:

下载:

下载:

下载: