Experimental Study and Theoretical Model for Increasing the Current Density of Thermionic Cathodes through Active Impregnant Substance

-

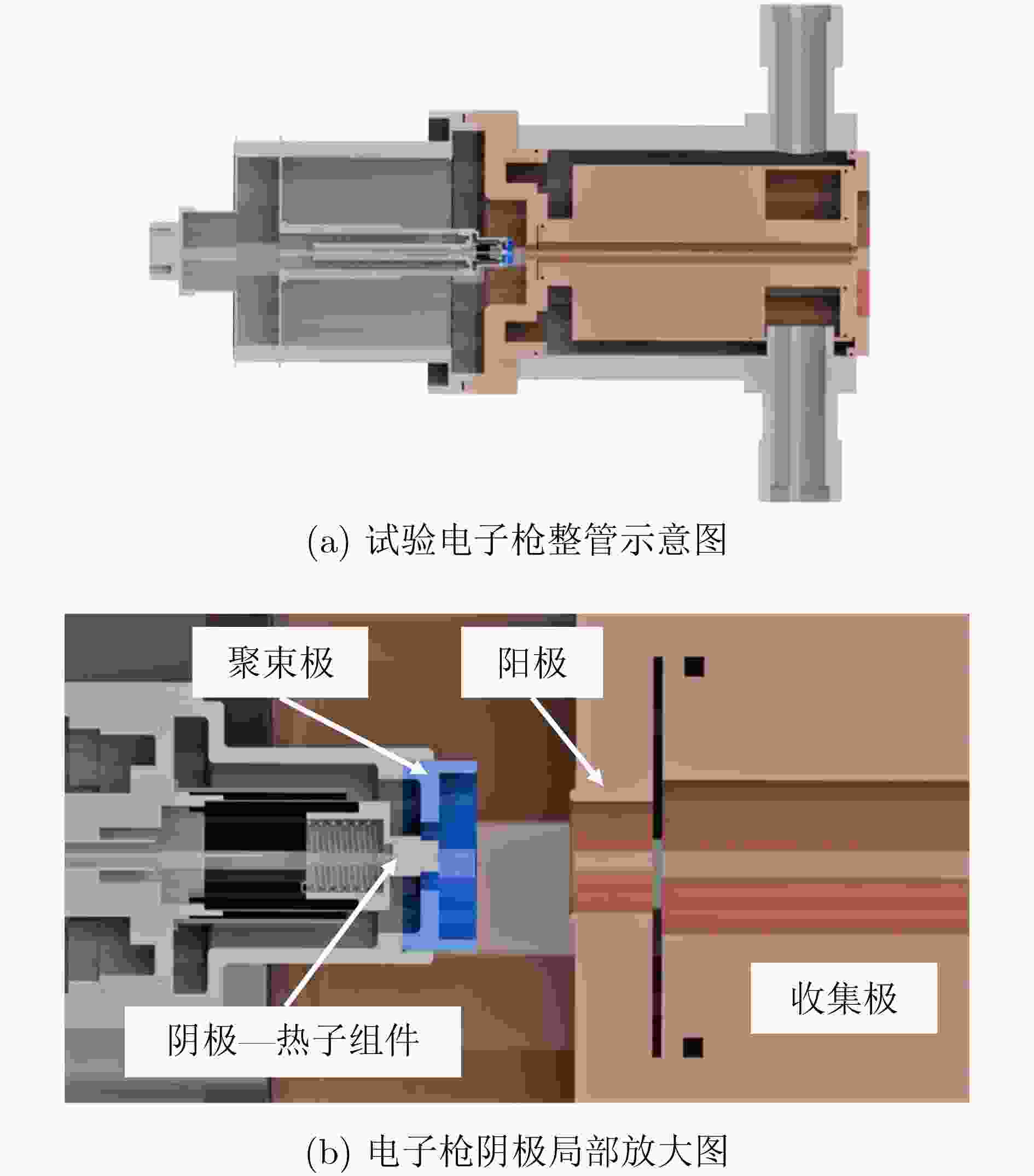

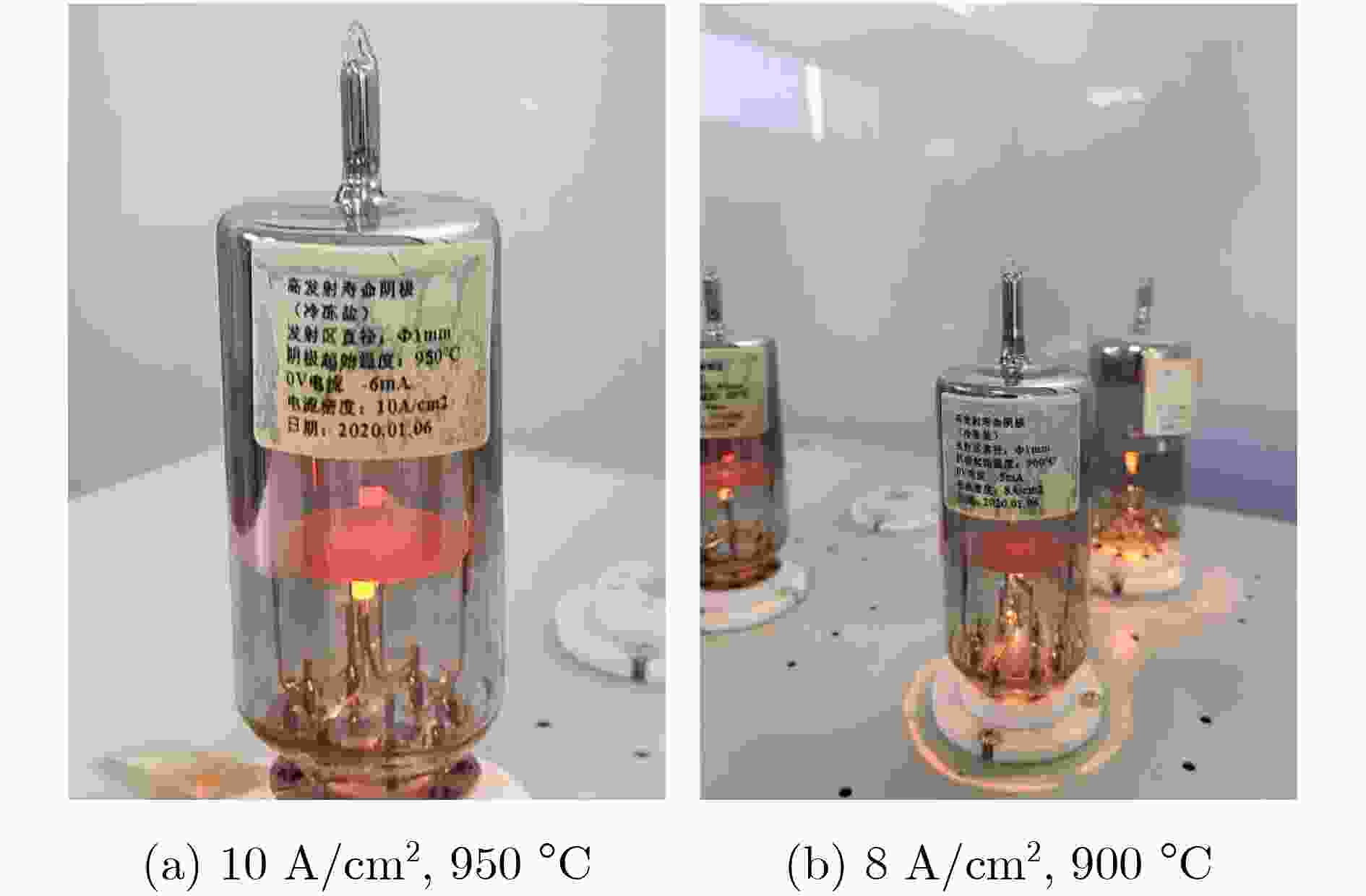

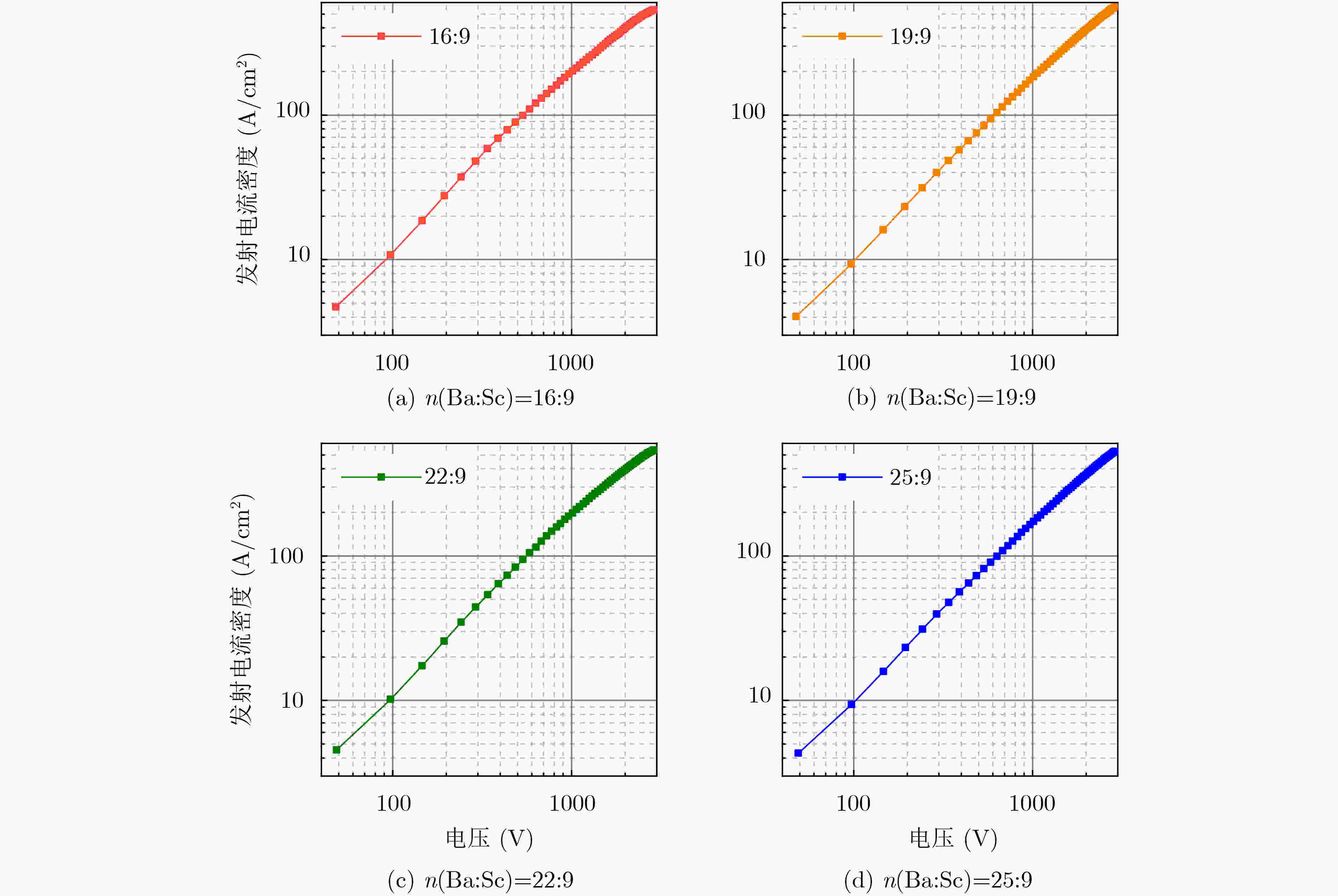

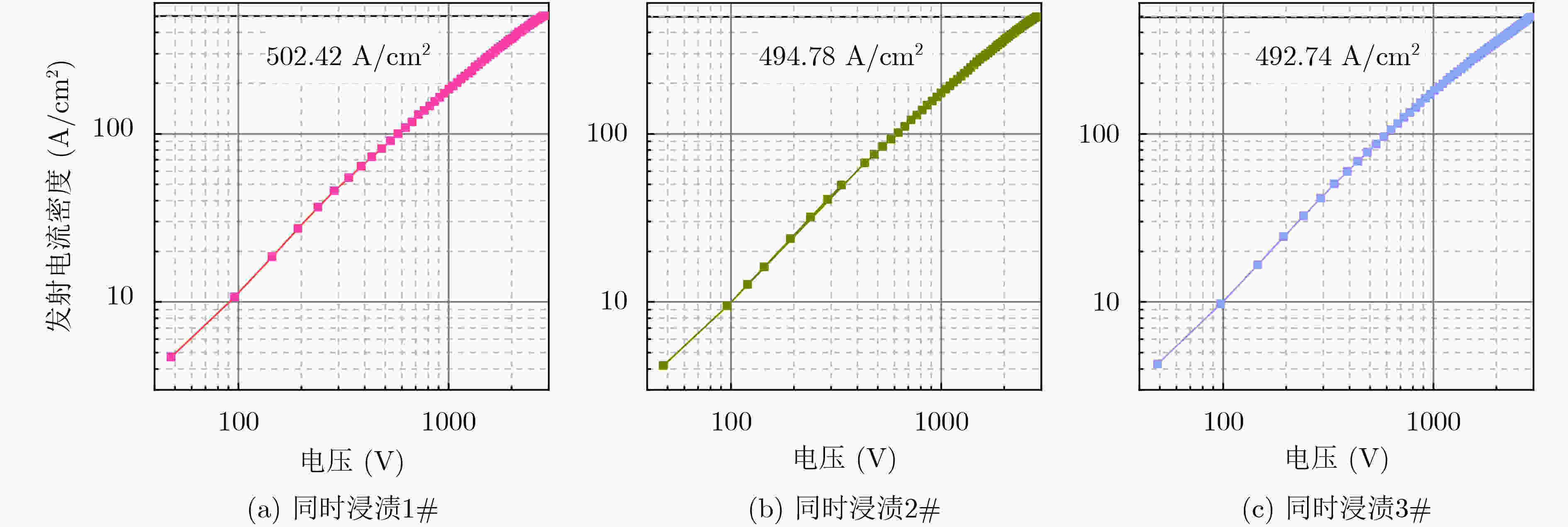

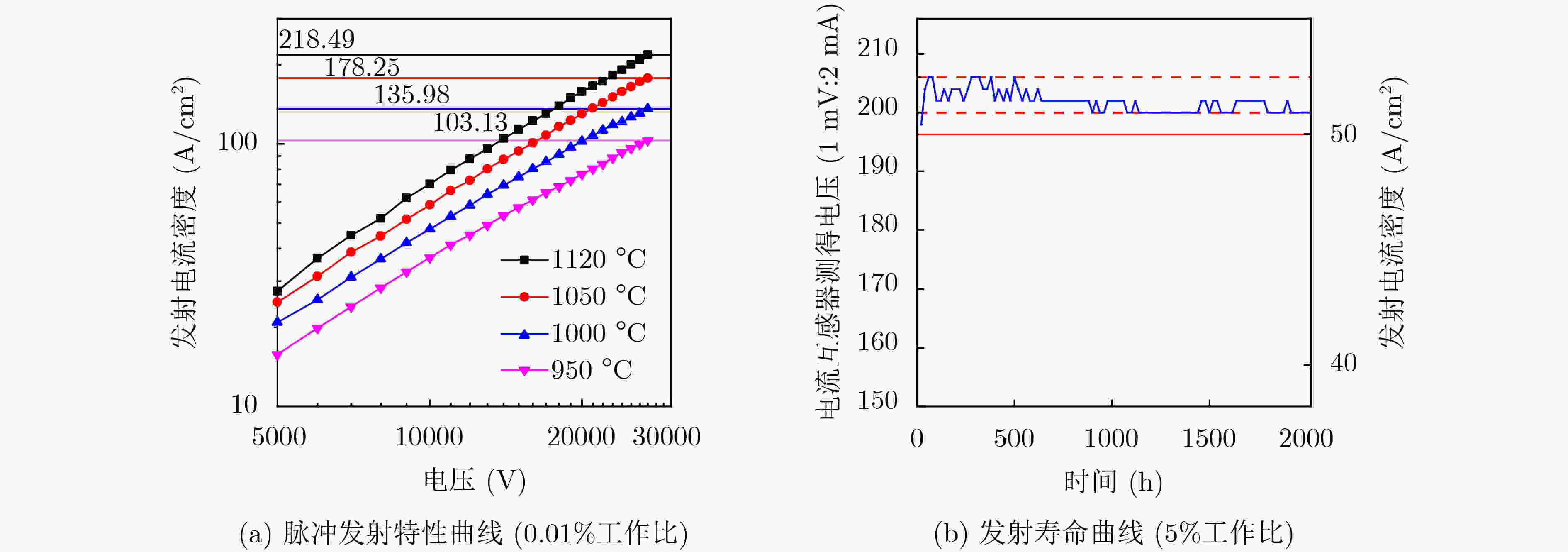

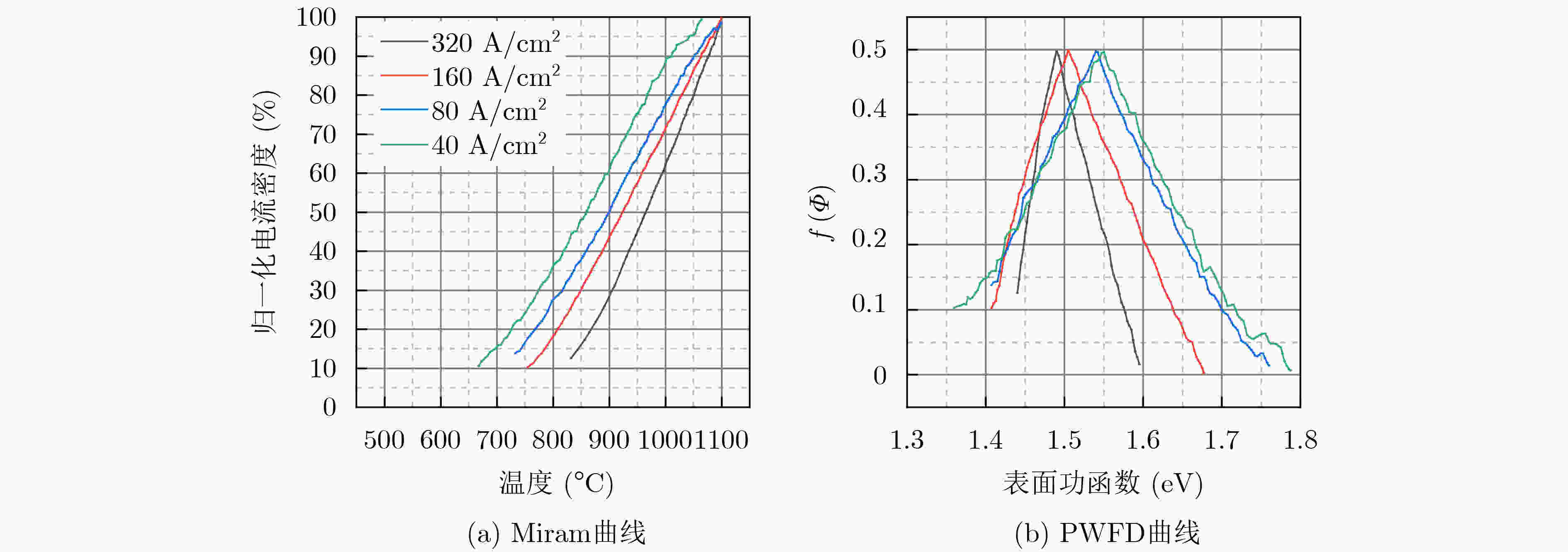

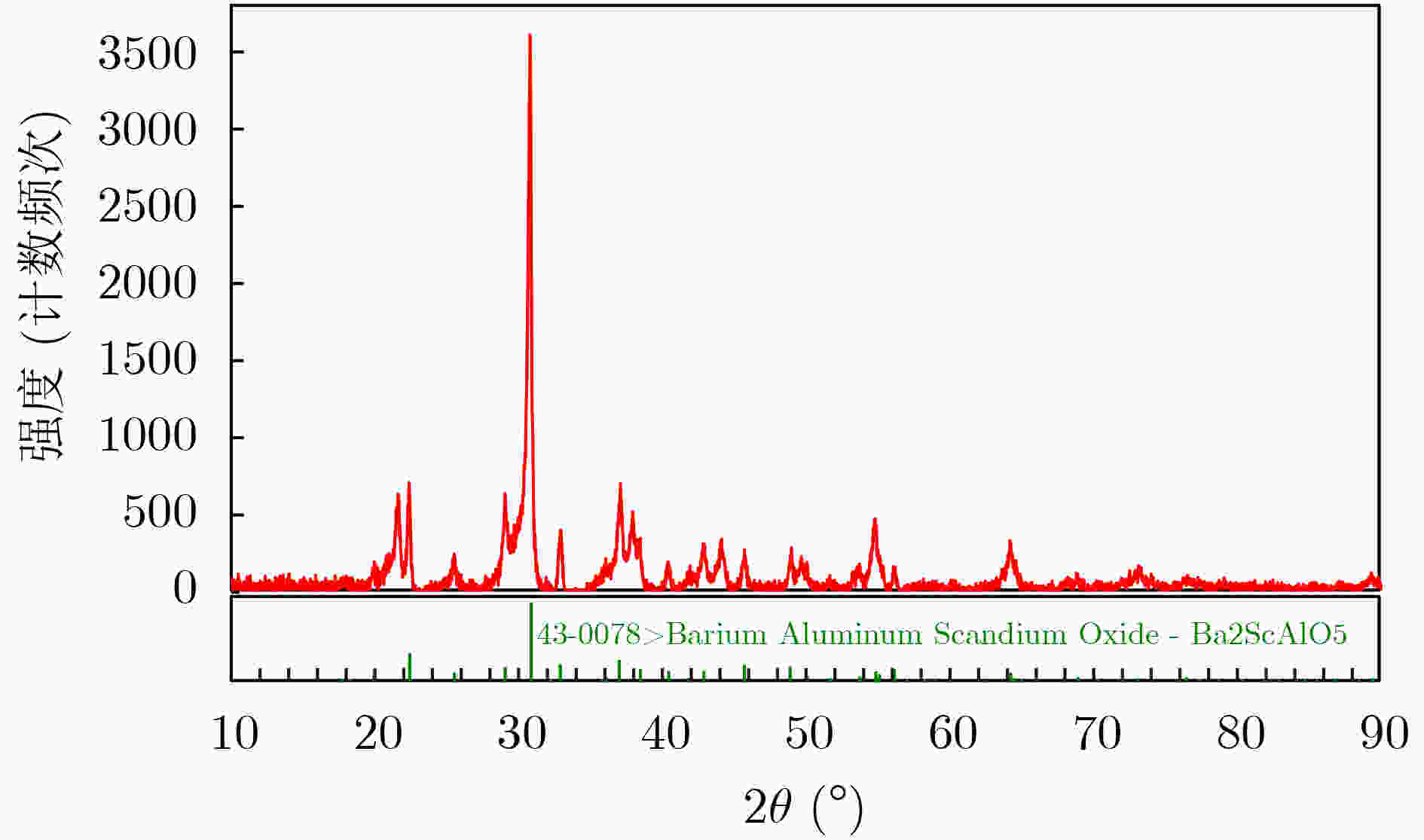

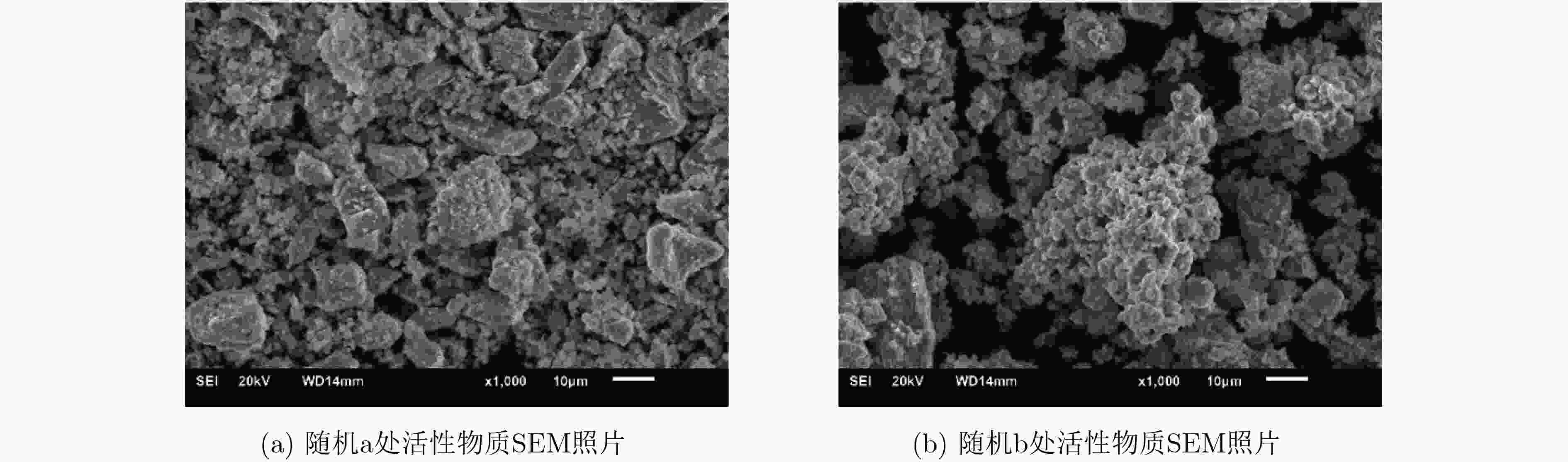

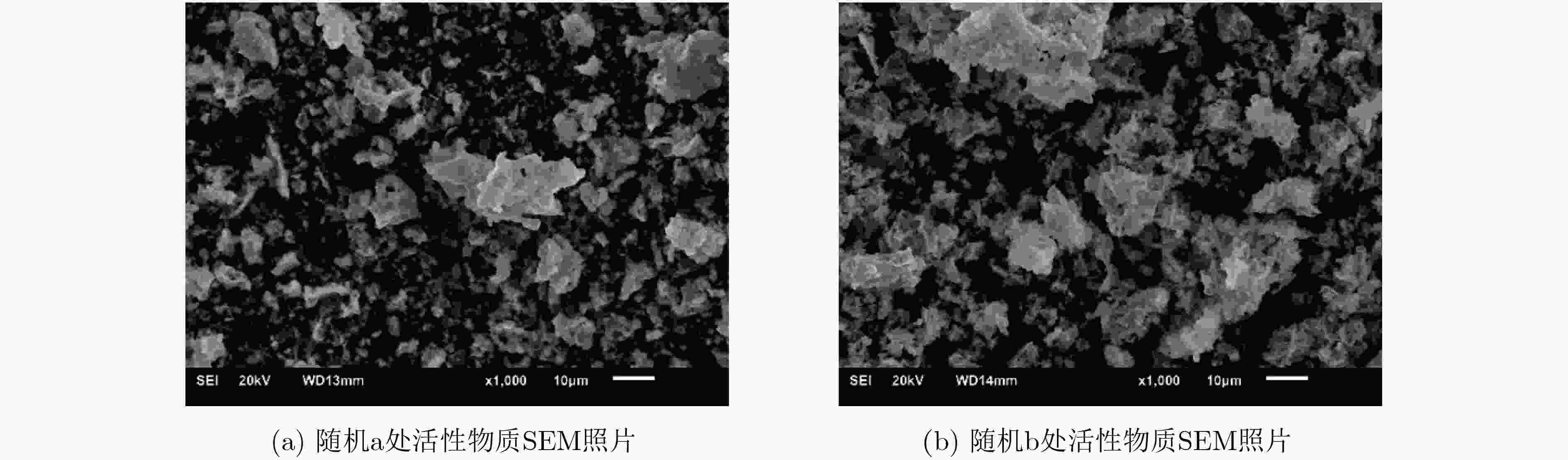

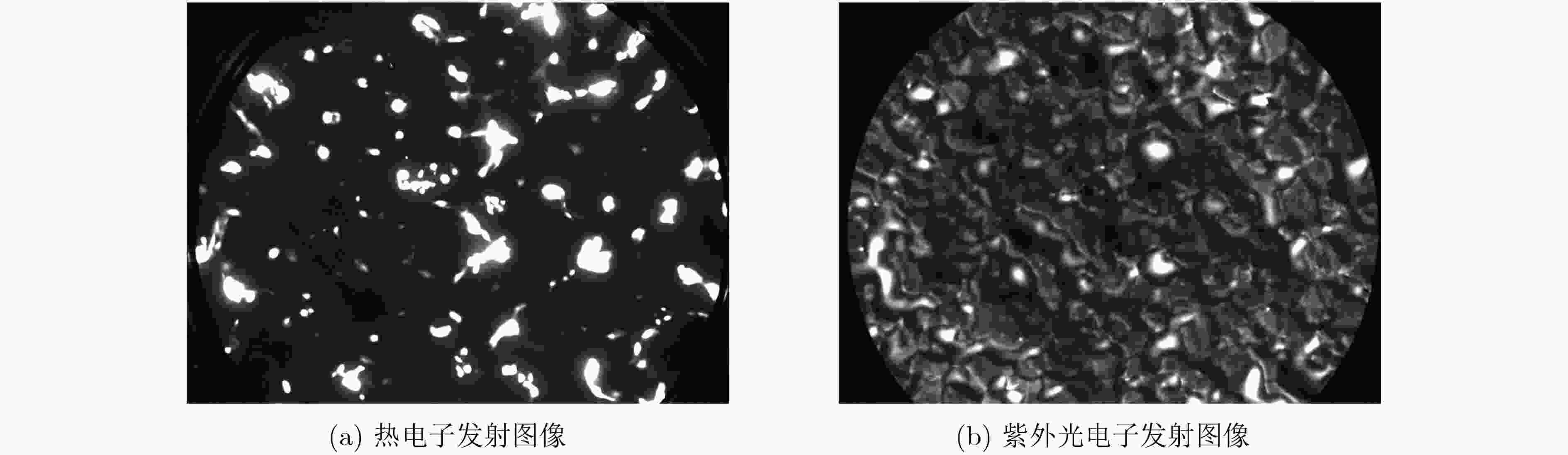

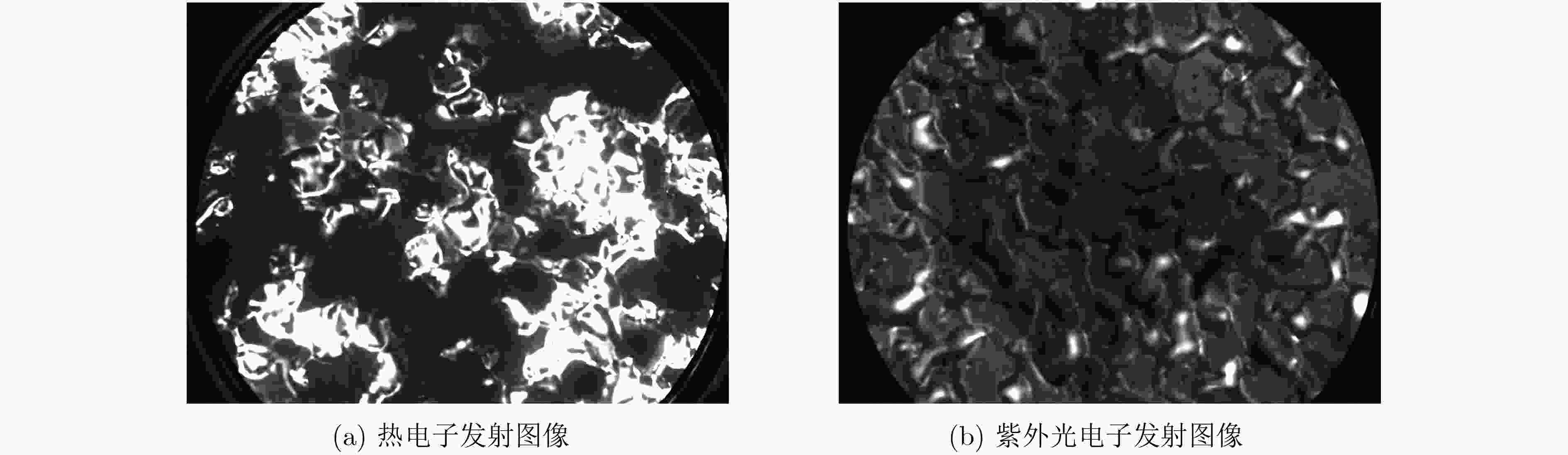

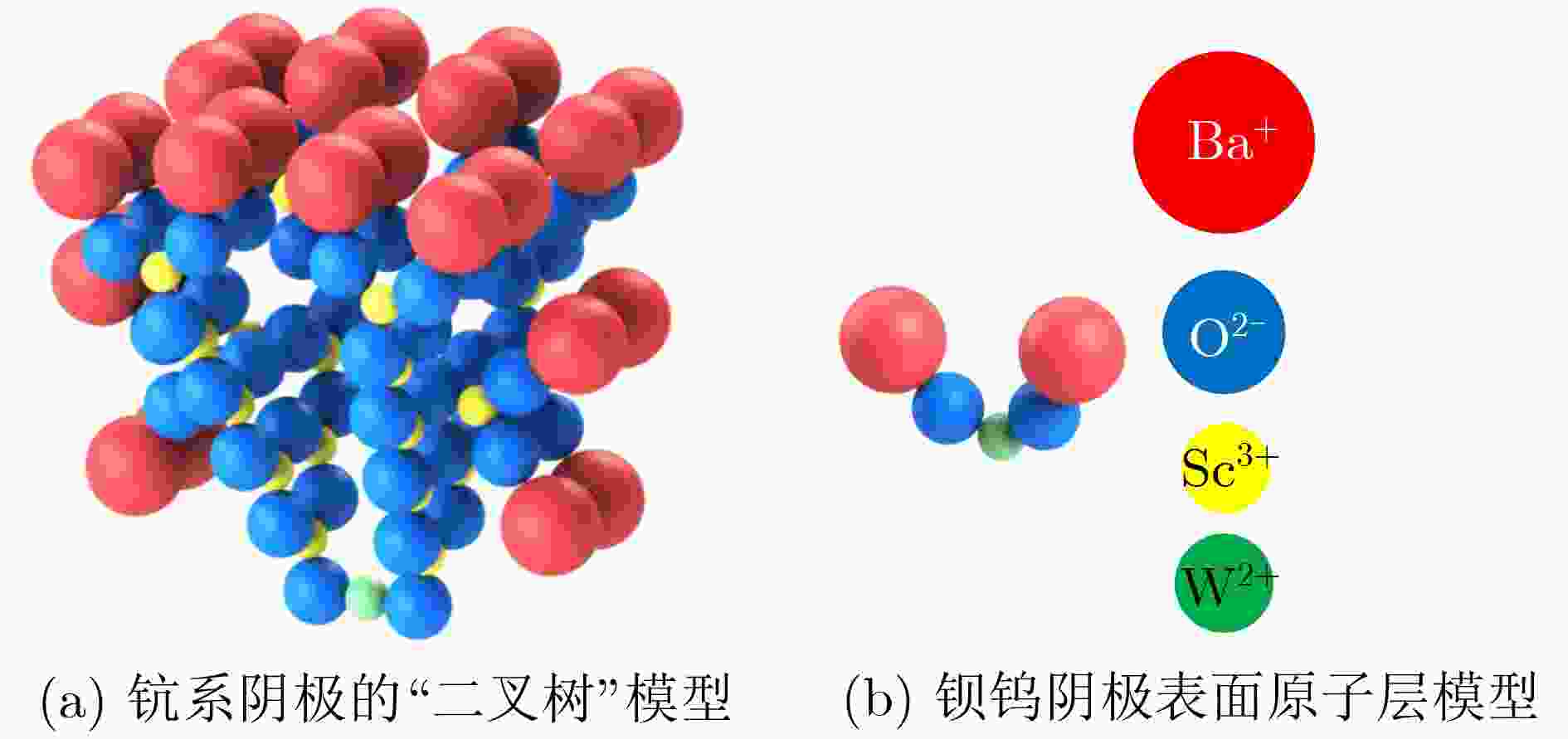

摘要: 通过发展新的活性物质成分系统及其制备方法以提升钪系阴极的电子发射性能,是当今热阴极特别是大电流密度阴极领域的研究重点。该文提出一种由多元金属氧化物构成的新型高活性浸渍物质,显著提升了钪在阴极中的添加比例,大幅提高了阴极的发射电流密度。将冷冻干燥法应用到该活性物质前驱体的制备过程中,有效解决了传统固相合成方法在机械式破碎、研磨和混合等工序中存在的不可控、不均匀等问题。采用了新的成分系统与新的制备方法制得活性物质的阴极,在真空二极管测试和电子枪测试中分别取得了超过500 A/cm2和218.5 A/cm2的脉冲发射电流密度。在二极管直流测试条件下,阴极的寿命测试进行了10500 h后仍未出现发射电流下降的现象;而在电子枪中的大工作比(5%)脉冲测试条件下,阴极在工作了2010 h后仍维持了超过50 A/cm2的较大发射电流密度。借助深紫外—光/热发射电子显微镜(DUV-PEEM/TEEM)分析发现,相较传统的钪系阴极,新制备的大电流密度阴极表面的热电子发射位点数量增加,微区发射面积显著增大。最后,提出一种“二叉树”发射模型,以期阐释钪系阴极采用新活性物质后获得高发射特性的物理机制。Abstract: Developing new active substance composition system and its preparation method to enhance scandate cathode’s emission property is a hotspot in the research field of thermionic cathode especially high-emission cathode. A novel highly active impregnant substance consisting of polymetallic oxide which apparently increases scandium’s appending proportion and greatly enhances cathode’s emission current density is put forward in this paper. Freeze-drying method is applied into preparation of the active substance’s precursor and effectively solves the problem of inhomogeneity and uncontrollability in the mechanical crushing, grinding and mixing procedures of conventional solid-phase synthesis routine. Cathode which adopted novel composition system and substance acquired by new preparation routine reaches a pulse emission current density of above 500 A/cm2 under close-spaced diode configuration and 218.5 A/cm2 in an electron gun. Under the DC diode experimental configuration, the cathodes’ emission lifetime test has endured for 10500 hours with no emission current drop; while in the electron gun with a pulse drive of heavy duty cycle (5%), the cathode maintains a big workload of more than 50 A/cm2 after having worked for 2010 hours. Via Deep UltraViolet laser-Photo Emission and Thermal Emission Electron Microscopy (DUV-PEEM/TEEM) analyzation, the phenomenon ofthermionic emission points’ amount increases and emitting micro-area expands on the newly prepared high-emission cathode’s surface is observed. Finally, a ‘binary tree’ emission model is brought up, hoping to explain the physical mechanism of scandate cathode’s high emission character with new active substance.

-

表 2 机械混合法与冷冻干燥法制得活性物质的元素分布情况(%)

方法 机械混合法 冷冻干燥法 位置 a b a b 元素 wt at wt at wt at wt at OK 18.17 52.56 18.84 56.51 17.37 52.78 18.08 54.07 AlK 01.67 2.86 01.86 03.30 05.11 09.20 05.13 09.08 SrK 08.51 4.49 08.15 04.46 05.78 03.21 05.32 02.91 CaK 02.69 3.11 02.66 03.19 03.78 04.59 03.36 04.00 ScK 19.85 20.43 11.96 12.77 08.52 09.20 08.67 09.23 BaL 49.11 16.55 56.53 19.75 59.44 21.03 59.44 20.72 表 1 计算阴极表面功函数分布情况

发射负载 (A/cm2) 320 160 80 40 功函数峰值(eV) 1.490 1.505 1.540 1.550 肖特基eΔφ/eV 0.103 0.077 0.059 0.044 零场eφ/eV 1.593 1.582 1.599 1.594 半峰宽度 (eV) 0.089 0.151 0.190 0.194 -

[1] 沈春英, 丘泰, 李晓云. 高性能浸渍型阴极材料研究进展[J]. 材料导报, 2005, 19(3): 25–27. doi: 10.3321/j.issn:1005-023X.2005.03.008SHEN Chunying, QIU Tai, and LI Xiaoyun. Advances in dispenser cathodes materials with high properties[J]. Materials Reports, 2005, 19(3): 25–27. doi: 10.3321/j.issn:1005-023X.2005.03.008 [2] VANCIL B, OHLINGER W L, GREEN M C, et al. New findings on powder synthesis for scandate cathode matrices[J]. IEEE Transactions on Electron Devices, 2018, 65(6): 2077–2082. doi: 10.1109/TED.2018.2820606 [3] YIN Shengyin, ZHANG Zhaochuan, PENG Zhen, et al. A new impregnated dispenser cathode[J]. IEEE Transactions on Electron Devices, 2013, 60(12): 4258–4262. doi: 10.1109/TED.2013.2287729 [4] 吴祖璇, 张邦胜, 王芳, 等. 超细粉体制备技术研究[J]. 中国资源综合利用, 2020, 38(12): 108–112. doi: 10.3969/j.issn.1008-9500.2020.12.034WU Zuxuan, ZHANG Bangsheng, WANG Fang, et al. Research on preparation technology of ultrafine powder[J]. China Resources Comprehensive Utilization, 2020, 38(12): 108–112. doi: 10.3969/j.issn.1008-9500.2020.12.034 [5] ZHENG Qiang, SHANG Yafen, CAO Yutao, et al. A comparative study of the co-precipitate synthesis of barium-calcium-aluminates impregnants for dispenser cathodes by using different precipitants[J]. Ceramics International, 2019, 45(9): 11495–11500. doi: 10.1016/j.ceramint.2019.03.018 [6] 李娜, 于志强, 高玉娟. M型扩散阴极用新型含锶低蒸散发射活性材料[J]. 真空科学与技术学报, 2020, 40(12): 1202–1207. doi: 10.13922/j.cnki.cjovst.2020.12.15LI Na, YU Zhiqiang, and GAO Yujuan. Thermal evaporation/emission properties of Sr-doped emission active coatings of m-type cathode[J]. Chinese Journal of Vacuum Science and Technology, 2020, 40(12): 1202–1207. doi: 10.13922/j.cnki.cjovst.2020.12.15 [7] 方健. 室温固相法制备铝酸盐研究[D]. [硕士论文], 电子科技大学, 2019.FANG Jian. Study on the room-temperature solid-state reaction method for preparing aluminates for impregnant cathodes[D]. [Master dissertation], University of Electronic Science and Technology of China, 2019. [8] 崔云涛, 王金淑, 刘伟, 等. 含钪扩散阴极用铝酸盐的制备及发射性能研究[J]. 无机材料学报, 2012, 27(5): 480–484. doi: 10.3724/SP.J.1077.2012.00480CUI Yuntao, WANG Jinshu, LIU Wei, et al. Fabrication of aluminate for scandia doped dispenser cathode and emission property[J]. Journal of Inorganic Materials, 2012, 27(5): 480–484. doi: 10.3724/SP.J.1077.2012.00480 [9] PALMERO P, ESNOUF C, MONTANARO L, et al. Influence of the co-precipitation temperature on phase evolution in yttrium-aluminium oxide materials[J]. Journal of the European Ceramic Society, 2005, 25(9): 1565–1573. doi: 10.1016/j.jeurceramsoc.2004.05.027 [10] VALENZUELA R, FUENTES M C, PARRA C, et al. Influence of stirring velocity on the synthesis of magnetite nanoparticles (Fe3O4) by the co-precipitation method[J]. Journal of Alloys and Compounds, 2009, 488(1): 227–231. doi: 10.1016/j.jallcom.2009.08.087 [11] RAHMANI M, MIRZAEE O, TAJALLY M, et al. A comparative study of synthesis and spark plasma sintering of YAG nano powders by different co-precipitation methods[J]. Ceramics International, 2018, 44(9): 10035–10046. doi: 10.1016/j.ceramint.2018.02.148 [12] LI J G, IKEGAMI T, LEE J H, et al. Co-precipitation synthesis and sintering of yttrium aluminum garnet (YAG) powders: The effect of precipitant[J]. Journal of the European Ceramic Society, 2000, 20(14/15): 2395–2405. doi: 10.1016/S0955-2219(00)00116-3 [13] MARLOT C, BARRAUD E, LE GALLET S, et al. Synthesis of YAG nanopowder by the co-precipitation method: Influence of pH and study of the reaction mechanisms[J]. Journal of Solid State Chemistry, 2012, 191: 114–120. doi: 10.1016/j.jssc.2012.02.063 [14] BHATTA S, JANEZIC T S, and RATTI C. Freeze-drying of plant-based foods[J]. Foods, 2020, 9(1): 87. doi: 10.3390/foods9010087 [15] VISHALI D A, MONISHA J, SIVAKAMASUNDARI S K, et al. Spray freeze drying: Emerging applications in drug delivery[J]. Journal of Controlled Release, 2019, 300: 93–101. doi: 10.1016/j.jconrel.2019.02.044 [16] CASTALDO R, LAMA G C, APREA P, et al. Effect of the oxidation degree on self-assembly, adsorption and barrier properties of nano-graphene[J]. Microporous and Mesoporous Materials, 2018, 260: 102–115. doi: 10.1016/j.micromeso.2017.10.026 [17] CATTELINO M and MIRAM G. Predicting cathode life expectancy and emission quality from PWFD measurements[J]. Applied Surface Science, 1997, 111: 90–95. doi: 10.1016/S0169-4332(96)00718-0 [18] 朱木易, 高玉娟, 邵文生, 等. 对钪系阴极实际功函数分布偏移现象的探讨[J]. 真空电子技术, 2014(4): 29–31. doi: 10.16540/j.cnki.cn11-2485/tn.2014.04.013ZHU Muyi, GAO Yujuan, SHAO Wensheng, et al. A study of excursion of practical work function distribution of Sc-Type Cathodes[J]. Vacuum Electronics, 2014(4): 29–31. doi: 10.16540/j.cnki.cn11-2485/tn.2014.04.013 [19] MAKAROV A P, BERSNEVA E U, ZEMCHIKHIN E M, et al. Emission properties, microstructure and surface composition of scandate impregnated cathodes with tungsten and a tungsten-rhenium matrix[C]. The 10th International Vacuum Electron Sources Conference, St. Petersburg, Russia, 2014: 1–2. doi: 10.1109/IVESC.2014.6892027. [20] SHANG Yafen, LUO Fengting, FANG Jian, et al. The effect of scandia doping on the structure and electron emission capacity of the 512 aluminate[C]. 2018 IEEE International Vacuum Electronics Conference, Monterey, USA, 2018: 235–236. doi: 10.1109/IVEC.2018.8391634. [21] 阴生毅, 任峰, 卢志鹏, 等. 覆膜浸渍扩散阴极表面微区电子发射像研究[J]. 电子与信息学报, 2018, 40(10): 2535–2540. doi: 10.11999/JEIT171000YIN Shengyi, REN Feng, LU Zhipeng, et al. Study on electron emission phenomenon of the surface micro area of coated impregnated dispenser cathode[J]. Journal of Electronics &Information Technology, 2018, 40(10): 2535–2540. doi: 10.11999/JEIT171000 [22] WANG Jinshu, CUI Yuntao, LIU Wei, et al. A study of scandia-doped-impregnated cathode fabricated by spray drying method[J]. IEEE Transactions on Electron Devices, 2015, 62(5): 1635–1640. doi: 10.1109/TED.2015.2412153 [23] WANG Jinshu, LI Lili, LIU Wei, et al. Sc2O3–W matrix impregnated cathode with spherical grains[J]. Journal of Physics and Chemistry of Solids, 2008, 69(8): 2103–2108. doi: 10.1016/j.jpcs.2008.03.013 [24] 王金淑, 刘伟, 崔云涛, 等. 氧化钪混合钨基扩散型阴极表面结构的研究[J]. 稀有金属材料与工程, 2009, 38(12): 2191–2194. doi: 10.3321/j.issn:1002-185X.2009.12.027WANG Jinshu, LIU Wei, CUI Yuntao, et al. Study on surface structure of scandia mixed tungsten matrix impregnated dispenser cathode[J]. Rare Metal Materials and Engineering, 2009, 38(12): 2191–2194. doi: 10.3321/j.issn:1002-185X.2009.12.027 [25] 王金淑, 崔云涛, 刘伟, 等. 钪钨基压制型阴极的制备及性能研究[J]. 功能材料信息, 2015, 12(2): 7–11.WANG Jinshu, CUI Yuntao, LIU Wei, et al. Preparation and emission property of scandia doped tungsten pressed cathode[J]. Functional Materials Information, 2015, 12(2): 7–11. [26] 卢志鹏, 阴生毅, 任峰, 等. 一种新型覆膜含钪阴极的研究[C]. 中国电子学会真空电子学分会第二十一届学术年会论文集, 平凉, 2018: 5. [27] 彭真, 阴生毅, 郑强, 等. 脉冲激光沉积技术制备的钪型阴极的发射性能[J]. 电子与信息学报, 2014, 36(3): 754–757. doi: 10.3724/sp.j.1146.2013.00566PENG Zhen, YIN Shengyi, ZHENG Qiang, et al. Emission performance of scandate cathodes prepared by pulse laser deposition[J]. Journal of Electronics &Information Technology, 2014, 36(3): 754–757. doi: 10.3724/sp.j.1146.2013.00566 -

下载:

下载:

下载:

下载: