A Battery Internal-Short-Circuit Fault Diagnosis Method Combining Battery Phase Plane with Conformer-BiGRU Network

-

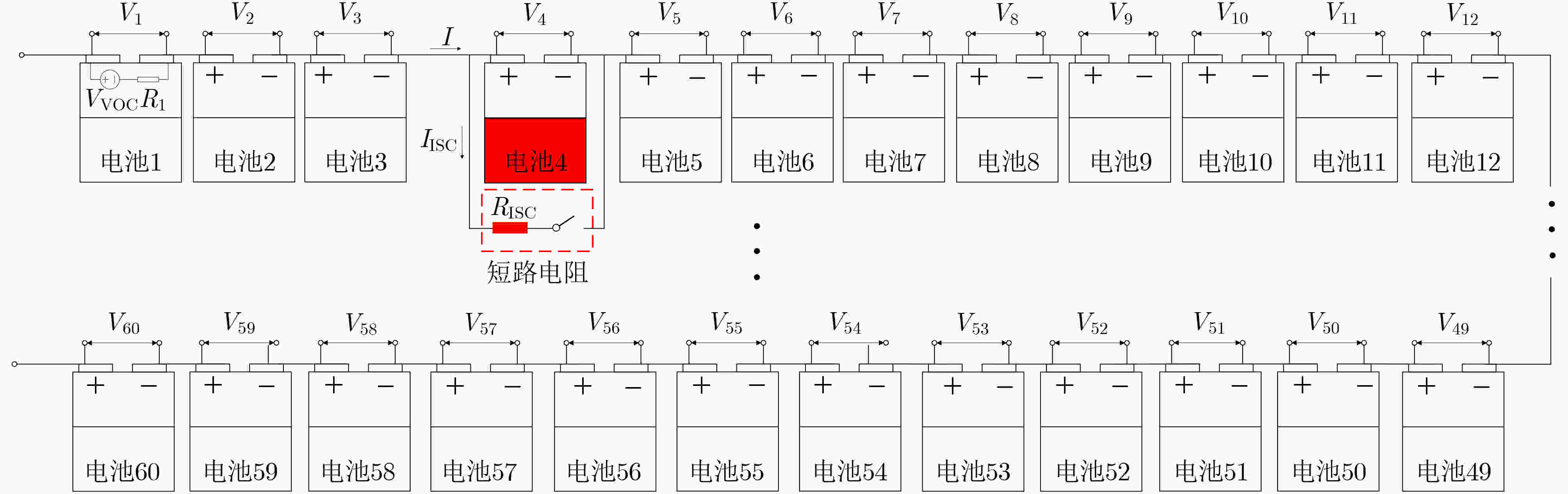

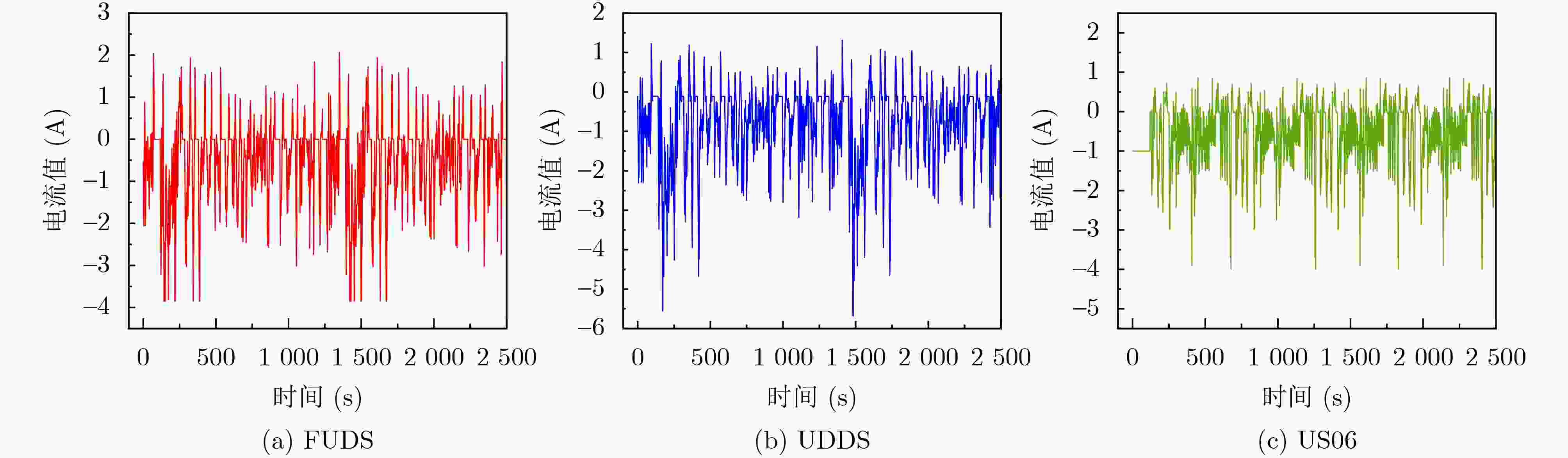

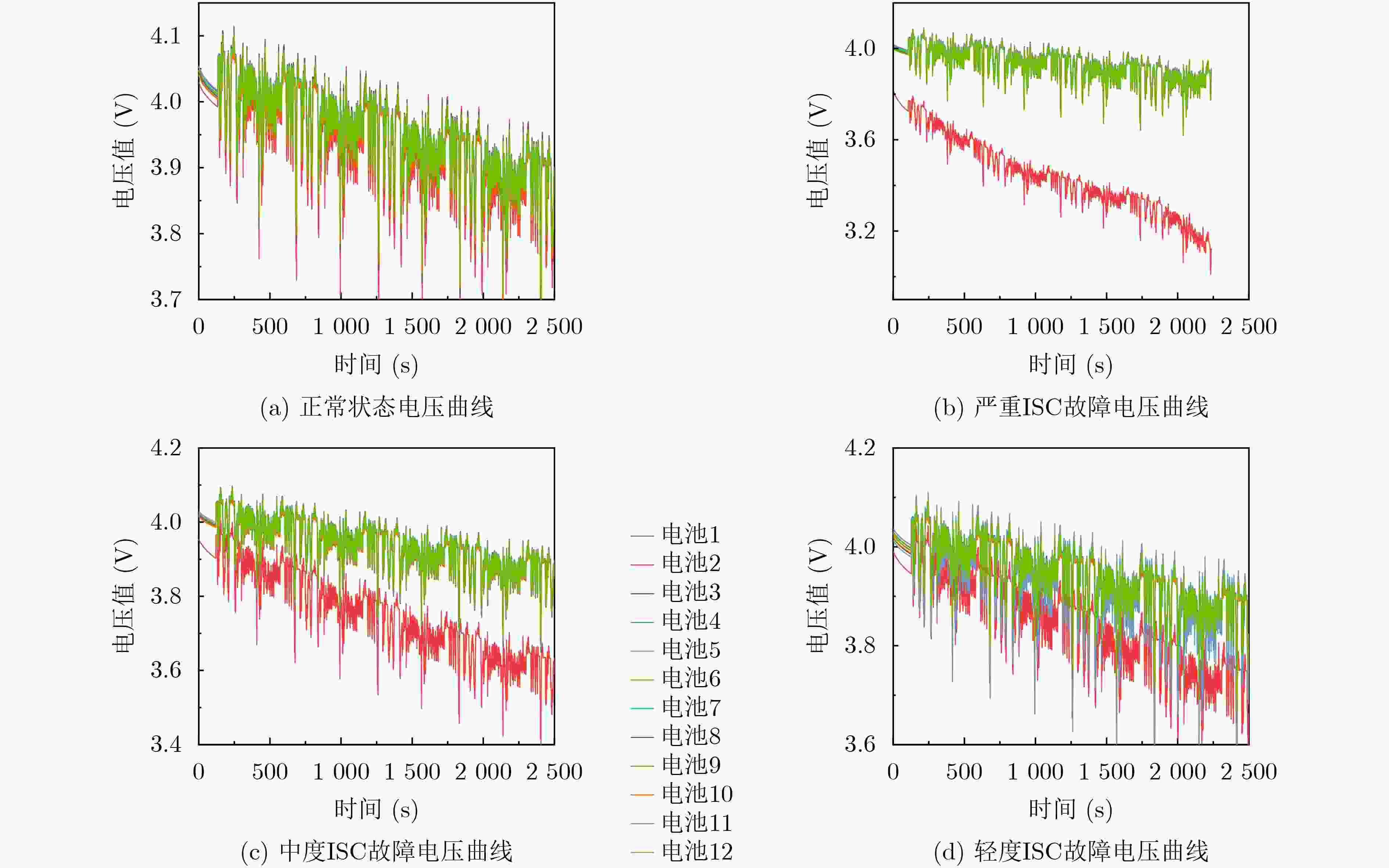

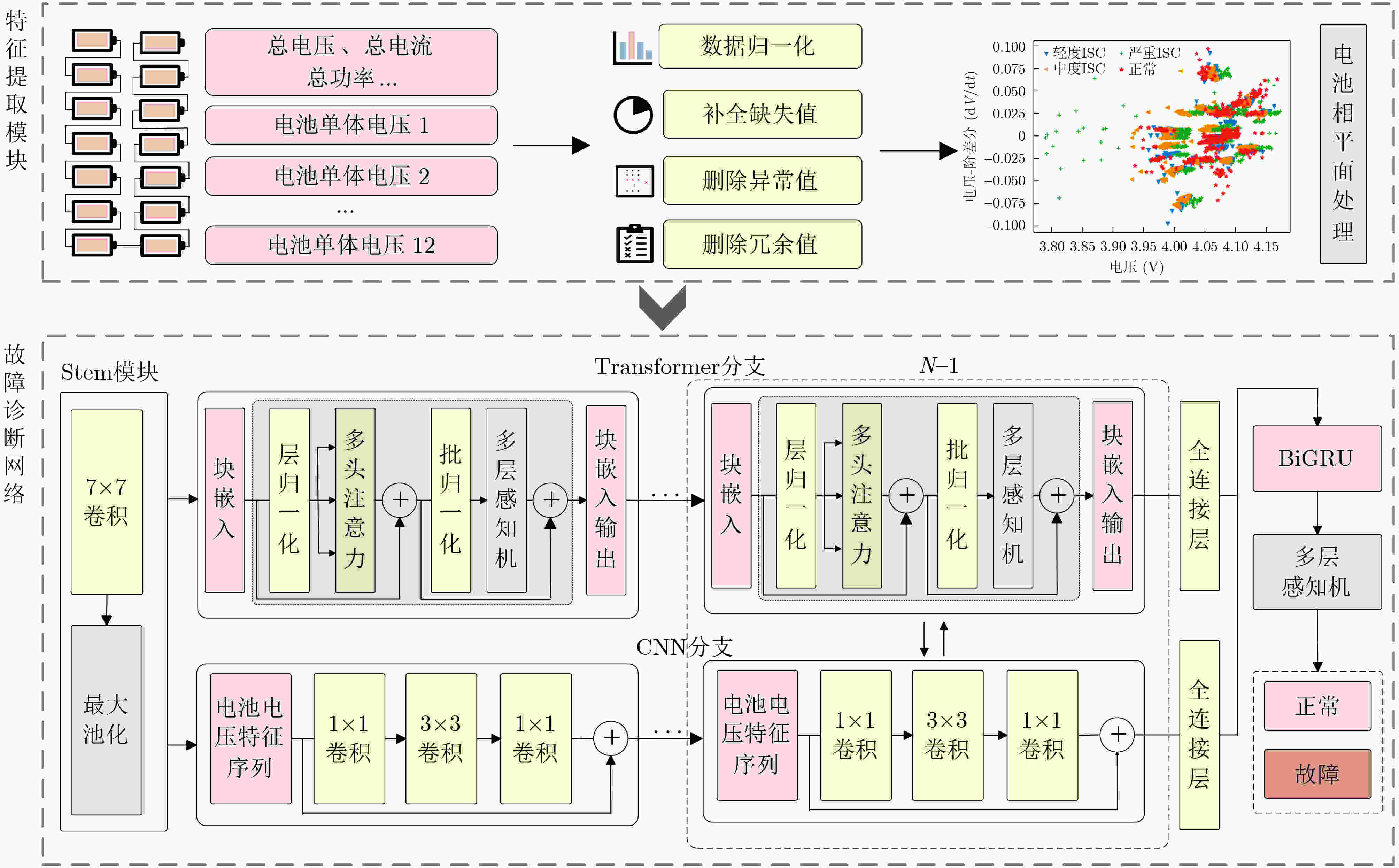

摘要: 近年来,新能源汽车凭借环保与高效的优势迅速崛起,然而随着其市场规模的持续扩大,新能源汽车故障频发,安全性问题日益凸显。其中,内短路故障因其隐蔽性强、危害性大,成为最常见且最具威胁的故障之一。若不进行准确的诊断和处理,可能会导致严重的安全事故。因此,开发高效且精准的内短路故障诊断方法具有重要的现实意义。该文提出了一种电池相平面方法结合卷积增强Transformer-双向门控循环单元(Conformer-BiGRU)网络的电池包内短路故障诊断方法。首先,利用改进的电池相平面对电池电压序列进行二维特征提取,以捕捉更深层次的空间和结构信息。其次,提出Conformer-BiGRU网络对电池电压序列进行特征学习。该网络包含卷积神经网络(CNN)分支和Transformer分支,用于提取局部特征和全局表示,通过特征耦合单元融合后输入BiGRU模块,对电池包中的电池单体进行分类,判断是否存在内短路故障。该文基于实验平台采集的故障数据对所提出的方法进行测试,其严重内短路故障的精确率在3种国际标准工况下分别达到94.30%, 92.77%和94.85%。同时,该方法在轻度、中度和严重内短路故障数据集中,所提出方法的和F1分数在3种工况下平均达到91.26%, 85.17%和88.09%。实验结果表明该方法具有更好的鲁棒性,为提升新能源汽车的安全性提供了新的解决方案。Abstract:

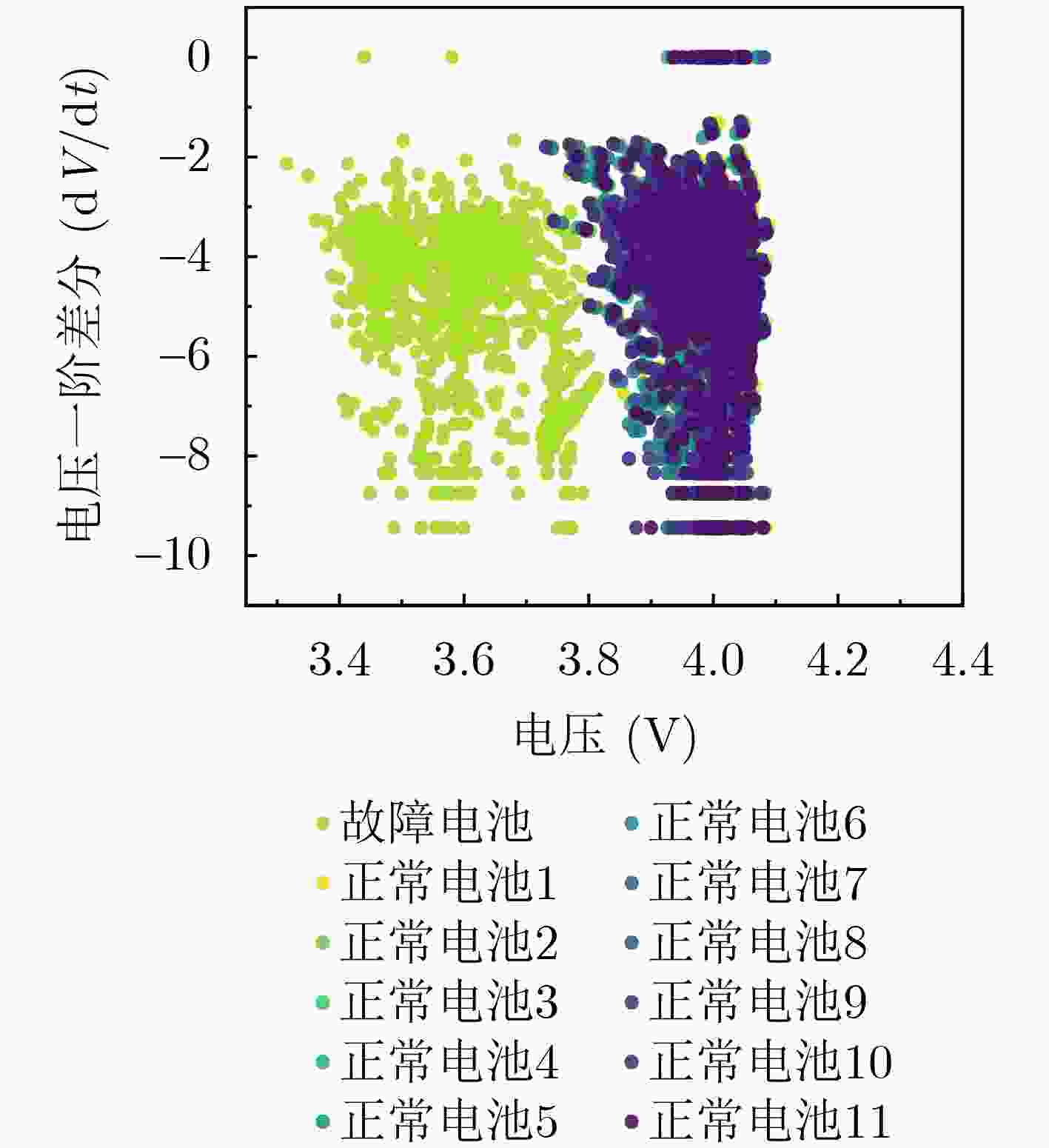

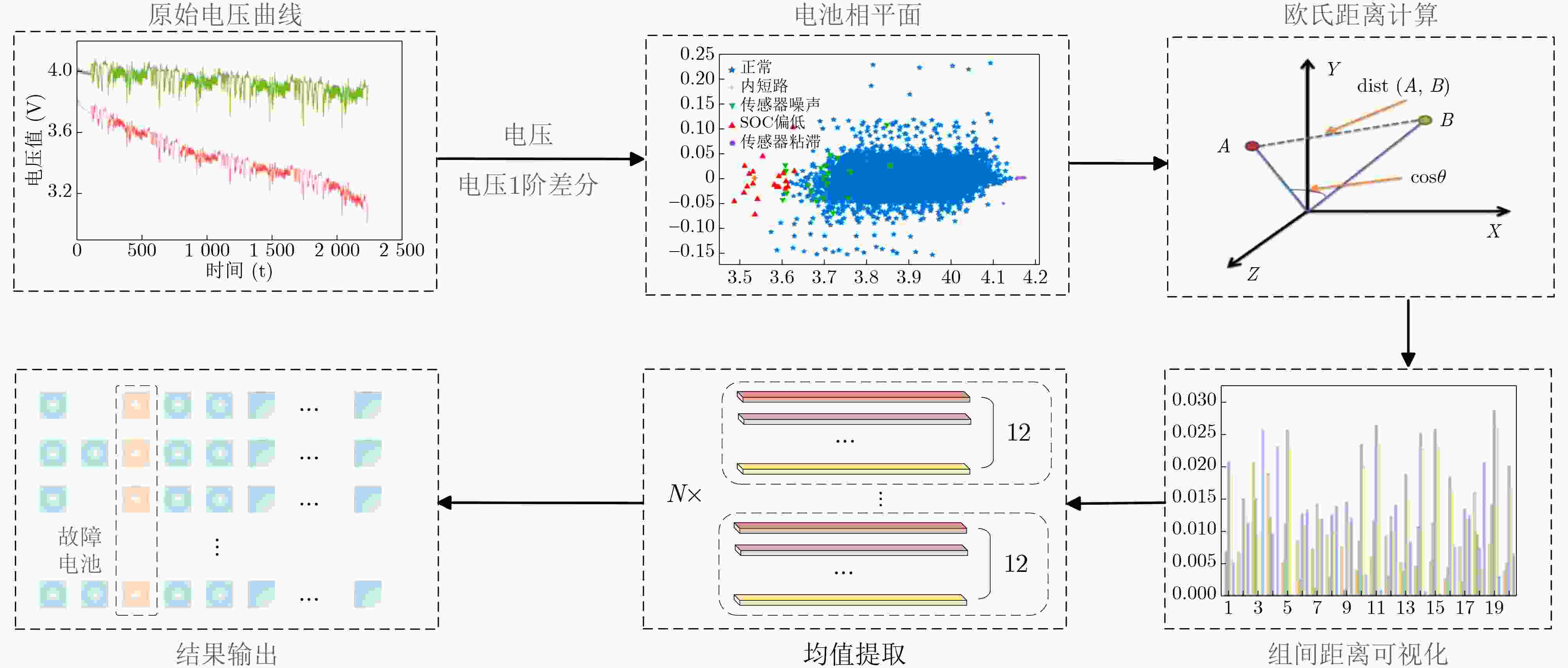

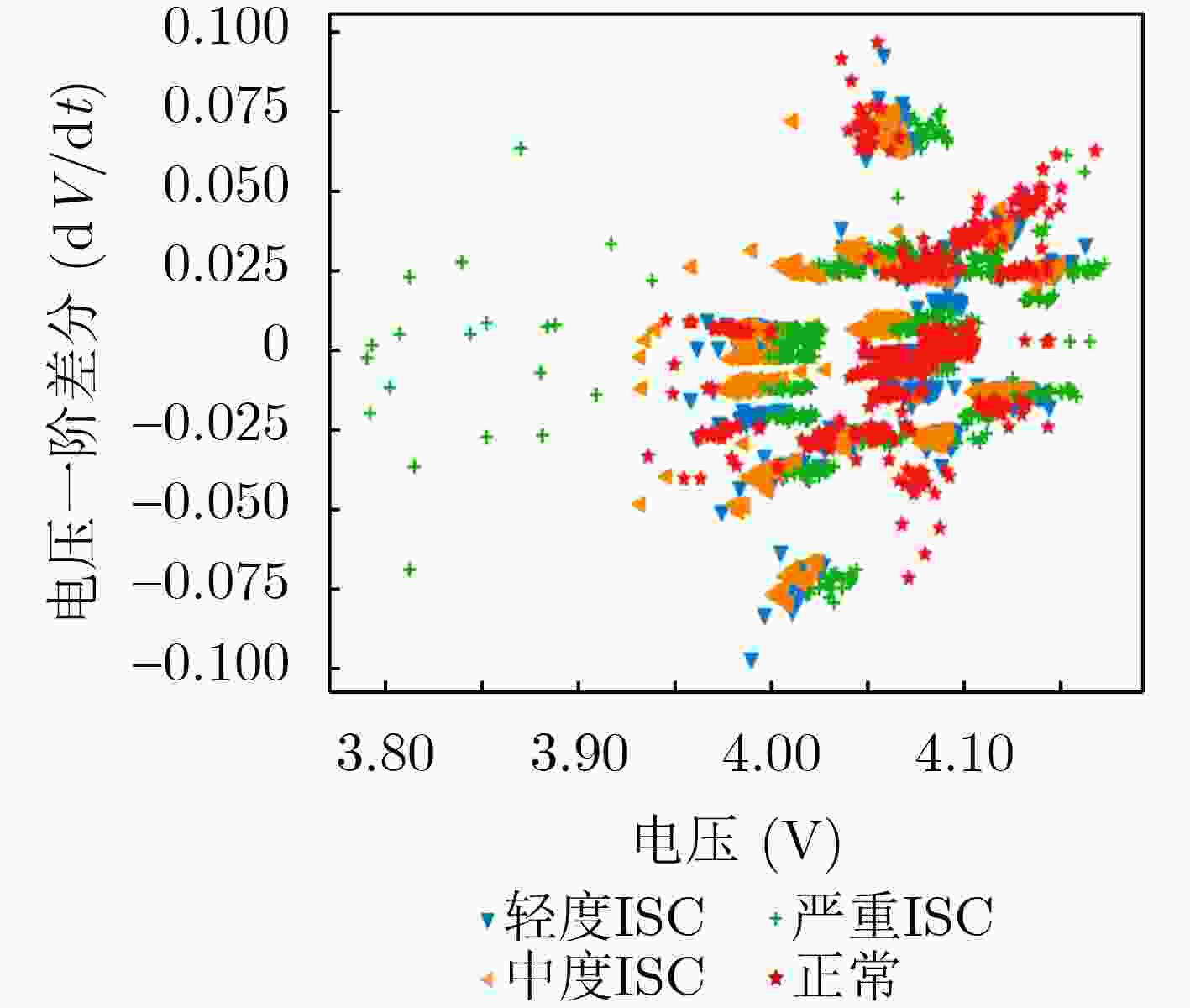

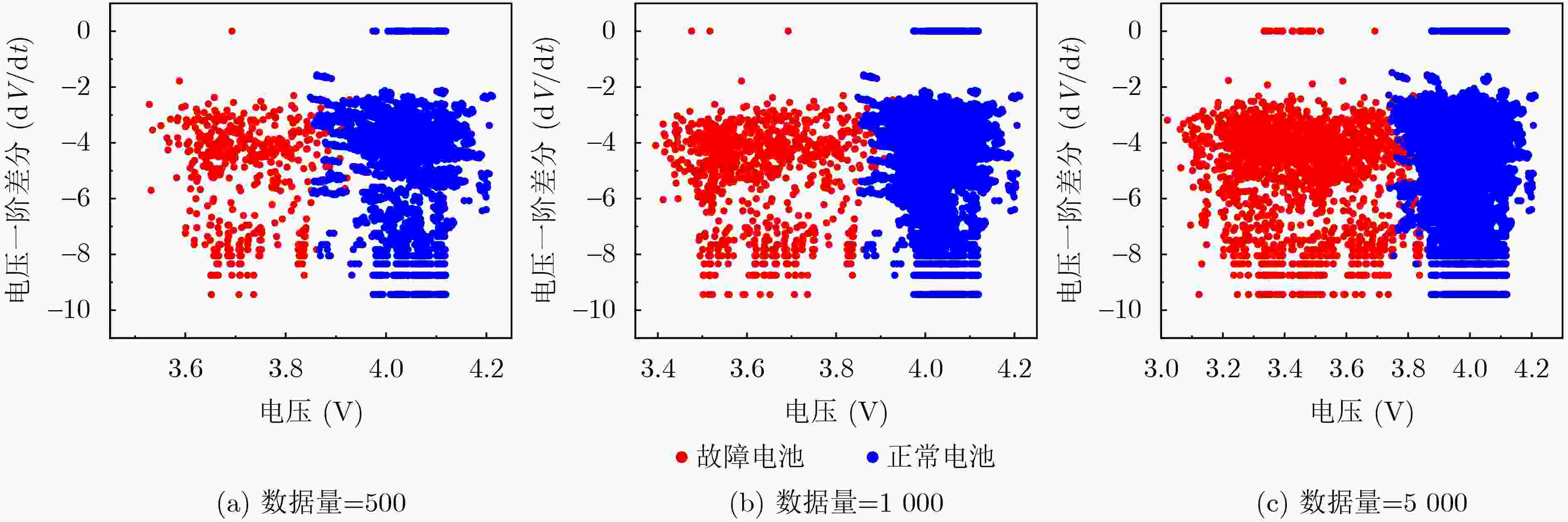

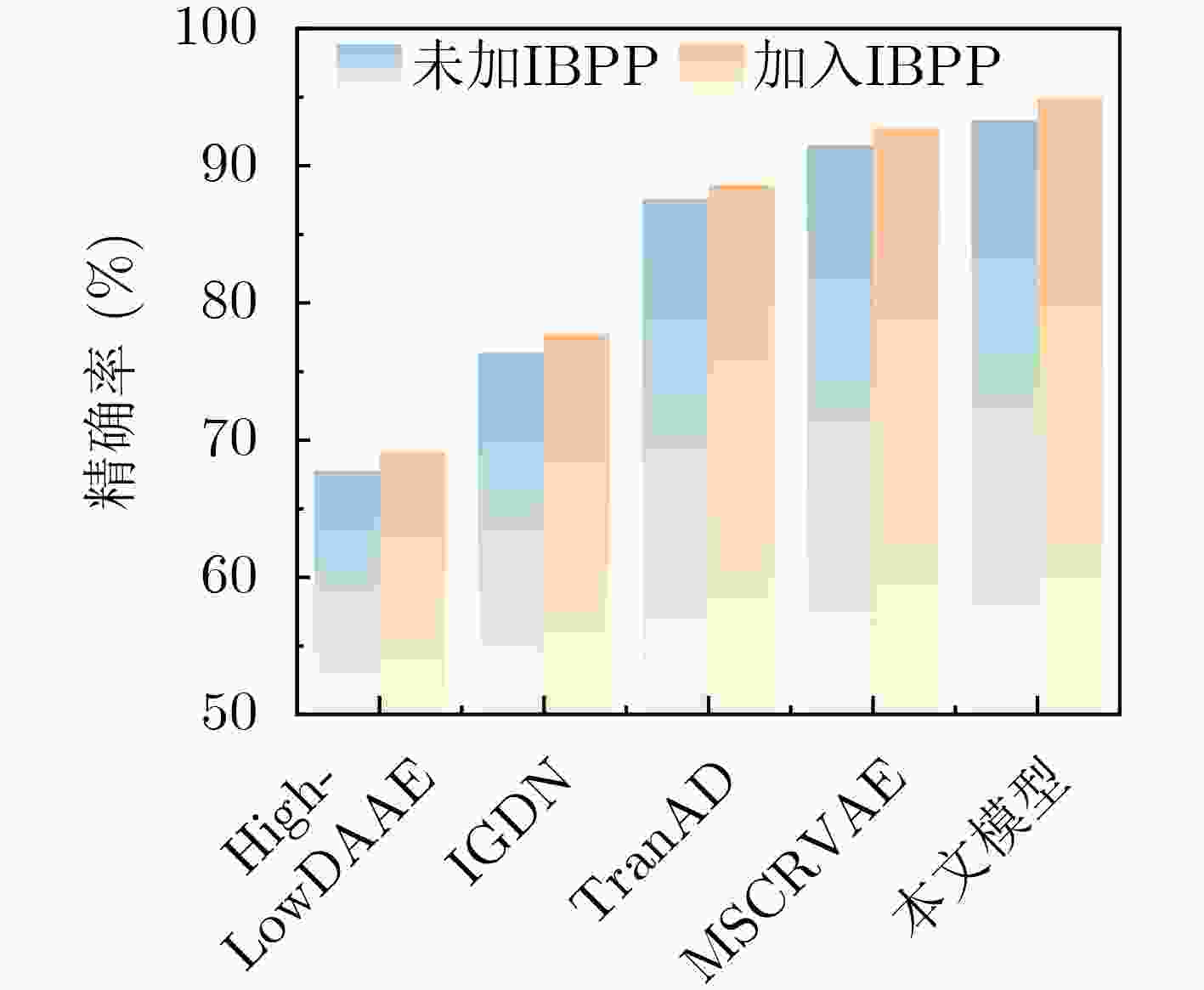

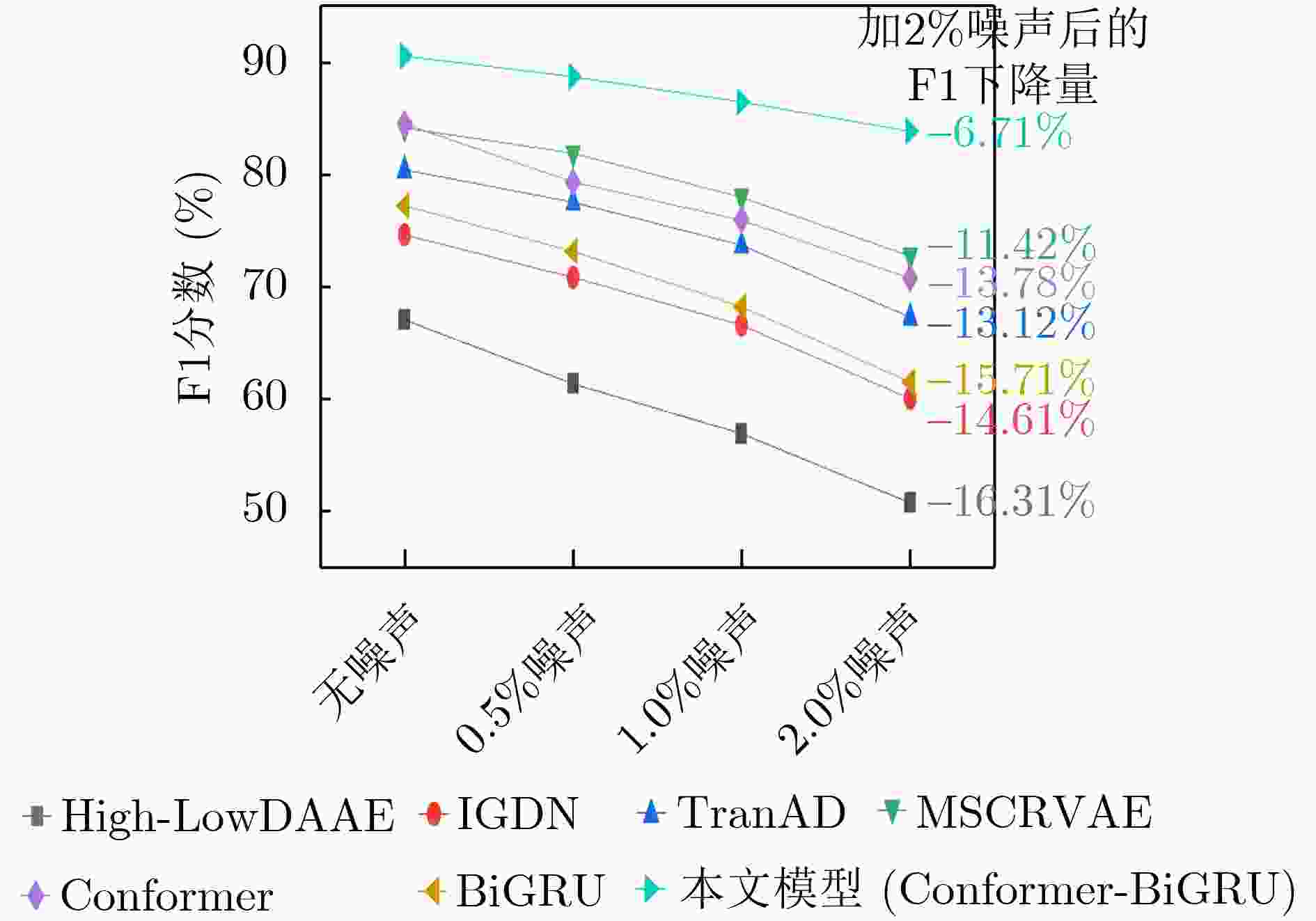

Objective New Energy Vehicles (NEVs) have gained rapid popularity in recent years due to their environmental benefits and high efficiency. However, as their market share continues to grow, concerns regarding frequent malfunctions and safety risks have also increased. Among these issues, Internal Short Circuit (ISC) faults are particularly concerning due to their strong concealment and the potential for severe consequences. Without accurate diagnosis and timely intervention, ISC faults can result in serious safety incidents. Therefore, developing efficient and reliable diagnostic methods for ISC faults is of practical significance. Methods A novel ISC fault diagnosis method is proposed for battery packs by combining an improved battery phase plane approach with a Conformer-BiGRU network. First, the improved battery phase plane method is employed to extract two-dimensional features from voltage sequences, providing deeper spatial and structural information. Second, a Conformer-BiGRU network is employed to learn features from the voltage data. The network integrates a CNN branch for local feature extraction and a Transformer branch for global representation. A feature coupling unit fuses the outputs of both branches, which are then passed to a BiGRU module to classify individual cells within the battery pack and detect ISC faults. Results and Discussions The proposed method is evaluated using fault data collected from an experimental platform. The results demonstrate that the improved battery phase plane effectively distinguishes between normal and faulty batteries within a two-dimensional plane ( Figure 6 ) and further confirm its capability to detect ISC faults with varying severity under different data volumes (Figure 9 ). Using the Conformer-BiGRU network for fault diagnosis, the method achieves classification accuracies of 94.30%, 92.77%, and 94.85% under FUDS, UDDS, and US06 operating conditions, respectively (Table 3 ), significantly exceeding the performance of comparative models. Additionally, the feature extraction module contributes to an overall performance improvement of approximately 2.04% (Table 5 ). These findings indicate that the proposed method exhibits strong robustness (Table 6 andFigure 11 ) and offers a promising approach for enhancing the safety of NEVs.Conclusions This study proposes a novel method for diagnosing ISC faults in battery packs by integrating an improved battery phase plane approach with a Conformer-BiGRU network. The main contributions are as follows: First, the improved battery phase plane method enhances the separability of different fault states in two-dimensional space by incorporating both voltage and its first-order differential distribution, addressing the limitations of conventional one-dimensional feature extraction. Second, a hybrid Conformer-BiGRU architecture is developed, in which the Conformer module captures local discharge characteristics, while the BiGRU module models temporal dependencies. These features are integrated through a feature coupling unit to achieve cross-level feature fusion. Third, an experimental ISC fault dataset with varying severity levels is established using a self-built testing platform. Experimental results demonstrate average diagnostic accuracy, recall, and F1-scores of 91.26%, 85.17%, and 88.09%, respectively, across three international driving cycles. Although laboratory testing verifies the effectiveness of the proposed method, real-world application requires targeted optimization. This includes adapting BiGRU parameters during the migration of the Improved Battery Phase Plane (IBPP) module and refining the Conformer’s local perception weights through transfer learning to enhance feature decoupling. Future research focuses on improving diagnostic performance under concurrent fault scenarios to enhance engineering robustness in complex operating conditions. -

Key words:

- New energy vehicles /

- Battery packs /

- Fault diagnosis /

- Internal Short Circuit (ISC)

-

表 1 数据类型及规模

测试工况 FUDS UDDS US06 数据类型 正常 内短路 正常 内短路 正常 内短路 轻度 中度 严重 轻度 中度 严重 轻度 中度 严重 数据总长 93395 28060 27395 11580 82535 26465 24890 10690 85060 26795 26450 11185 表 2 模型超参数表

超参数 取值 超参数 取值 超参数 取值 超参数 取值 输入维度 12 批大小 128 嵌入维度 32 学习率 1e–3 输出维度 2 训练次数 100 Transformer层数 4 激活函数 Softmax 输入长度 25 Dropout 0.5 BiGRU隐藏单元 64 优化算法 Adam 表 3 各模型在FUDS, UDDS, US06工况下的指标结果(%)

模型 故障程度 UDDS FUDS US06 精确率 召回率 F1分数 精确率 召回率 F1分数 精确率 召回率 F1分数 High-LowDAAE[30] 轻度 50.83 74.27 60.35 45.14 71.52 55.34 58.07 79.21 67.01 中度 59.58 72.76 65.51 56.26 70.21 62.46 65.19 77.55 70.83 严重 64.21 76.24 69.70 63.12 73.14 67.76 67.78 81.04 73.82 IGDN[31] 轻度 62.49 80.85 70.49 59.57 76.56 67.00 68.63 81.69 74.59 中度 70.83 79.51 74.92 66.81 76.83 71.47 72.81 82.26 77.24 严重 74.74 84.66 79.39 73.40 82.71 77.78 76.34 86.50 81.10 TranAD[32] 轻度 76.91 72.30 74.53 73.68 81.12 77.22 79.82 80.96 80.38 中度 81.15 76.25 78.62 77.02 85.52 81.04 82.29 84.99 83.62 严重 85.35 77.86 81.43 79.22 86.84 82.85 87.60 82.41 84.92 MSCRVAE[33] 轻度 80.87 75.26 77.96 79.73 82.92 81.29 87.25 81.18 84.11 中度 84.02 77.74 80.75 81.66 82.54 82.10 90.53 81.77 85.92 严重 86.49 78.91 82.52 83.32 83.49 83.40 91.46 80.92 85.69 Conformer[34] 轻度 83.50 76.10 79.63 85.65 73.62 79.28 89.20 80.25 84.50 中度 86.70 79.35 82.86 87.90 78.55 83.00 90.75 85.40 87.98 严重 91.70 80.12 85.50 89.65 80.01 84.57 91.12 87.22 89.12 BiGRU[35] 轻度 72.30 74.24 73.26 67.30 76.55 71.63 76.60 77.74 77.16 中度 75.21 82.10 78.50 68.10 81.33 74.13 79.35 80.92 80.13 严重 78.30 83.75 80.93 71.80 80.17 75.75 80.75 84.48 82.57 Conformer-BiGRU

(本文模型)轻度 88.17 83.20 85.61 87.61 82.20 84.81 92.32 88.77 90.53 中度 89.55 83.99 86.68 89.04 81.33 85.01 92.75 88.92 90.79 严重 94.30 84.76 89.27 92.77 83.21 87.73 94.85 90.13 92.42 表 4 US06工况下各模型的训练时间与推理时间

模型 High-LowDAAE IGDN TranAD MSCRVAE Conformer BiGRU Conformer- BiGRU 单次训练时间(s) 103.2 61.4 155.9 180.3 129.6 86.8 112.7 推理时间(ms) 2.13 3.02 5.31 4.97 3.46 2.41 2.84 表 5 加入特征提取模块(IBPP)后的实验结果(%)

模型 UDDS FUDS US06 精确率 召回率 F1分数 精确率 召回率 F1分数 精确率 召回率 F1分数 High-LowDAAE 63.75 75.50 69.13 62.43 71.33 66.58 69.18 81.99 75.04 IGDN 75.69 82.64 79.01 72.55 82.93 77.93 77.72 85.27 81.32 TranAD 87.92 80.27 83.92 81.84 84.69 83.24 88.59 86.17 87.36 MSCRVAE 89.74 80.45 84.84 84.81 81.29 83.01 92.74 83.54 87.90 Conformer-BiGRU (本文模型) 94.30 84.76 89.27 92.77 83.21 87.73 94.85 90.13 92.42 表 6 数据长度鲁棒性比较(%)

故障程度 精确率 召回率 F1分数 轻度 91.68 87.12 89.34 中度 90.08 88.47 89.26 严重 88.86 87.39 88.11 -

[1] JI Xiaoyue, CHEN Yi, WANG Junfan, et al. Time-frequency hybrid neuromorphic computing architecture development for battery state-of-health estimation[J]. IEEE Internet of Things Journal, 2024, 11(24): 39941–39957. doi: 10.1109/JIOT.2024.3448350. [2] HU Shimin, LIU Zhihui, TAN Yongshi, et al. The status quo and future trends of new energy vehicle power batteries in China—analysis from policy perspective[J]. Energy Reports, 2022, 8(S8): 63–80. doi: 10.1016/j.egyr.2022.09.082. [3] 丁徐强, 陶琦, 罗鹰. 锂离子电池在新能源汽车中的设计及应用[J]. 储能科学与技术, 2023, 12(5): 1751–1752.DING Xuqiang, TAO Qi, and LUO Ying. Design and application of lithium-ion batteries in new energy vehicles[J]. Energy Storage Science and Technology, 2023, 12(5): 1751–1752. [4] KHAN F M N U, RASUL M G, SAYEM A S M, et al. Maximizing energy density of lithium-ion batteries for electric vehicles: A critical review[J]. Energy Reports, 2023, 9(S11): 11–21. doi: 10.1016/j.egyr.2023.08.069. [5] XU Jingjing, CAI Xinyun, CAI Songming, et al. High‐energy lithium‐ion batteries: Recent progress and a promising future in applications[J]. Energy & Environmental Materials, 2023, 6(5): e12450. doi: 10.1002/eem2.12450. [6] SEPASIAHOOYI S and ABDOLLAHI F. Fault detection of new and aged lithium-ion battery cells in electric vehicles[J]. Green Energy and Intelligent Transportation, 2024, 3(3): 100165. doi: 10.1016/j.geits.2024.100165. [7] 朱晓庆, 王震坡, WANG H, 等. 锂离子动力电池热失控与安全管理研究综述[J]. 机械工程学报, 2020, 56(14): 91–118. doi: 10.3901/JME.2020.14.091.ZHU Xiaoqing, WANG Zhenpo, WANG H, et al. Review of thermal runaway and safety management for lithium-ion traction batteries in electric vehicles[J]. Journal of Mechanical Engineering, 2020, 56(14): 91–118. doi: 10.3901/JME.2020.14.091. [8] REN Dongsheng, FENG Xuning, LIU Lishuo, et al. Investigating the relationship between internal short circuit and thermal runaway of lithium-ion batteries under thermal abuse condition[J]. Energy Storage Materials, 2021, 34: 563–573. doi: 10.1016/j.ensm.2020.10.020. [9] 陈泽宇, 熊瑞, 孙逢春. 电动汽车电池安全事故分析与研究现状[J]. 机械工程学报, 2019, 55(24): 93–104. doi: 10.3901/JME.2019.24.093.CHEN Zeyu, XIONG Rui, and SUN Fengchun. Research status and analysis for battery safety accidents in electric vehicles[J]. Journal of Mechanical Engineering, 2019, 55(24): 93–104. doi: 10.3901/JME.2019.24.093. [10] CORTADA-TORBELLINO M, ELVIRA D G, EL AROUDI A, et al. Review of lithium-ion battery internal changes due to mechanical loading[J]. Batteries, 2024, 10(7): 258. doi: 10.3390/batteries10070258. [11] KONG Jinzhen, LIU Jie, ZHU Jingzhe, et al. Review on lithium-ion battery PHM from the perspective of key PHM steps[J]. Chinese Journal of Mechanical Engineering, 2024, 37(1): 71. doi: 10.1186/s10033-024-01055-z. [12] ZHAO Hongqian, ZHAO Zhigang, SHU Xing, et al. Voltage fault diagnosis and prognostic of lithium-ion batteries in electric scooters based on hybrid neural network and multiple thresholds[J]. Journal of Power Sources, 2024, 618: 235197. doi: 10.1016/j.jpowsour.2024.235197. [13] ZHAO Jiahui, LIU Mingyi, ZHANG Bin, et al. Review of lithium-ion battery fault features, diagnosis methods, and diagnosis procedures[J]. IEEE Internet of Things Journal, 2024, 11(11): 18936–18950. doi: 10.1109/JIOT.2023.3324322. [14] KONG Xiangdong, ZHENG Yuejiu, OUYANG Minggao, et al. Fault diagnosis and quantitative analysis of micro-short circuits for lithium-ion batteries in battery packs[J]. Journal of Power Sources, 2018, 395: 358–368. doi: 10.1016/j.jpowsour.2018.05.097. [15] ZHANG Zhaosheng, BI Jiyu, LI Da, et al. Battery defect detection for real world vehicles based on Gaussian distribution parameterization developed LCSS[J]. Journal of Energy Storage, 2024, 75: 109679. doi: 10.1016/j.est.2023.109679. [16] PAN Tinglong, YU Ziyi, MA Shunshun, et al. Detection of internal short circuit in lithium-ion batteries based on electrothermal coupling model[J]. Journal of Energy Storage, 2025, 106: 114685. doi: 10.1016/j.est.2024.114685. [17] OUYANG Minggao, ZHANG Mingxuan, FENG Xuning, et al. Internal short circuit detection for battery pack using equivalent parameter and consistency method[J]. Journal of Power Sources, 2015, 294: 272–283. doi: 10.1016/j.jpowsour.2015.06.087. [18] XIA Bing, SHANG Yunlong, NGUYEN T, et al. A correlation based fault detection method for short circuits in battery packs[J]. Journal of Power Sources, 2017, 337: 1–10. doi: 10.1016/j.jpowsour.2016.11.007. [19] 高明裕, 蔡林辉, 孙长城, 等. 一种基于斯皮尔曼秩相关结合神经网络的电池组内部短路故障检测算法[J]. 电子与信息学报, 2022, 44(11): 3734–3747. doi: 10.11999/JEIT210975.GAO Mingyu, CAI Linhui, SUN Changcheng, et al. An internal short circuit fault detecting of battery pack based on spearman rank correlation combined with neural network[J]. Journal of Electronics & Information Technology, 2022, 44(11): 3734–3747. doi: 10.11999/JEIT210975. [20] CHEN Siwen, SUN Jinlei, TANG Yong, et al. A fault diagnosis method of battery internal short circuit based on multi-feature recognition[J]. Transactions of the Institute of Measurement and Control, 2024, 46(11): 2186–2197. doi: 10.1177/01423312241233799. [21] ZHANG Kai, JIANG Lulu, DENG Zhongwei, et al. An early soft internal short-circuit fault diagnosis method for lithium-ion battery packs in electric vehicles[J]. IEEE/ASME Transactions on Mechatronics, 2023, 28(2): 644–655. doi: 10.1109/TMECH.2023.3234770. [22] GU Xin, LI Jinglun, LIU Kailong, et al. A precise minor-fault diagnosis method for lithium-ion batteries based on phase plane sample entropy[J]. IEEE Transactions on Industrial Electronics, 2024, 71(8): 8853–8861. doi: 10.1109/TIE.2023.3319717. [23] LUCAFERRI V, QUERCIO M, LAUDANI A, et al. A review on battery model-based and data-driven methods for battery management systems[J]. Energies, 2023, 16(23): 7807. doi: 10.3390/en16237807. [24] 耿陈, 彭乔, 孟锦豪, 等. 考虑弛豫过程的锂离子电池电-热-老化耦合建模[J]. 电力自动化设备, 2025, 45(3): 33–39. doi: 10.16081/j.epae.202501001.GENG Chen, PENG Qiao, MENG Jinhao, et al. Coupled electro-thermal-aging modeling for lithium-ion battery considering relaxation process[J]. Electric Power Automation Equipment, 2025, 45(3): 33–39. doi: 10.16081/j.epae.202501001. [25] LI Jinglun, GU Xin, MAO Ziheng, et al. An early-fault diagnostic method based on phase plane for lithium-ion batteries under complex operation conditions[J]. Journal of Energy Storage, 2024, 96: 112638. doi: 10.1016/j.est.2024.112638. [26] SHAFIQ M and GU Zhaoquan. Deep residual learning for image recognition: A survey[J]. Applied Sciences, 2022, 12(18): 8972. doi: 10.3390/app12188972. [27] DOSOVITSKIY A, BEYER L, KOLESNIKOV A, et al. An image is worth 16x16 words: Transformers for image recognition at scale[J]. arXiv preprint arXiv: 2010.11929, 2020. [28] LIU Xuyang, CAI Hongchang, ZHOU Zihan, et al. Enhancing multi-type fault diagnosis in lithium-ion battery systems: Vision transformer-based transfer learning approach[J]. Journal of Power Sources, 2024, 624: 235610. doi: 10.1016/j.jpowsour.2024.235610. [29] 张照娓, 郭天滋, 高明裕, 等. 电动汽车锂离子电池荷电状态估算方法研究综述[J]. 电子与信息学报, 2021, 43(7): 1803–1815. doi: 10.11999/JEIT200487.ZHANG Zhaowei, GUO Tianzi, GAO Mingyu, et al. Review of SoC estimation methods for electric vehicle li-ion batteries[J]. Journal of Electronics & Information Technology, 2021, 43(7): 1803–1815. doi: 10.11999/JEIT200487. [30] TANG Chao, QIN Yunchuan, LIU Yumeng, et al. An efficient method for detecting abnormal electricity behavior[J]. Energies, 2024, 17(11): 2502. doi: 10.3390/en17112502. [31] SUN Bingxu, LIANG Dekuan, and ZHANG Hanyuan. An improved graph deviation network for chiller fault diagnosis by integrating the sparse cointegration analysis and the convolutional block attention mechanism[J]. Energies, 2024, 17(16): 4003. doi: 10.3390/en17164003. [32] WANG Dantong, RUAN Pan, XU Di, et al. TranAD: A deep transformer model for fault diagnosis of lithium batteries[C]. Proceedings of the 2023 International Conference on Smart Electrical Grid and Renewable Energy (SEGRE), Changsha, China, 2023: 133–139. doi: 10.1109/SEGRE58867.2023.00028. [33] XIE Tianming, XU Qifa, and JIANG Cuixia. Anomaly detection for multivariate times series through the multi-scale convolutional recurrent variational autoencoder[J]. Expert Systems with Applications, 2023, 231: 120725. doi: 10.1016/j.eswa.2023.120725. [34] GAO Zhengpeng, CHANG Penghui, PENG Yongjun, et al. Multi-feature weighted battery pack consistency evaluation based on massive real-world data[J]. Journal of Energy Storage, 2025, 115: 115919. doi: 10.1016/j.est.2025.115919. [35] HAN Yan, LIU Yang, HUANG Qingqing, et al. SOC estimation for lithium-ion batteries based on BiGRU with SE attention and Savitzky-Golay filter[J]. Journal of Energy Storage, 2024, 90: 111930. doi: 10.1016/j.est.2024.111930. -

下载:

下载:

下载:

下载: