Hybrid Vibration Isolation Design Based on Piezoelectric Actuator and Quasi-zero Stiffness System

-

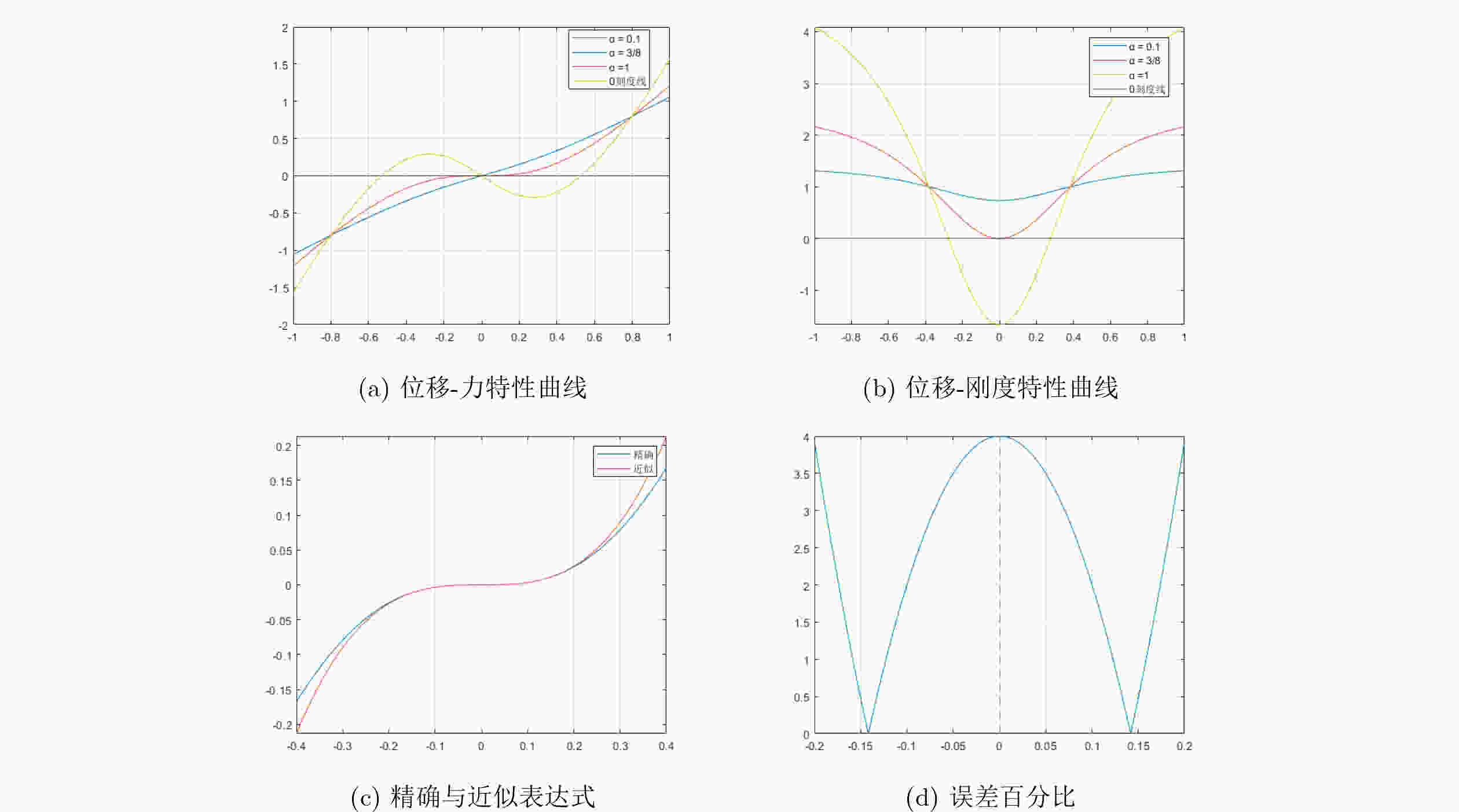

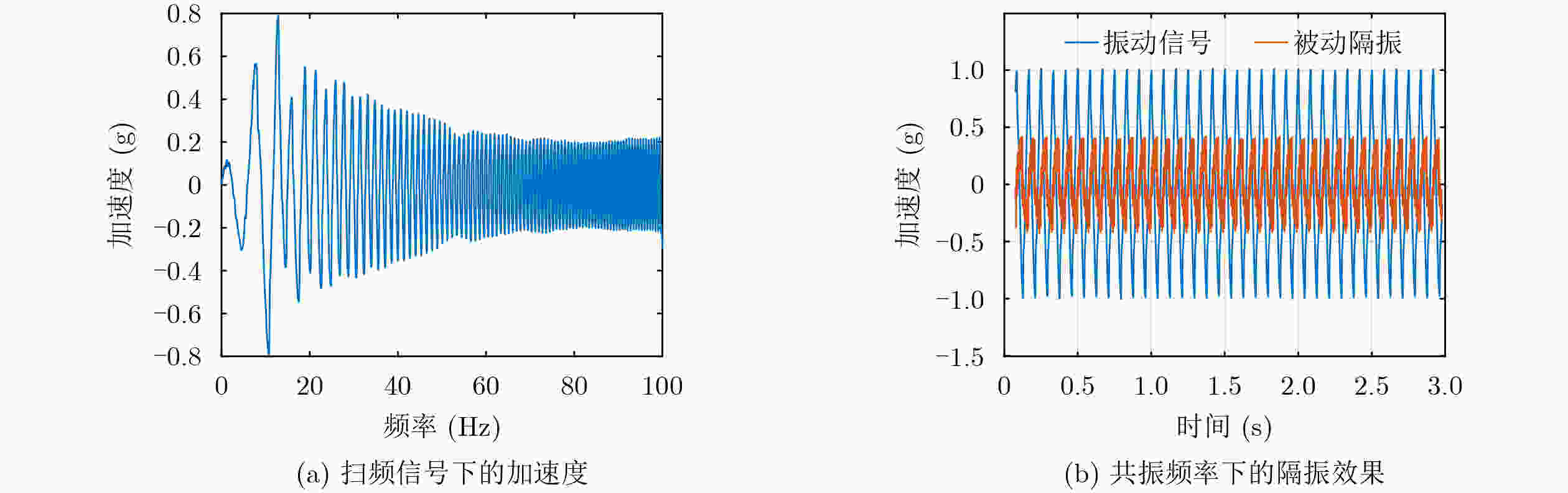

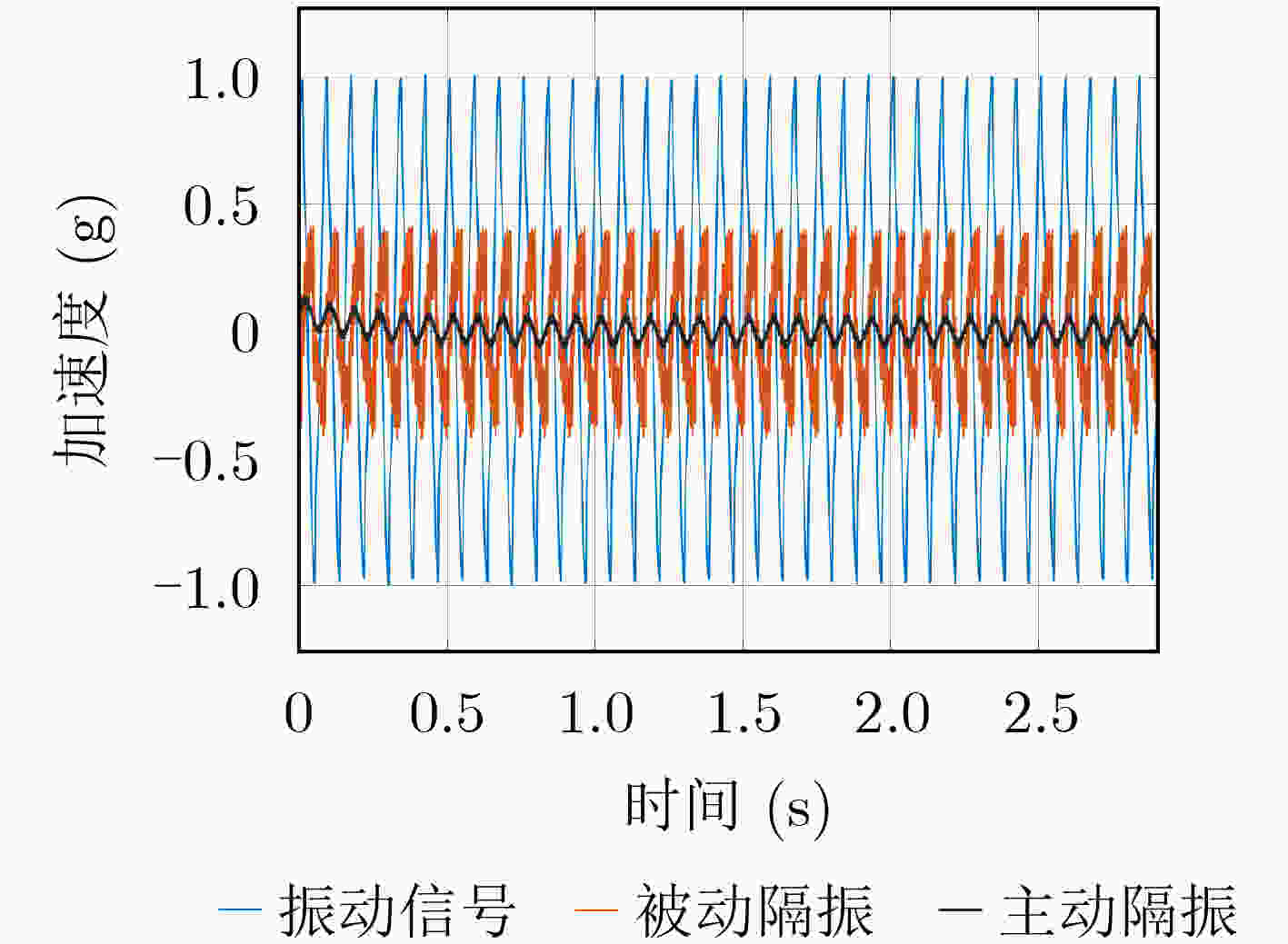

摘要: 低频振动对于精密仪器有着不容忽视的危害,通过弹簧的特殊排列可以实现近零刚度的非线性力学特性,不仅能够显著提高低频隔振效果,而且对于高频率的振动也有一定的隔离效果。然而,基于准零刚度的纯被动系统在动态响应上存在局限性,对振幅的依赖较大。因此,该文提出一种压电作动器的准零刚度混合主被动隔振系统,通过主动控制调节,从而增强混合系统整体的动态性能。首先,搭建基于压电作动器的准零刚度混合系统,由线性弹簧组成的准零刚度装置作为被动隔振装置,压电作动器作为主动隔振装置;其次,提出了一种改进的Bouc-Wen(B-W)模型,通过逆模型对其迟滞非线性进行补偿,对隔振对象施加精准的主动控制;最后,建立系统的动力学方程,对外界振动采用带Luenberger的滑模观测器的自适应滑模控制,提高系统的隔振性能。通过隔振控制实验验证,相比于单一被动隔振装置隔振效果提高35%左右。

-

关键词:

- 主被动隔振 /

- 改进的Bouc-Wen模型 /

- 准零刚度 /

- 压电作动器

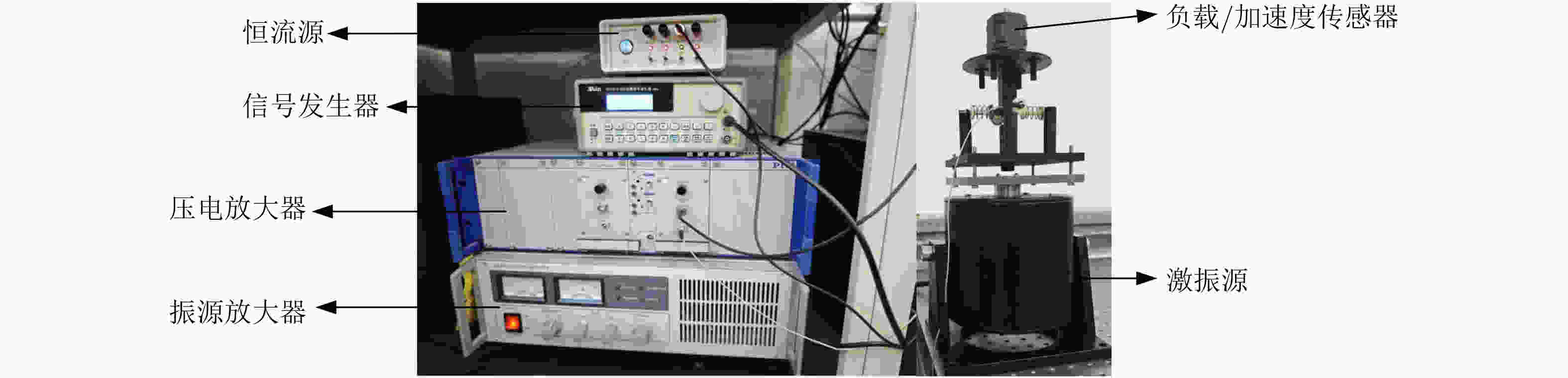

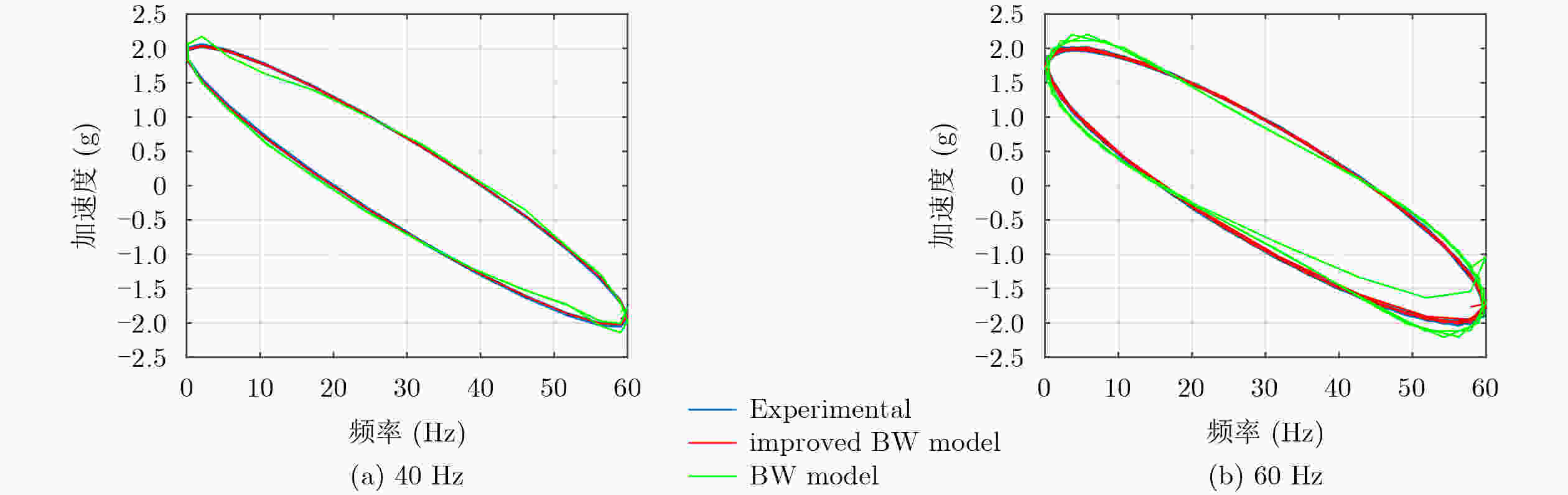

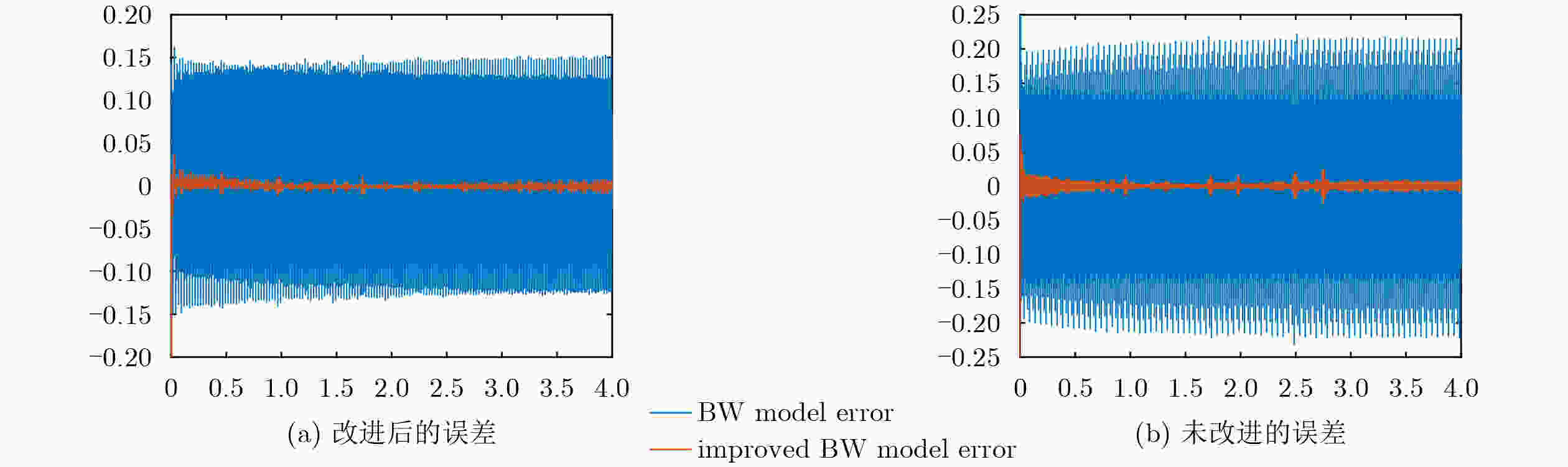

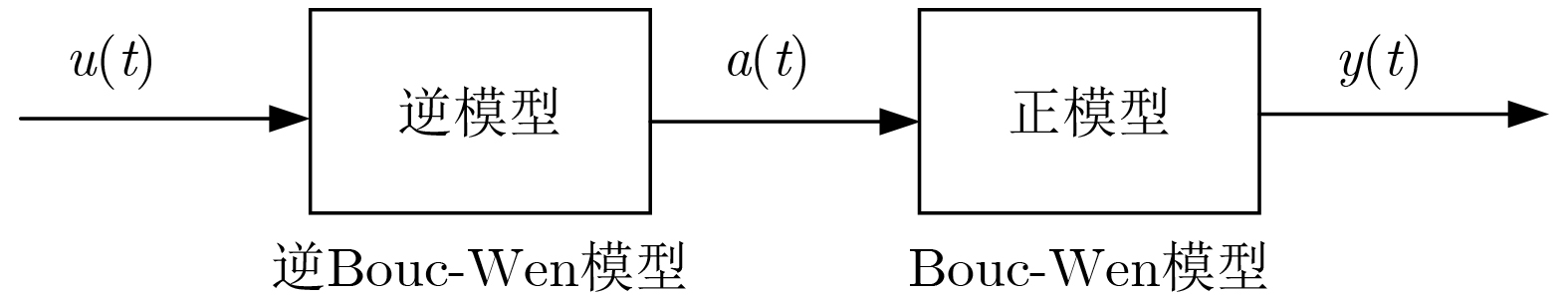

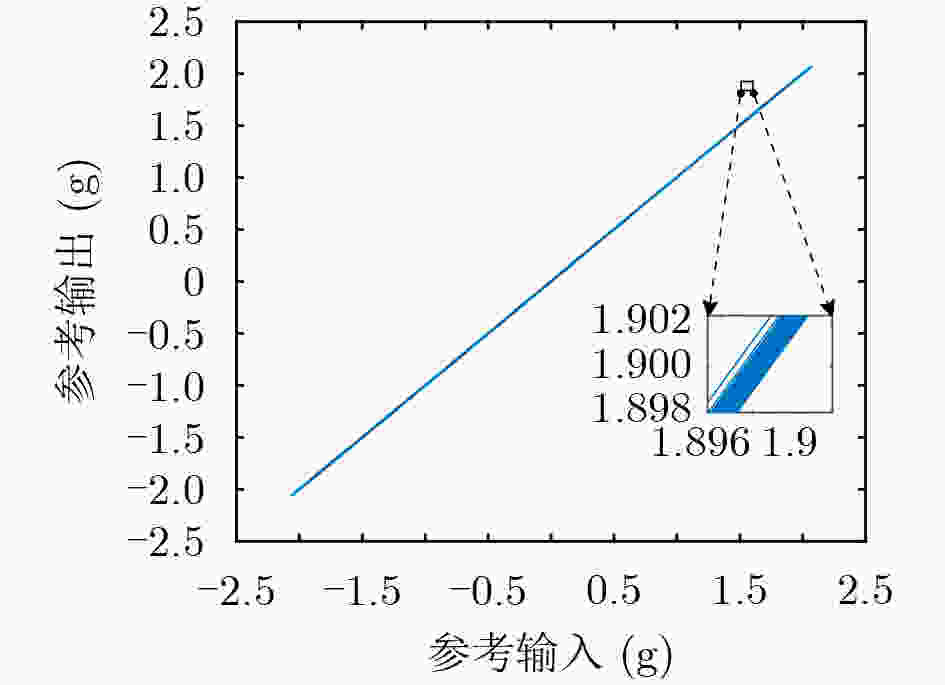

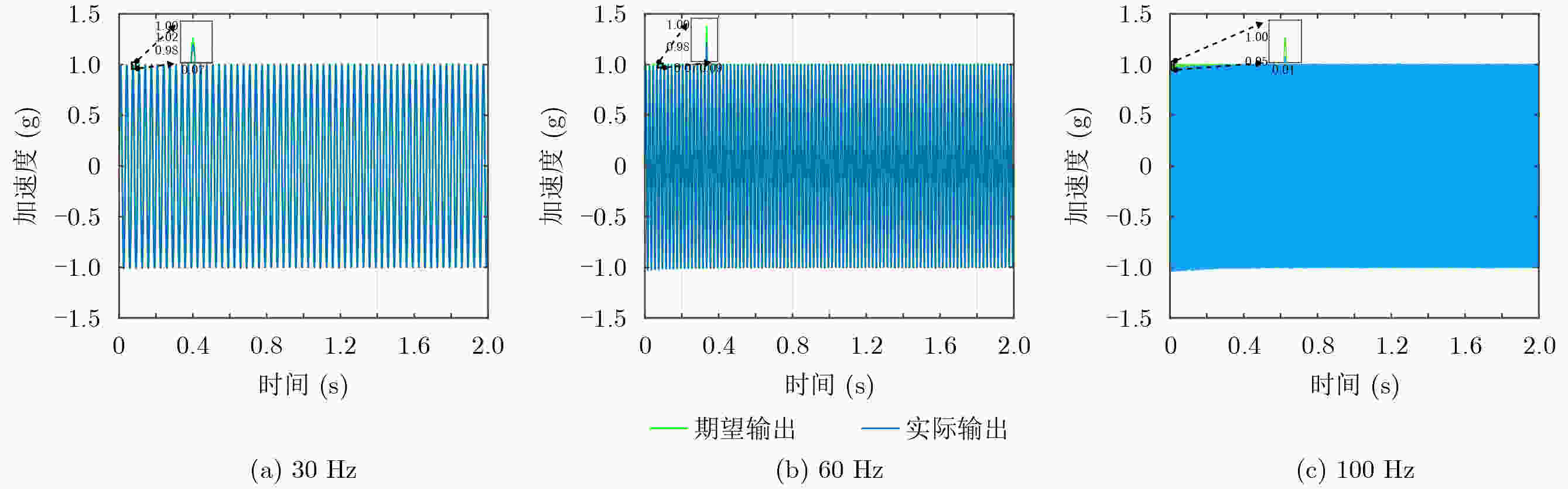

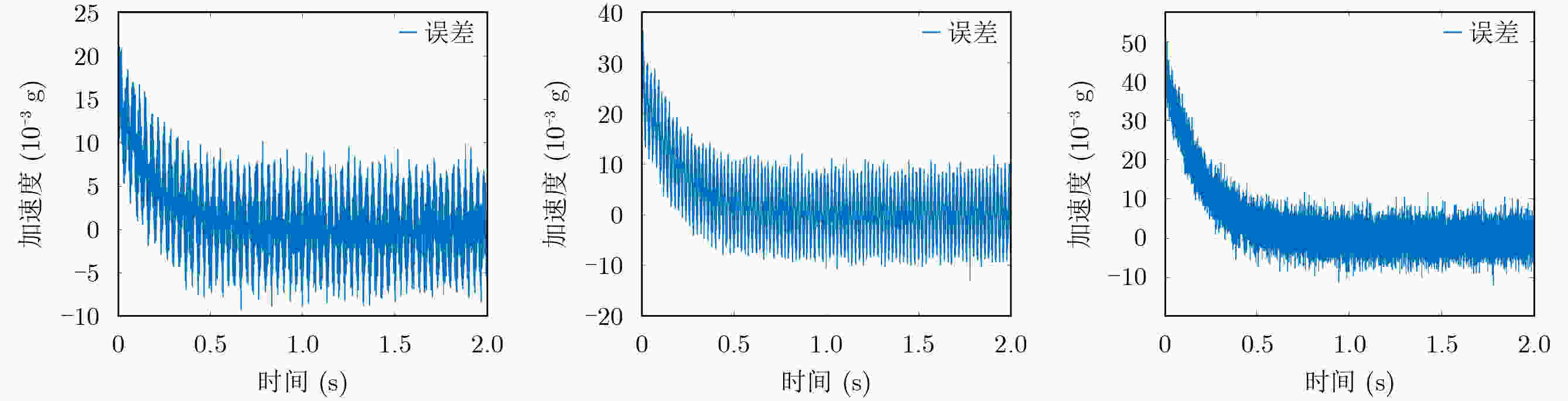

Abstract:Objective Precision instruments now operate under increasingly demanding vibration conditions, and conventional passive isolation methods are insufficient for maintaining stable laboratory environments. Vibrations generated by personnel movement, machinery operation, and vehicle transit can travel long distances and penetrate structural materials, reaching instrument platforms and reducing measurement accuracy, stability, and reliability. Passive isolation units such as rubber elements and springs show limited performance when dealing with low-frequency and small-amplitude excitation. Quasi-Zero Stiffness (QZS) systems improve low-frequency isolation but their performance depends on amplitude and requires strict installation accuracy. Active vibration isolation uses controlled actuators between the vibration source and the support structure to reduce disturbances. Piezoelectric ceramics offer high precision and rapid response, and are widely applied in such systems. Purely active isolation, however, may perform poorly at high frequencies due to sensor sampling limitations and actuator response bandwidth. High-frequency or large-amplitude excitation also results in high actuator energy demand, while the hysteresis characteristics of piezoelectric ceramics reduce control precision. Combining active and passive approaches is therefore an effective strategy for ensuring vibration stability in precision laboratory applications. Methods A hybrid vibration isolation strategy is developed by integrating a piezoelectric actuator with a QZS mechanism. A stacked piezoelectric ceramic actuator is designed to generate the required output force and displacement, and elastic spacers are used to apply a preload that improves operational stability and linearity. The QZS system is formed by combining positive and negative stiffness components to achieve high static stiffness with low dynamic stiffness. To address hysteresis in the piezoelectric actuator, an improved Bouc-Wen (B-W) model is adopted and an inverse model is constructed to enable hysteresis compensation. The actuator is then coupled with the QZS structure, and the vibration isolation performance of the hybrid system is assessed through numerical simulation. Results and Discussions An active-passive vibration isolation device is developed, comprising a QZS system formed by linear springs and an active piezoelectric stack actuator ( Fig. 9a ). Because the traditional B-W algorithm does not accurately describe the dynamic relationship between acceleration and voltage, a voltage-derivative term (Equation 13) is introduced to improve the conventional model. This modification refines the force-voltage representation, enhances model adaptability, and enables accurate description of the acceleration-voltage response over a broader operating range. Forward model parameters are identified using the differential evolution algorithm (Table 1 ), and an inverse model is constructed through direct inversion with parameters obtained using the same optimization method (Table 2 ). The forward and inverse modules are then cascaded to compensate for hysteresis (Fig. 8 ). Dynamic equations for the QZS system and the linearized piezoelectric actuator are derived (Equation 16). An adaptive sliding-mode controller incorporating a Luenberger sliding-mode observer is subsequently designed to regulate vibration signals, and active isolation performance is verified.Conclusions The proposed hybrid vibration isolation design integrates the passive low-frequency isolation capability of the QZS system with the active control potential of the piezoelectric actuator, offering a feasible approach for vibration suppression in precision instruments. The hysteresis behavior of piezoelectric ceramics is characterized and fitted effectively, and an inverse model is established to compensate for the nonlinear voltage-acceleration response. A dynamic model of the combined passive-active configuration is derived, and vibration signals are regulated using adaptive sliding-mode control with a Luenberger sliding-mode observer. The resulting system demonstrates stable vibration reduction, indicating strong applicability and research value. -

表 1 辨识结果

参数 $k$ $\alpha $ $\beta $ $\gamma $ $p$ $b$ 值 – 0.0660 0.0005 0.0127 0.0016 0.0001 1.9788 表 2 辨识结果

参数 $k$ $\alpha $ $\beta $ $\gamma $ $p$ $b$ 值 – 2.4179 2.8832 9.5865 – 4.3025 – 0.0039 0.9871 表 3 均方根误差表

频率(Hz) 均方根误差 30 0.004024 60 0.005977 100 0.064188 -

[1] 孙秀婷, 钱佳伟, 齐志凤, 等. 非线性隔振及时滞消振方法研究进展[J]. 力学进展, 2023, 53(2): 308–356. doi: 10.6052/1000-0992-22-048.SUN Xiuting, QIAN Jiawei, QI Zhifeng, et al. Review on research progress of nonlinear vibration isolation and time-delayed suppression method[J]. Advances in Mechanics, 2023, 53(2): 308–356. doi: 10.6052/1000-0992-22-048. [2] NISTRI F, COSENTINI R M, DAL POGGETTO V F, et al. Attenuation of bulk waves using locally resonant soil-coupled metabarriers[J]. Journal of Physics D: Applied Physics, 2025, 58(4): 045502. doi: 10.1088/1361-6463/ad8ad0. [3] 刘涛, 李爱群. 准零刚度隔振系统的分析及研究进展[J]. 东南大学学报: 自然科学版, 2023, 53(6): 997–1012. doi: 10.3969/j.issn.1001-0505.2023.06.006.LIU Tao and LI Aiqun. An overview of research progress on quasi-zero stiffness vibration isolation systems[J]. Journal of Southeast University: Natural Science Edition, 2023, 53(6): 997–1012. doi: 10.3969/j.issn.1001-0505.2023.06.006. doi: 10.3969/j.issn.1001-0505.2023.06.006. [4] LI Xuan, DING Bingxiao, RAN Jinchao, et al. Design and characterization of a compact tripod quasi-zero-stiffness device for isolating low-frequency vibrations[J]. Precision Engineering, 2024, 91: 632–643. doi: 10.1016/j.precisioneng.2024.10.013. [5] MENG Qingye, HOU Lei, LIN Rongzhou, et al. Accurate nonlinear dynamic characteristics analysis of quasi-zero-stiffness vibration isolator via a modified incremental harmonic balance method[J]. Nonlinear Dynamics, 2024, 112(1): 125–150. doi: 10.1007/s11071-023-09036-y. [6] GATTI G. A nonlinear quasi-zero stiffness vibration isolator with quintic restoring force characteristic: A fundamental analytical insight[J]. Journal of Vibration and Control, 2024, 30(17/18): 4185–4198. doi: 10.1177/10775463231205806. [7] ZENG Rong, WEN Guilin, ZHOU Jiaxi, et al. Experimental investigation of a non-smooth quasi-zero-stiffness isolator[J]. Acta Mechanica Sinica, 2023, 39(6): 522415. doi: 10.1007/s10409-023-22415-x. [8] CARRELLA A, BRENNAN M J, WATERS T P, et al. Force and displacement transmissibility of a nonlinear isolator with high-static-low-dynamic-stiffness[J]. International Journal of Mechanical Sciences, 2012, 55(1): 22–29. doi: 10.1016/j.ijmecsci.2011.11.012. [9] 杨兆豪, 帅长庚, 李步云. 一种基于五弹簧模型的准零刚度隔振装置特性分析[J]. 舰船科学技术, 2023, 45(18): 77–84. doi: 10.3404/j.issn.1672-7649.2023.18.013.YANG Zhaohao, SHUAI Changgeng, and LI Buyun. Analysis of a five-spring vibration isolator with quasi-zero-stiffness characteristic[J]. Ship Science and Technology, 2023, 45(18): 77–84. doi: 10.3404/j.issn.1672-7649.2023.18.013. [10] 徐道临, 张月英, 周加喜, 等. 一种准零刚度隔振器的特性分析与实验研究[J]. 振动与冲击, 2014, 33(11): 208–213. doi: 10.13465/j.cnki.jvs.2014.11.036.XU Daolin, ZHANG Yueying, ZHOU Jiaxi, et al. Characteristic analysis and experimental investigation for a vibration isolator with quasi-zero stiffness[J]. Journal of Vibration and Shock, 2014, 33(11): 208–213. doi: 10.13465/j.cnki.jvs.2014.11.036. [11] YUN Hai, LIU Lei, LI Qing, et al. Investigation on two-stage vibration suppression and precision pointing for space optical payloads[J]. Aerospace Science and Technology, 2020, 96: 105543. doi: 10.1016/j.ast.2019.105543. [12] CAO J, LIU B, WU Q, et al. Research on the vibration control of micro-vibration using a novel hybrid isolator[J]. Experimental Techniques, 2024: 1–13. doi: 10.1007/S40799-024-00772-3. [13] SONG Henan, SHAN Xiaobiao, HOU Weijie, et al. A novel piezoelectric-based active-passive vibration isolator for low-frequency vibration system and experimental analysis of vibration isolation performance[J]. Energy, 2023, 278: 127870. doi: 10.1016/j.energy.2023.127870. [14] ZHU Wei, CHEN Gangli, and RUI Xiaoting. Modeling of piezoelectric stack actuators considering bonding layers[J]. Journal of Intelligent Material Systems and Structures, 2015, 26(17): 2418–2427. doi: 10.1177/1045389X15575083. [15] 姚晓成, 蒋春燕, 赵程, 等. 压电促动器的研制及其减振效果[J]. 机械工程材料, 2021, 45(6): 89–93. doi: 10.11973/jxgccl202106016.YAO Xiaocheng, JIANG Chunyan, ZHAO Cheng, et al. Fabrication and vibration reduction effect of piezoelectric actuator[J]. Materials for Mechanical Engineering, 2021, 45(6): 89–93. doi: 10.11973/jxgccl202106016. [16] YANG Liu, ZHONG Ruobing, LI Dongjie, et al. A fractional-order Duhem model of rate-dependent hysteresis for piezoelectric actuators[J]. Measurement and Control, 2022, 55(9/10): 974–982. doi: 10.1177/00202940221092140. [17] YANG Liu, CHENG Jiajia, HE He, et al. Cross-medium time-delay active vibration isolation method based on voltage-force hysteresis model[J]. Measurement, 2024, 235: 115027. doi: 10.1016/j.measurement.2024.115027. -

下载:

下载:

下载:

下载: