A Collaborative Detection Method for Bauxite Quality Parameters Based on the Fusion of G-DPN and Near-Infrared Spectroscopy

-

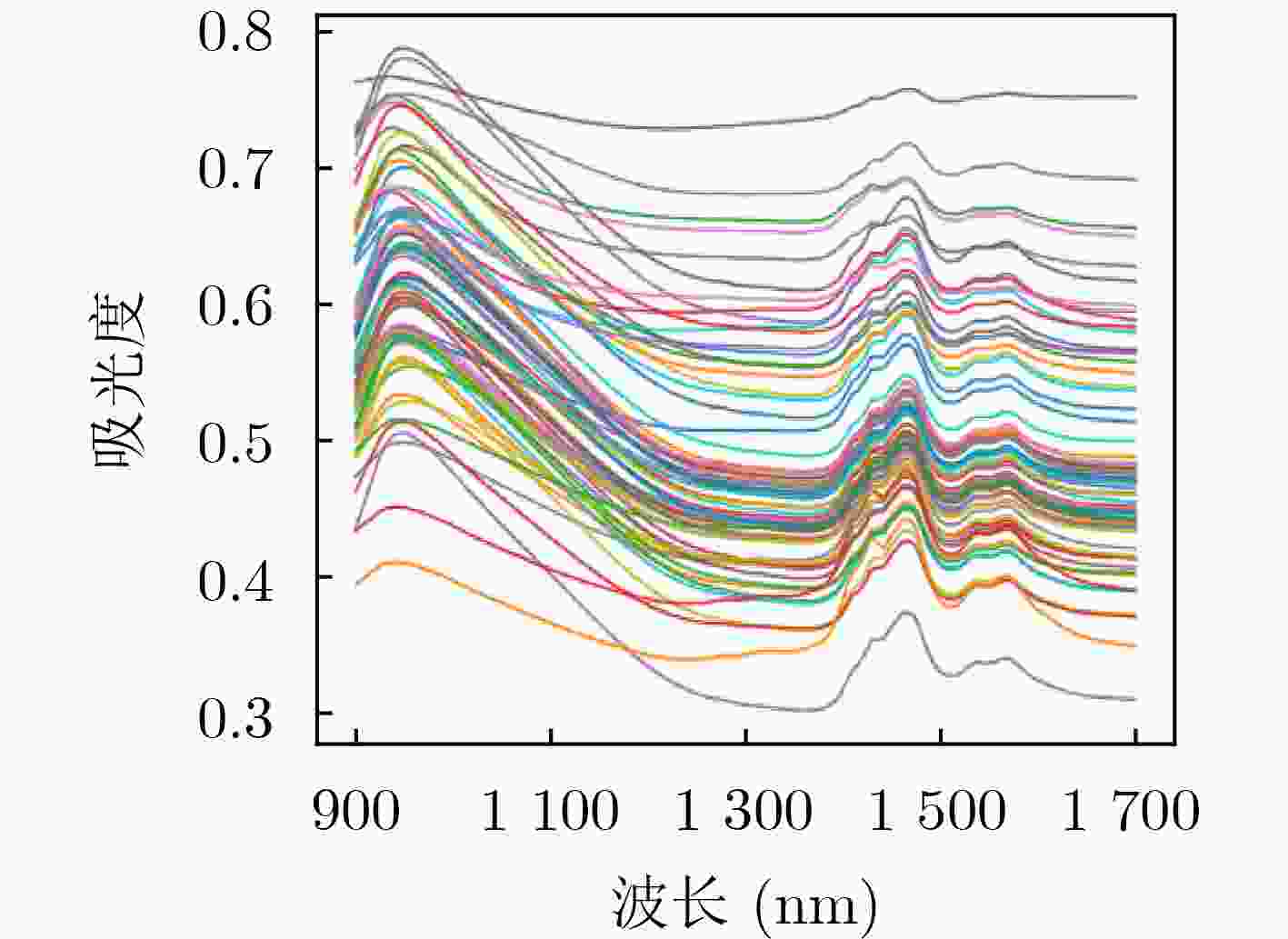

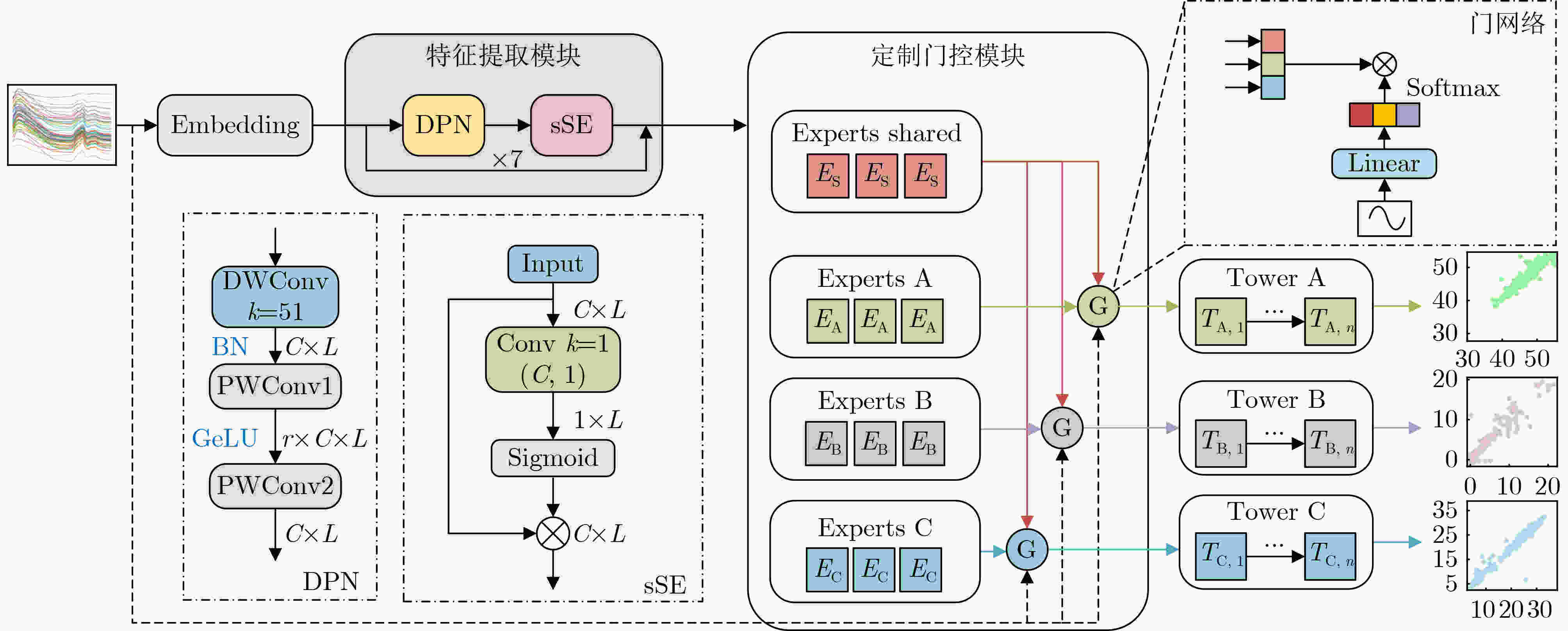

摘要: 铝矾土作为关键的非金属矿产资源,在铝工业等领域具有不可替代的作用。为实现资源高效利用并解决低品位矿石冶炼浪费问题,精确测定其品质参数至关重要。传统化学分析方法存在操作流程复杂、检测周期长、成本高昂等局限,而现有快检技术多聚焦单一参数预测,忽略参数间相关性。为此,该文提出一种基于近红外光谱的多指标协同检测模型——门控深度点卷积网络(G-DPN)。该模型创新性地采用大尺寸卷积核深度卷积提取单通道长距离相关特征,结合点卷积实现通道信息融合,并引入空间注意力机制强化关键特征表达能力。进一步设计定制门控模块,通过正交约束分离共享特征与任务特定特征,实现二者的动态加权融合,同时对参数标签归一化以消除量纲差异,有效构建光谱特征与品质参数间的非线性映射关系。基于424个铝矾土样本的实验表明,G-DPN在铝含量、硅含量和铁含量预测中的${R^2}$值分别达到

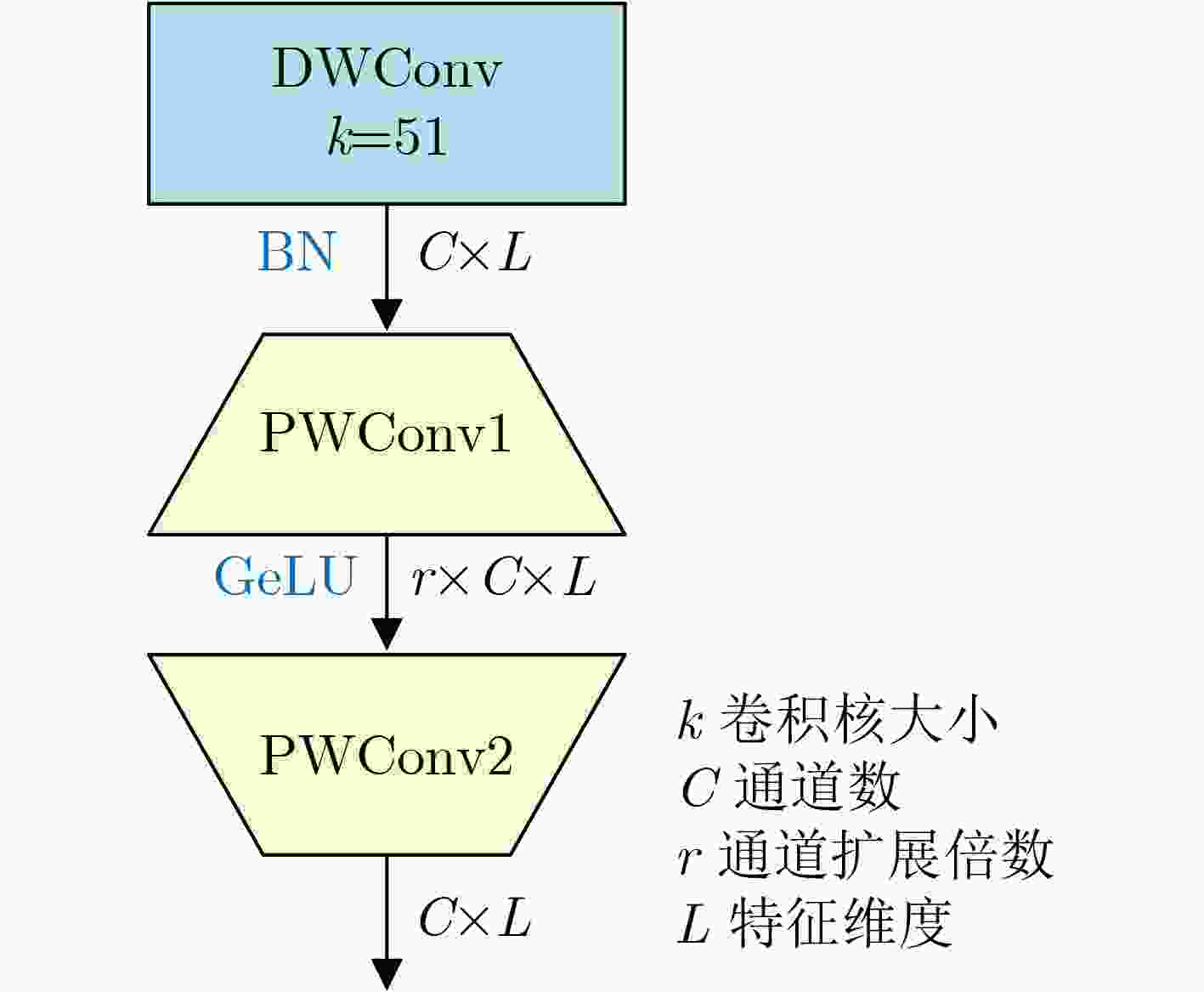

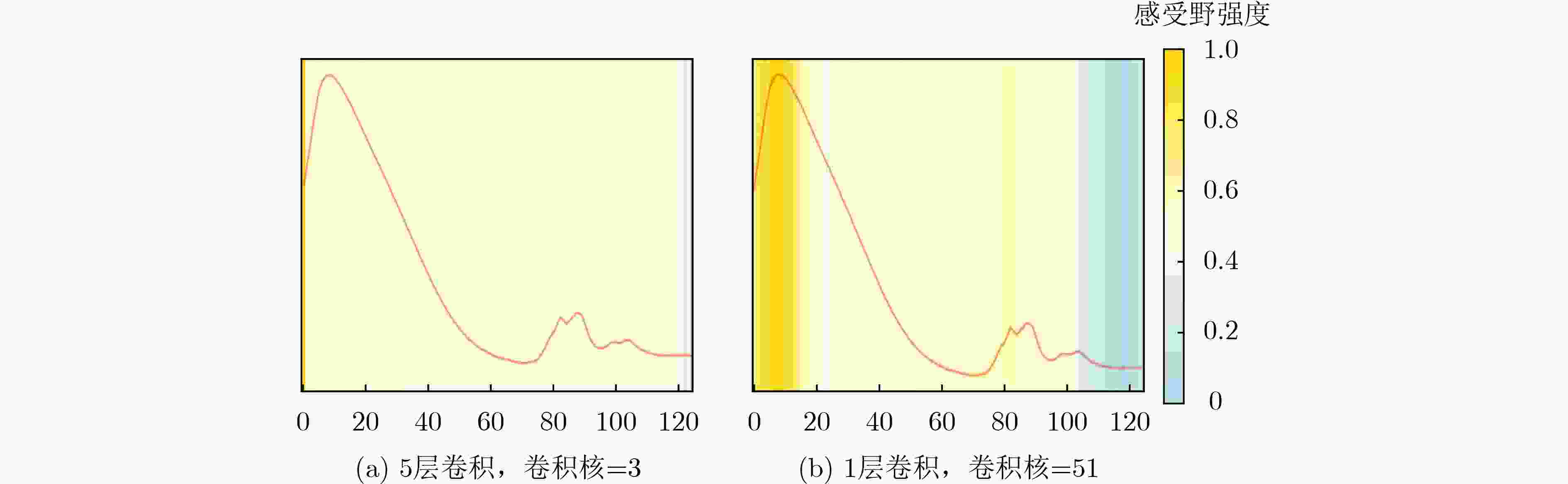

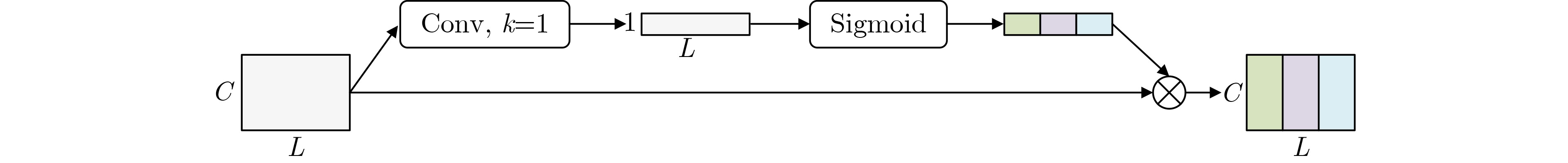

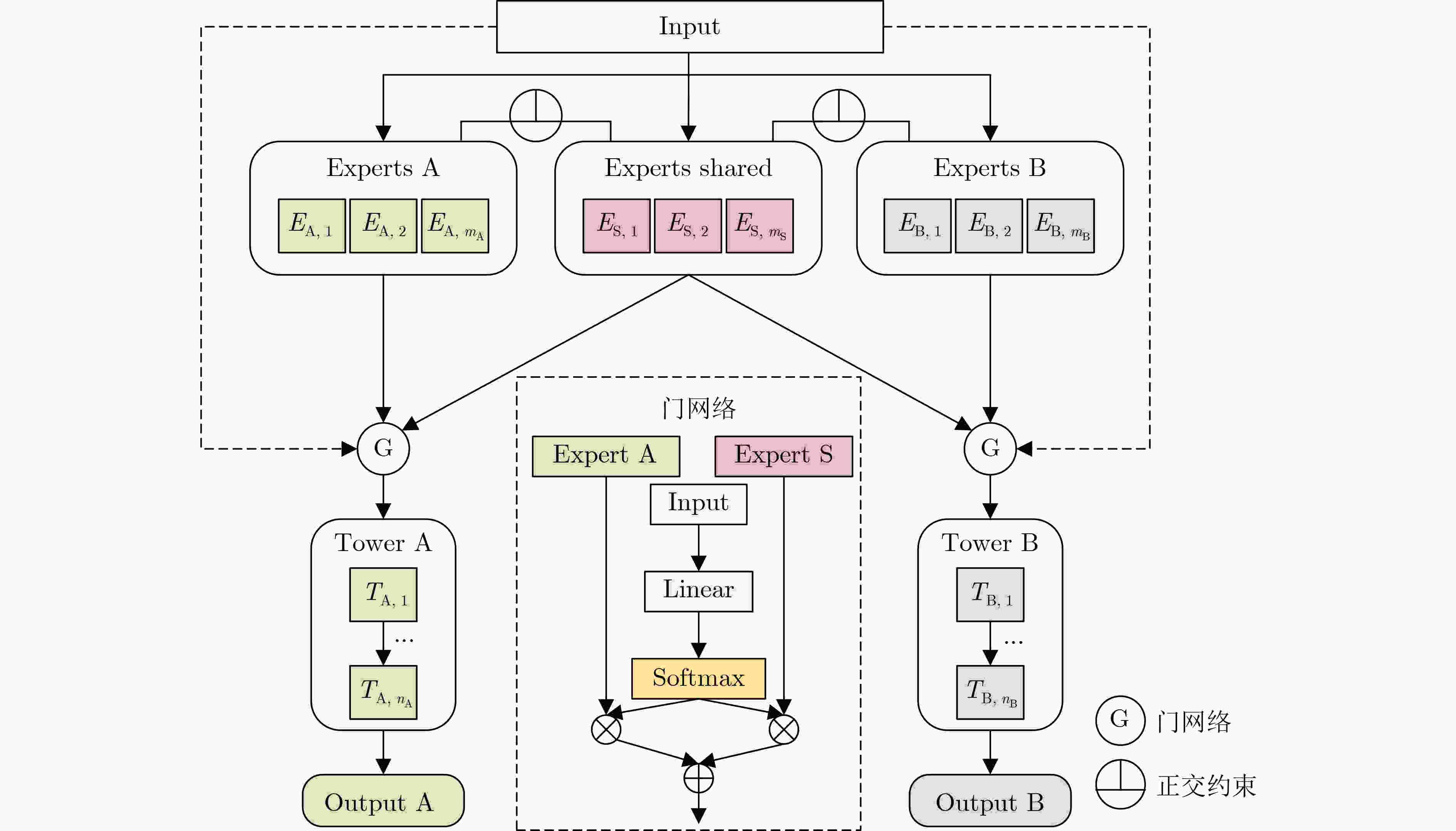

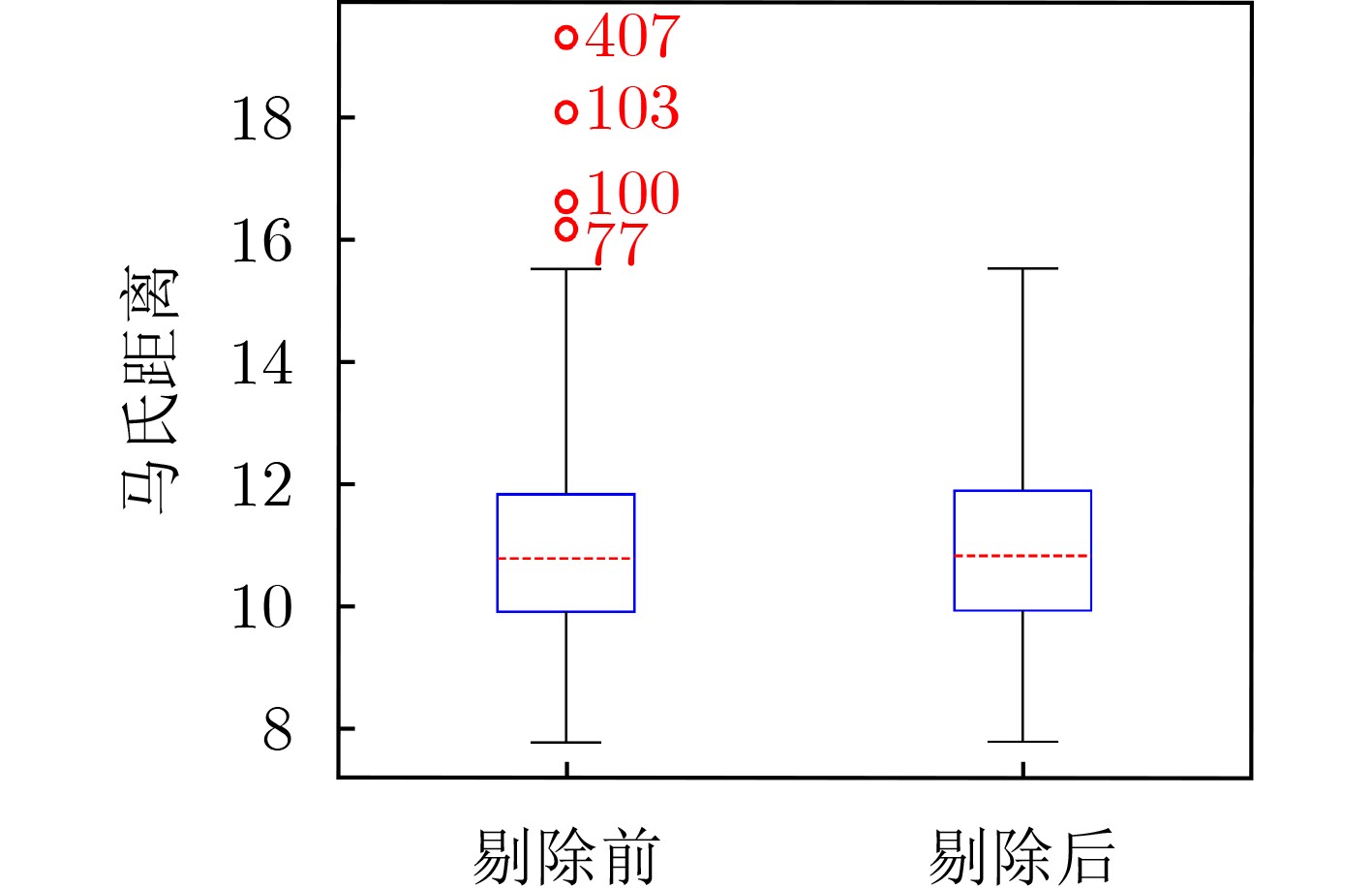

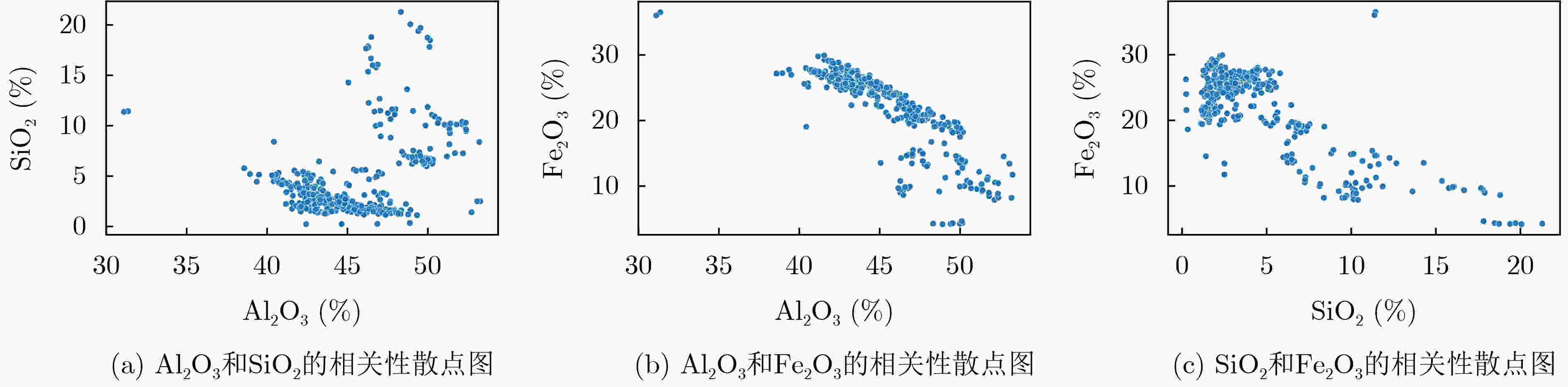

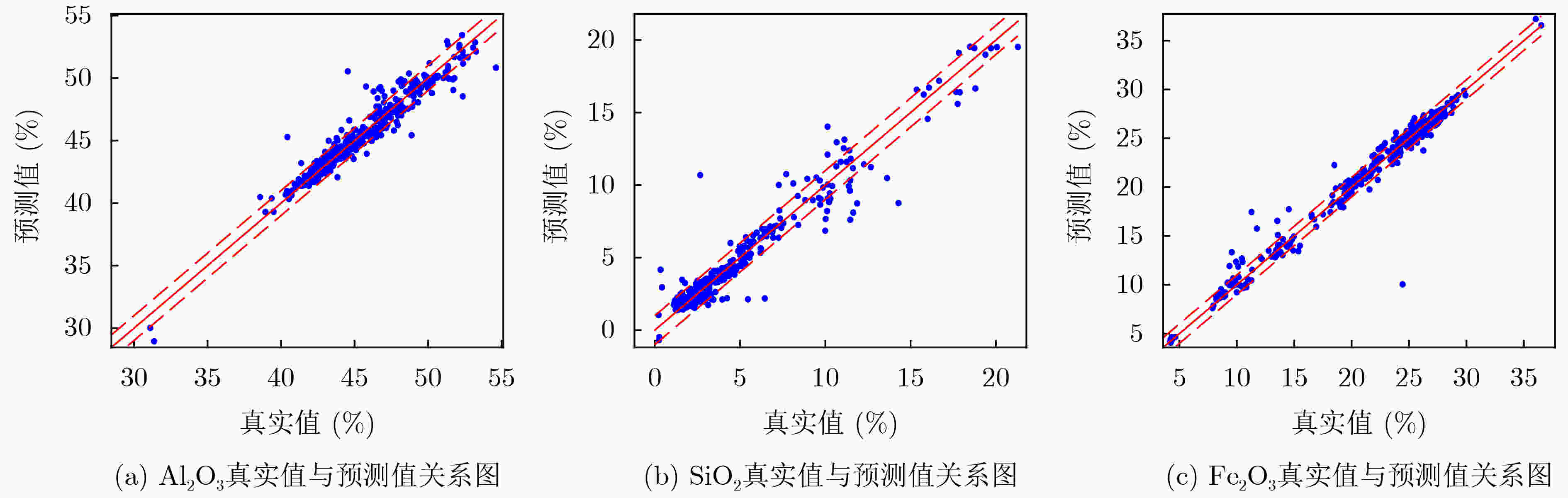

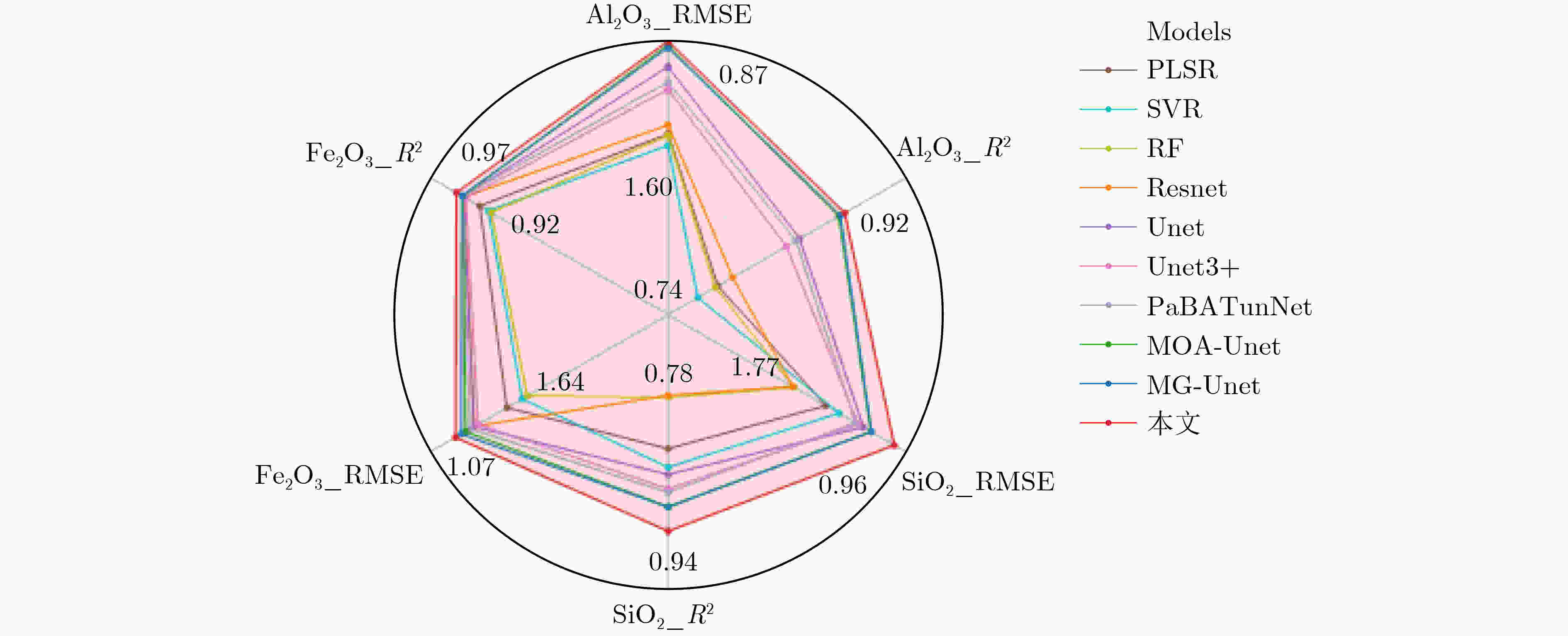

0.9226 ,0.9377 和0.9683 ,性能显著优于传统机器学习方法及多种深度学习模型。本研究证实近红外光谱技术结合G-DPN模型在铝矾土品质分析中具有显著应用价值,为矿产资源高效利用提供了新的技术支撑。Abstract:Objective Bauxite is a critical non-metallic mineral resource used in aluminum production, ceramic manufacturing, and refractory material processing. As global demand for aluminum and its derivatives continues to rise, improving the efficiency of bauxite resource utilization is essential. Accurate determination of quality parameters supports the reduction of waste from low-grade ores during smelting and improves overall process optimization. However, traditional chemical analyses are time-consuming, costly, complex, and subject to human error. Existing rapid testing methods, often based on machine learning, typically predict individual quality indicators and overlook correlations among multiple parameters. Deep learning, particularly multi-task learning, offers a solution to this limitation. Near-InfraRed (NIR) spectroscopy, a real-time, non-destructive analytical technique, is especially suited for assessing mineral quality. This study proposes a multi-indicator collaborative detection model—Gate-Depthwise Pointwise Network (G-DPN)—based on NIR spectroscopy to enable the simultaneous prediction of multiple bauxite quality parameters. The proposed approach addresses the limitations of conventional methods and supports efficient, accurate, and cost-effective real-time quality monitoring in industrial settings. Methods To accurately model the nonlinear relationships between NIR spectral features and bauxite quality parameters while leveraging inter-parameter correlations, this study proposes a dedicated representation model, G-DPN. The model incorporates large-kernel DepthWise Convolution (DWConv) to extract long-range dependencies within individual spectral channels, and PointWise Convolution (PWConv) to enable inter-channel feature fusion. A Spatial Squeeze-and-Excitation (sSE) mechanism is introduced to enhance spatial feature weighting, and residual connections support the integration of deep features. To further improve task differentiation, a Custom Gate Control (CGC) module is added to separate shared and task-specific features. Orthogonal constraints are applied within this module to reduce feature redundancy. Gate-controlled fusion enables each branch to focus on extracting task-relevant information while preserving shared representations. Additionally, quality parameter labels are normalized to address scale heterogeneity, allowing the model to establish a stable nonlinear mapping between spectral inputs and multiple output parameters. Results and Discussions This study applies large convolution kernels in DWConv to capture long-range dependencies within individual spectral channels ( Fig. 3 ). Compared with conventional small-sized kernels (e.g., 3×3), which increase the receptive field but exhibit limited focus on critical spectral regions, large kernels enable more concentrated activation in key bands, thereby enhancing model sensitivity (Fig. 4 ). Empirical results confirm that the use of large kernels improves prediction accuracy (Table 6 ). Furthermore, compared to Transformer-based models, DWConv with large kernels achieves comparable accuracy with fewer parameters, offering computational efficiency. The CGC module effectively disentangles shared and task-specific features while applying orthogonal constraints to reduce redundancy. Its dynamic fusion mechanism enables adaptive feature sharing across tasks without compromising task-specific learning, thereby mitigating task interference and accounting for sample correlations (Fig. 6 ). Relative to conventional multi-task learning frameworks, the CGC-based architecture demonstrates superior performance in multi-parameter prediction (Table 6 ).Conclusions This study proposes a deep learning approach that integrates large-kernel DWConv and a CGC module for multi-parameter prediction of bauxite quality using NIR spectroscopy. DWConv captures long-range dependencies within spectral channels, while the CGC module leverages inter-parameter correlations to enhance feature sharing and reduce task interference. This design mitigates the effects of spectral peak overlap and establishes a robust nonlinear mapping between spectral features and quality parameters. Experiments on 424 bauxite samples show that the proposed G-DPN model achieves ${R^2}$ values of 0.9226 ,0.9377 , and0.9683 for aluminum, silicon, and iron content, respectively—outperforming conventional machine learning and existing deep learning methods. These results highlight the potential of combining NIR spectroscopy with G-DPN for accurate, efficient, and scalable mineral quality analysis, contributing to the sustainable utilization of bauxite resources. -

表 1 实验与样本分布参数

项目 描述 样本处理 干燥、破碎、研磨、筛分 样本粒径 0.15 mm Al2O3含量(%) 31.1~54.62 SiO2含量(%) 0.23~21.29 Fe2O3含量(%) 4.19~36.52 表 2 PLSR在异常值剔除后的5折交叉验证平均结果分析

成分指标 方法 RMSE MAE ${R^2}$ Al2O3(%) / 1.5718 1.0872 0.7490 马氏距离 1.5160 1.0190 0.7630 SiO2(%) / 1.6072 0.9960 0.8246 马氏距离 1.5044 0.9232 0.8472 Fe2O3(%) / 1.7195 1.0145 0.9174 马氏距离 1.4770 0.9148 0.9387 表 3 PLSR结合SNV的5折交叉验证平均结果分析

成分指标 方法 RMSE MAE ${R^2}$ Al2O3(%) / 1.6592 1.1513 0.7161 SNV 1.5160 1.0190 0.7630 SiO2(%) / 1.9353 1.2899 0.7471 SNV 1.5044 0.9232 0.8472 Fe2O3(%) / 1.5277 0.9836 0.9344 SNV 1.4770 0.9148 0.9387 表 4 传统机器学习模型与本研究方法结果对比

成分指标 方法 RMSE±std MAE±std ${R^2}$±std Al2O3(%) PLSR 1.5160 ±0.0411 1.0190 ±0.0456 0.7630 ±0.0132 SVR 1.5950 ±0.0792 0.9998 ±0.0205 0.7376 ±0.0271 RF 1.5261 ±0.0963 0.8722 ±0.0269 0.7598 ±0.0292 本文 0.8729 ±0.0501 0.5638 ±0.0085 0.9226 ±0.0080 SiO2(%) PLSR 1.5044 ±0.0354 0.9232 ±0.0371 0.8472 ±0.0088 SVR 1.4004 ±0.0486 0.7628 ±0.0248 0.8676 ±0.0092 RF 1.7592 ±0.0766 0.8854 ±0.0410 0.7910 ±0.0168 本文 0.9582 ±0.0251 0.5455 ±0.0110 0.9377 ±0.0034 Fe2O3(%) PLSR 1.4770 ±0.0573 0.9148 ±0.0331 0.9387 ±0.0051 SVR 1.5999 ±0.0538 0.8944 ±0.0119 0.9280 ±0.0054 RF 1.6394 ±0.0823 0.7967 ±0.0201 0.9244 ±0.0072 本文 1.0655 ±0.0291 0.5557 ±0.0077 0.9683 ±0.0017 表 5 深度学习模型与本研究方法结果比较

成分指标 方法 RMSE±std MAE±std ${R^2}$±std Al2O3(%) ResNet 1.4541 ±0.1267 1.1057 ±0.0709 0.7819 ±0.0435 Unet 1.0497 ±0.0795 0.5330 ±0.0243 0.8666 ±0.0152 Unet3+ 1.2069 ±0.1867 0.5827 ±0.0424 0.8498 ±0.0389 PaBATunNet 1.1558 ±0.0438 0.8126 ±0.0423 0.8620 ±0.0106 MOA-Unet 0.9002 ±0.0536 0.5511 ±0.0175 0.9161 ±0.0099 MG-Unet 0.9182 ±0.0579 0.5617 ±0.0099 0.9181 ±0.0104 本文 0.8729 ±0.0501 0.5638 ±0.0085 0.9226 ±0.0080 SiO2(%) ResNet 1.7682 ±0.1056 1.1041 ±0.0644 0.7889 ±0.0276 Unet 1.2057 ±0.0937 0.5798 ±0.0377 0.8756 ±0.0141 Unet3+ 1.2460 ±0.1167 0.6128 ±0.0424 0.8952 ±0.0191 PaBATunNet 1.2685 ±0.0339 0.7252 ±0.0242 0.8912 ±0.0058 MOA-Unet 1.1463 ±0.0605 0.6171 ±0.0258 0.9107 ±0.0094 MG-Unet 1.1416 ±0.0740 0.6063 ±0.0248 0.9112 ±0.0132 本文 0.9582 ±0.0251 0.5455 ±0.0110 0.9377 ±0.0034 Fe2O3(%) ResNet 1.2153 ±0.1795 0.8534 ±0.0965 0.9585 ±0.0160 Unet 1.2518 ±0.1274 0.5613 ±0.0398 0.9596 ±0.0082 Unet3+ 1.2466 ±0.1087 0.5373 ±0.0280 0.9563 ±0.0072 PaBATunNet 1.1840 ±0.0195 0.7347 ±0.0217 0.9605 ±0.0018 MOA-Unet 1.1466 ±0.0815 0.5729 ±0.0236 0.9632 ±0.0052 MG-Unet 1.1116 ±0.0603 0.5578 ±0.0297 0.9653 ±0.0037 本文 1.0655 ±0.0291 0.5557 ±0.0077 0.9683 ±0.0017 表 6 消融实验

成分指标 方法 RMSE MAE ${R^2}$ Al2O3(%) DPN(k=3) 1.0859 0.6466 0.8783 DPN(k=51) 0.9866 0.5887 0.8996 DPN+sSE 0.9738 0.5777 0.9022 DPN+sSE+多任务 0.9533 0.5763 0.9063 DPN+sSE+CGC 0.8729 0.5638 0.9226 SiO2(%) DPN(k=3) 1.1657 0.6566 0.9082 DPN(k=51) 1.1114 0.5905 0.9165 DPN+sSE 1.0670 0.5672 0.9231 DPN+sSE+多任务 1.0488 0.5599 0.9257 DPN+sSE+CGC 0.9582 0.5455 0.9377 Fe2O3(%) DPN(k=3) 1.2885 0.6835 0.9533 DPN(k=51) 1.1423 0.5679 0.9633 DPN+sSE 1.1420 0.5805 0.9633 DPN+sSE+多任务 1.0734 0.5673 0.9674 DPN+sSE+CGC 1.0655 0.5557 0.9683 -

[1] LYU Fei, HU Yuehua, WANG Li, et al. Dealkalization processes of bauxite residue: A comprehensive review[J]. Journal of Hazardous Materials, 2021, 403: 123671. doi: 10.1016/j.jhazmat.2020.123671. [2] ZHOU Guotao, WANG Yilin, QI Tiangui, et al. Toward sustainable green alumina production: A critical review on process discharge reduction from gibbsitic bauxite and large-scale applications of red mud[J]. Journal of Environmental Chemical Engineering, 2023, 11(2): 109433. doi: 10.1016/j.jece.2023.109433. [3] CHAO Xi, ZHANG Ting’an, LV Guozhi, et al. Comprehensive application technology of bauxite residue treatment in the ecological environment: A review[J]. Bulletin of Environmental Contamination and Toxicology, 2022, 109(1): 209–214. doi: 10.1007/s00128-022-03478-7. [4] KAR M K, ӦNAL M A R, and BORRA C R. Alumina recovery from bauxite residue: A concise review[J]. Resources, Conservation and Recycling, 2023, 198: 107158. doi: 10.1016/j.resconrec.2023.107158. [5] WU Lin, ZHANG Jie, HUANG Zhilong, et al. Extraction of lithium as lithium phosphate from bauxite mine tailings via mixed acid leaching and chemical precipitation[J]. Ore Geology Reviews, 2023, 160: 105621. doi: 10.1016/j.oregeorev.2023.105621. [6] DE AZEVEDO A R G, MARVILA M T, DE OLIVEIRA M A B, et al. Perspectives for the application of bauxite wastes in the development of alternative building materials[J]. Journal of Materials Research and Technology, 2022, 20: 3114–3125. doi: 10.1016/j.jmrt.2022.08.092. [7] HARMON R S. Laser-induced breakdown spectroscopy in mineral exploration and ore processing[J]. Minerals, 2024, 14(7): 731. doi: 10.3390/min14070731. [8] MASSOUD A, ABDOU F S, and YOUSIF M. Evaluation of mineral compositions of surface and subsurface rock samples by neutron activation analysis[J]. International Journal of Environmental Analytical Chemistry, 2023, 103(3): 528–545. doi: 10.1080/03067319.2020.1862095. [9] TSUCHIKAWA S, MA Te, and INAGAKI T. Application of near-infrared spectroscopy to agriculture and forestry[J]. Analytical Sciences, 2022, 38(4): 635–642. doi: 10.1007/s44211-022-00106-6. [10] 黄志伟, 郭拓, 黄文静, 等. 近红外光谱技术在名贵中药材质量评价中的研究进展[J]. 中草药, 2022, 53(20): 6328–6336. doi: 10.7501/j.issn.0253-2670.2022.20.003.HUANG Zhiwei, GUO Tuo, HUANG Wenjing, et al. Research progress of near-infrared spectroscopy in quality evaluation of valuable Chinese medicinal materials[J]. Chinese Traditional and Herbal Drugs, 2022, 53(20): 6328–6336. doi: 10.7501/j.issn.0253-2670.2022.20.003. [11] 李敬岩, 褚小立, 陈瀑, 等. 化学计量学赋能现代光谱分析技术—理论、仪器和应用进展[J]. 冶金分析, 2024, 44(10): 1–9. doi: 10.13228/j.boyuan.issn1000-7571.012513.LI Jingyan, CHU Xiaoli, CHEN Pu, et al. Modern spectral analysis technology empowered by chemometrics: Theory, instrument and application progress[J]. Metallurgical Analysis, 2024, 44(10): 1–9. doi: 10.13228/j.boyuan.issn1000-7571.012513. [12] ZHANG Wenwen, KASUN L C, WANG Qijie, et al. A review of machine learning for near-infrared spectroscopy[J]. Sensors, 2022, 22(24): 9764. doi: 10.3390/s22249764. [13] CARVALHO J K, MOURA-BUENO J M, RAMON R, et al. Combining different pre-processing and multivariate methods for prediction of soil organic matter by near infrared spectroscopy (NIRS) in Southern Brazil[J]. Geoderma Regional, 2022, 29: e00530. doi: 10.1016/j.geodrs.2022.e00530. [14] AMSARAJ R and MUTTURI S. Support vector machine-based rapid detection and quantification of butter yellow adulteration in mustard oil using NIR spectra[J]. Infrared Physics & Technology, 2023, 129: 104543. doi: 10.1016/j.infrared.2023.104543. [15] 翁士状, 储昭结, 王满琴, 等. 反射光谱结合光谱基二维卷积回归网络快速检测食用油中饱和脂肪酸[J]. 光谱学与光谱分析, 2022, 42(5): 1490–1496. doi: 10.3964/j.issn.1000-0593(2022)05-1490-07.WENG Shizhuang, CHU Zhaojie, WANG Manqin, et al. Reflectance spectroscopy for accurate and fast analysis of saturated fatty acid of edible oil using spectroscopy-based 2D convolution regression network[J]. Spectroscopy and Spectral Analysis, 2022, 42(5): 1490–1496. doi: 10.3964/j.issn.1000-0593(2022)05-1490-07. [16] YUAN Quan, WANG Jiajun, ZHENG Mingwei, et al. Hybrid 1D-CNN and attention-based Bi-GRU neural networks for predicting moisture content of sand gravel using NIR spectroscopy[J]. Construction and Building Materials, 2022, 350: 128799. doi: 10.1016/j.conbuildmat.2022.128799. [17] HE Tianyu, SHI Yabo, CUI Enzhong, et al. Rapid detection of multi-indicator components of classical famous formula Zhuru Decoction concentration process based on fusion CNN-LSTM hybrid model with the near-infrared spectrum[J]. Microchemical Journal, 2023, 195: 109438. doi: 10.1016/j.microc.2023.109438. [18] ZHANG Yu and YANG Qiang. A survey on multi-task learning[J]. IEEE Transactions on Knowledge and Data Engineering, 2022, 34(12): 5586–5609. doi: 10.1109/tkde.2021.3070203. [19] ZOU Liang, YU Xinhui, LI Ming, et al. Nondestructive identification of coal and gangue via near-infrared spectroscopy based on improved broad learning[J]. IEEE Transactions on Instrumentation and Measurement, 2020, 69(10): 8043–8052. doi: 10.1109/tim.2020.2988169. [20] DING Xiaohan, ZHANG Xiangyu, HAN Jungong, et al. Scaling up your kernels to 31×31: Revisiting large kernel design in CNNs[C]. The 2022 IEEE/CVF Conference on Computer Vision and Pattern Recognition, New Orleans, USA, 2022: 11953–11965. doi: 10.1109/cvpr52688.2022.01166. [21] LUO Donghao and WANG Xue. ModernTCN: A modern pure convolution structure for general time series analysis[C]. The Twelfth International Conference on Learning Representations, Vienna, Austria, 2024. [22] XU Shifan, XU Zhibin, ZHENG Jiannan, et al. Where does the crude oil originate? The role of near-infrared spectroscopy in accurate source detection[J]. Memetic Computing, 2024, 16(3): 429–443. doi: 10.1007/s12293-024-00425-3. [23] TANG Hongyan, LIU Junning, ZHAO Ming, et al. Progressive Layered Extraction (PLE): A novel Multi-task learning (MTL) model for personalized recommendations[C]. The 14th ACM Conference on Recommender Systems, Virtual Event, Brazil, 2020: 269–278. doi: 10.1145/3383313.3412236. [24] ZOU Liang, QIAO Jiahui, YU Xinhui, et al. Intelligent proximate analysis of coal based on near-infrared spectroscopy and multioutput deep learning[J]. IEEE Transactions on Artificial Intelligence, 2024, 5(3): 1398–1410. doi: 10.1109/tai.2023.3296714. [25] YU Shui, HUAN Kewei, LIU Xiaoxi, et al. Quantitative model of near infrared spectroscopy based on pretreatment combined with parallel convolution neural network[J]. Infrared Physics & Technology, 2023, 132: 104730. doi: 10.1016/j.infrared.2023.104730. -

下载:

下载:

下载:

下载: