A Domain Adaptive Method with Orthogonal Constraint for Predicting the Remaining Useful Life of Rolling Bearings under Cross Working Conditions

-

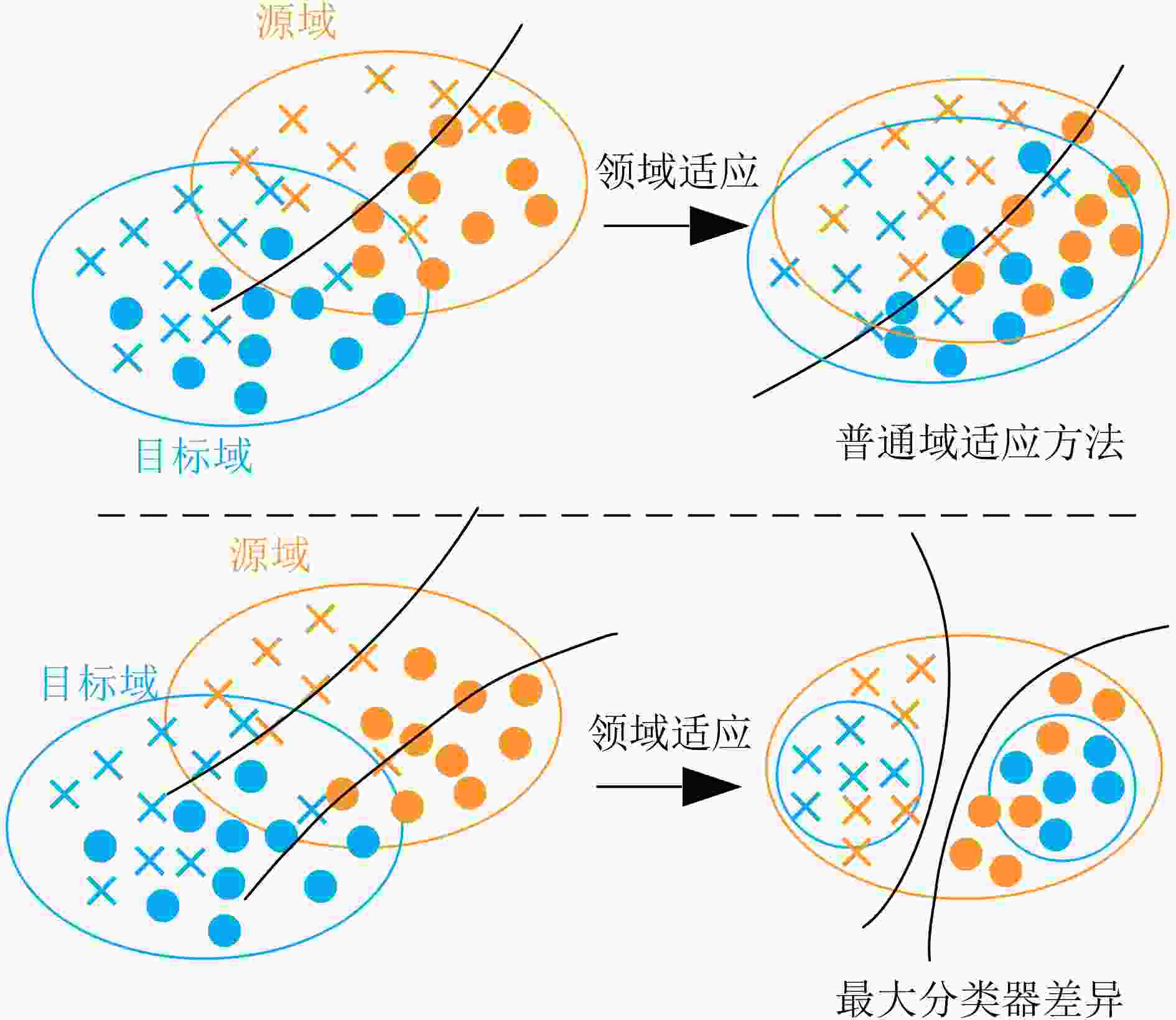

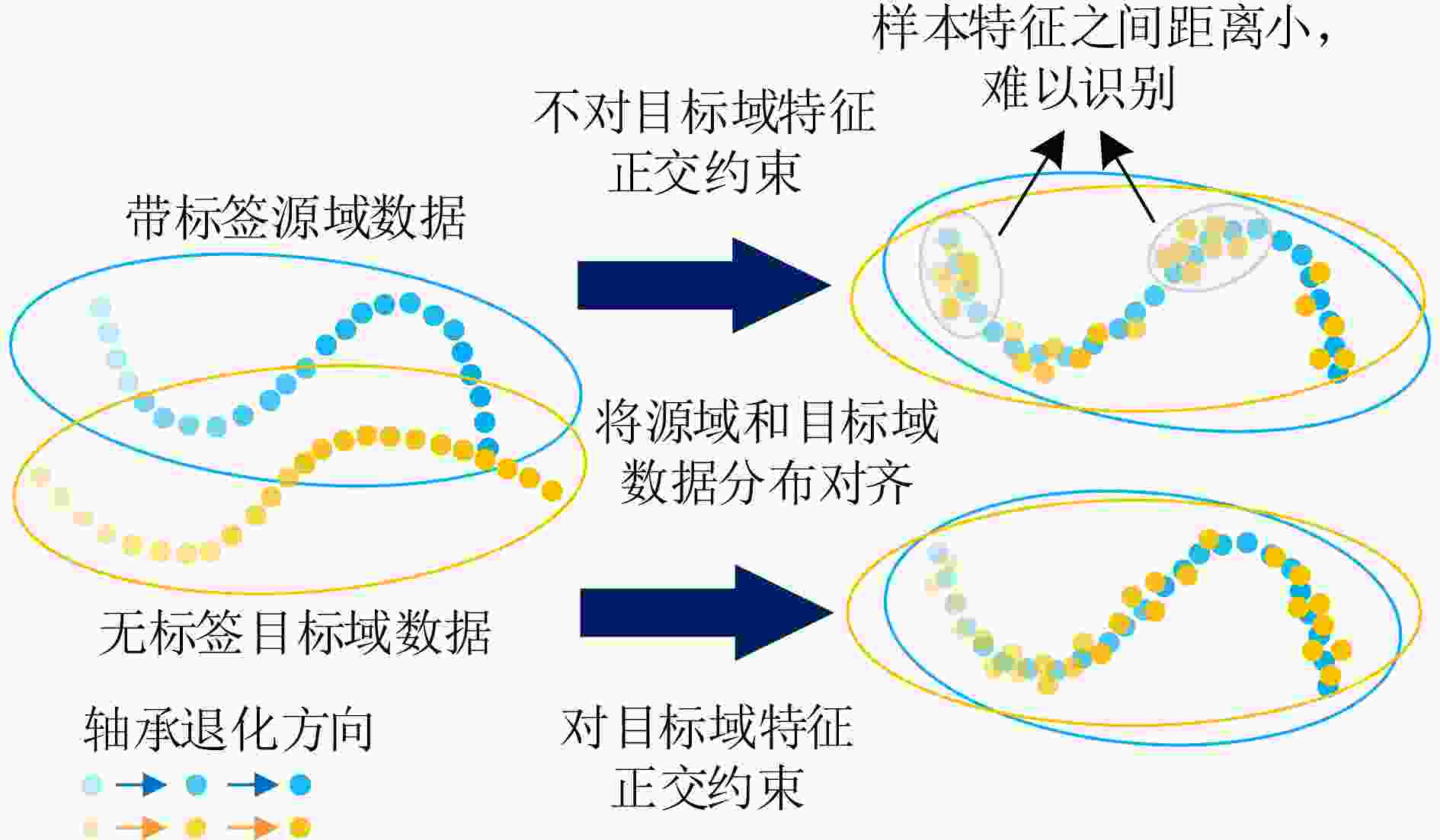

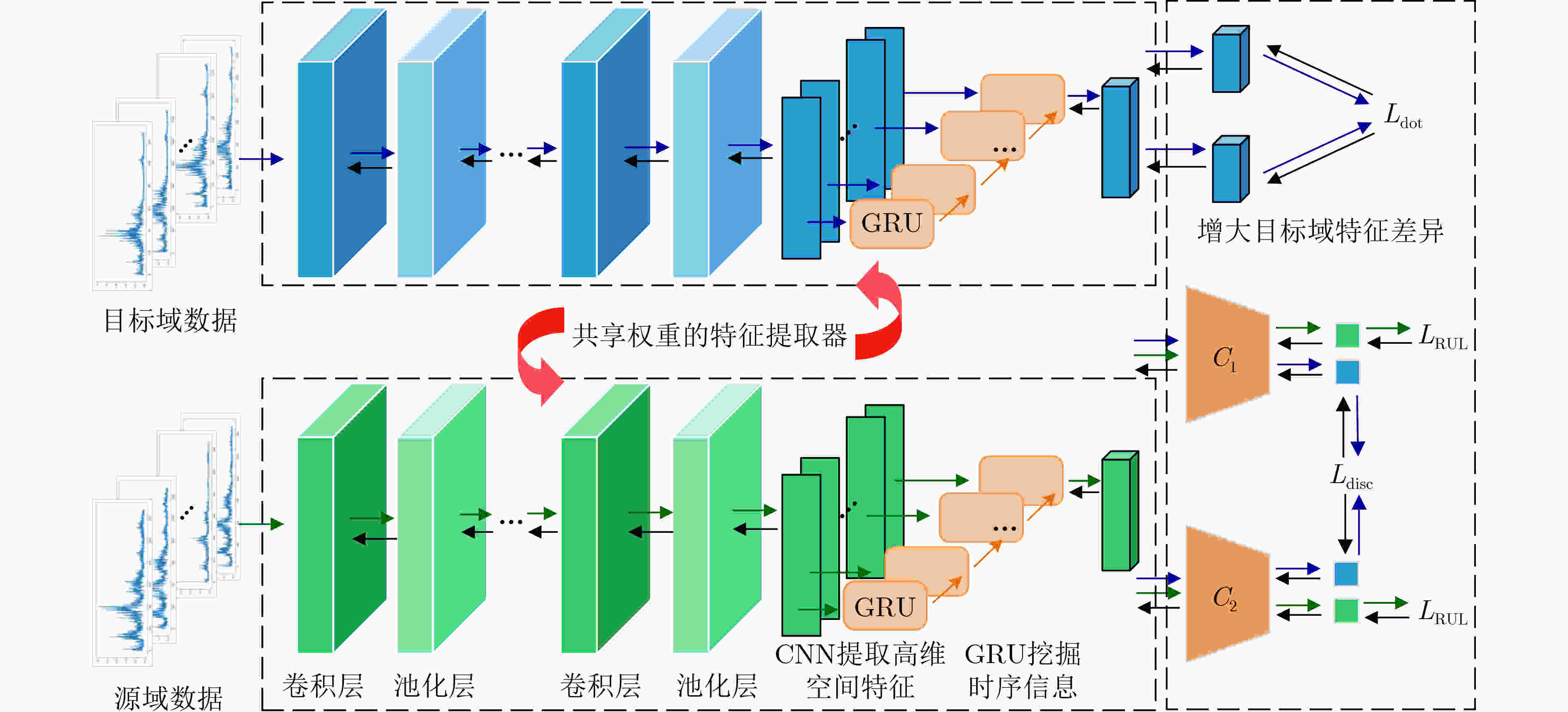

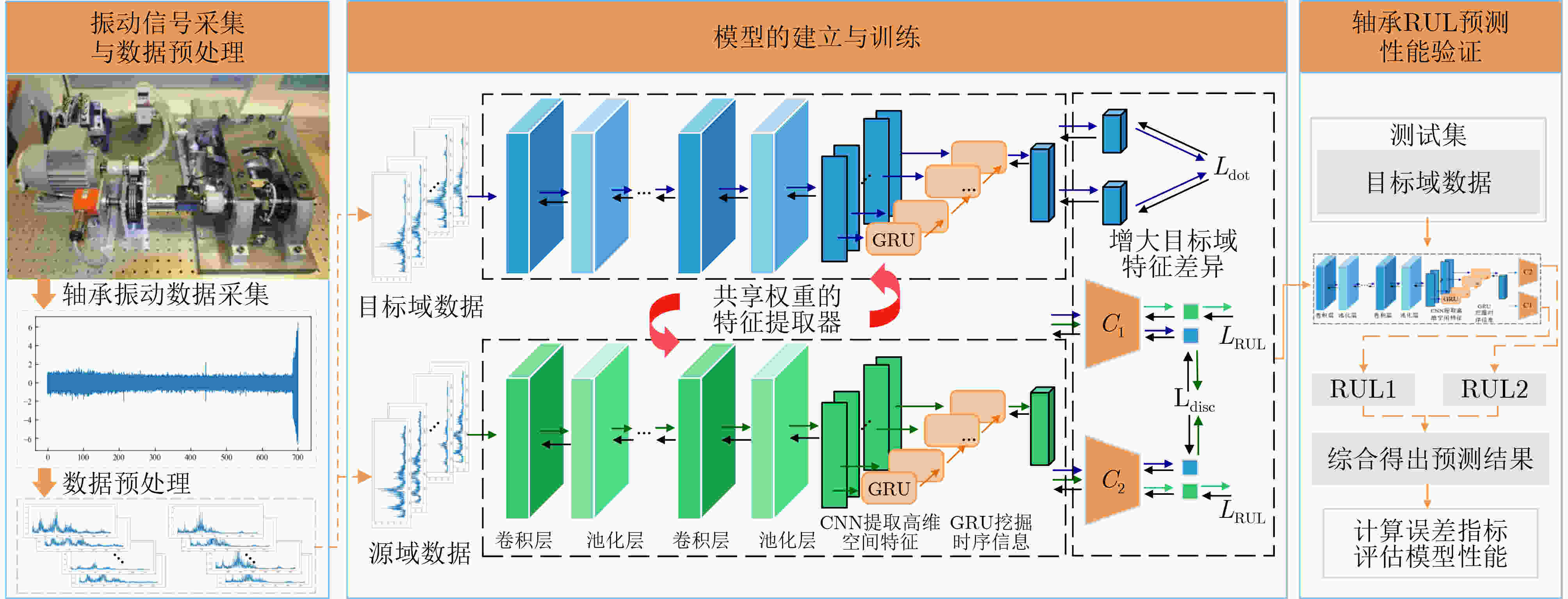

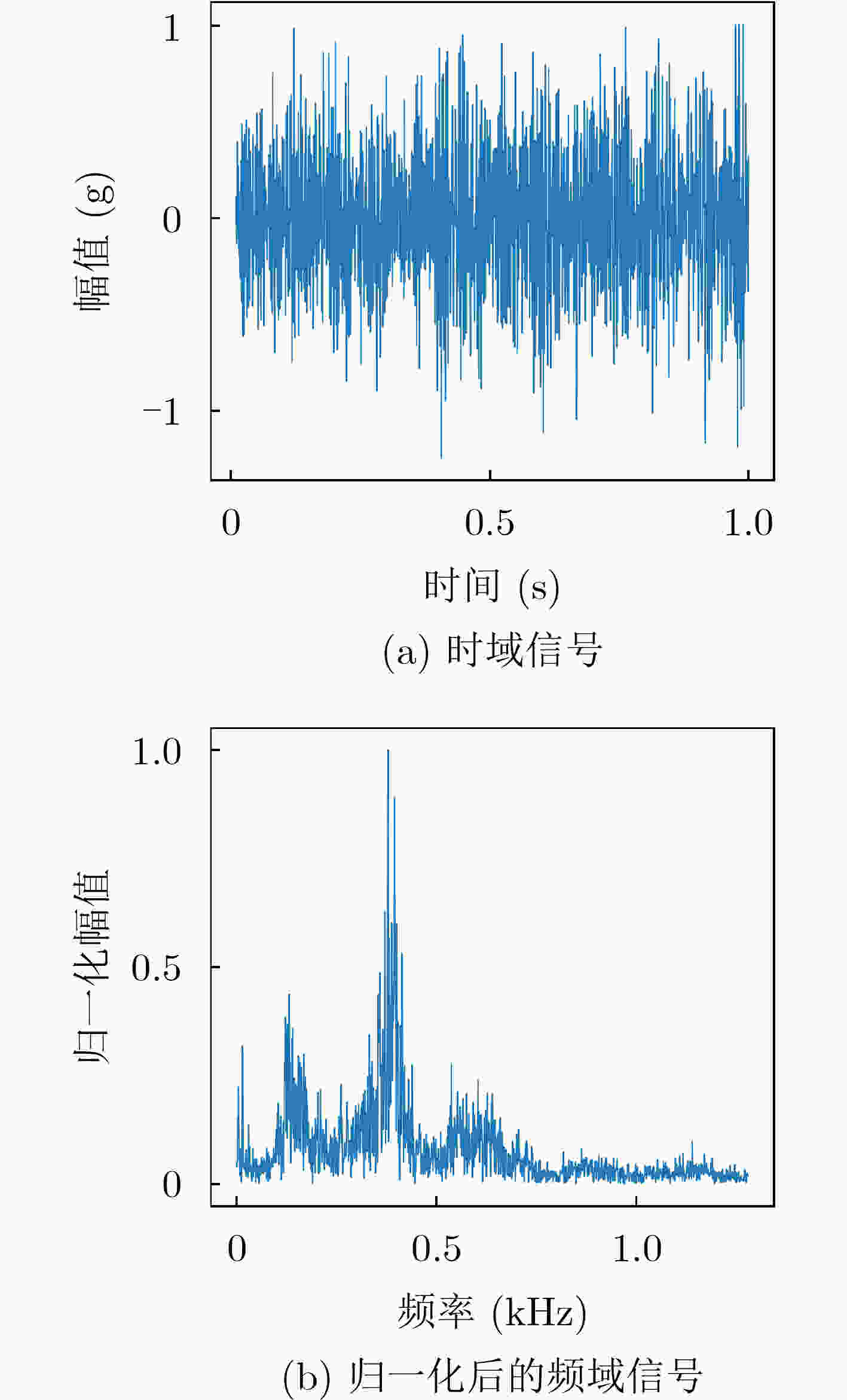

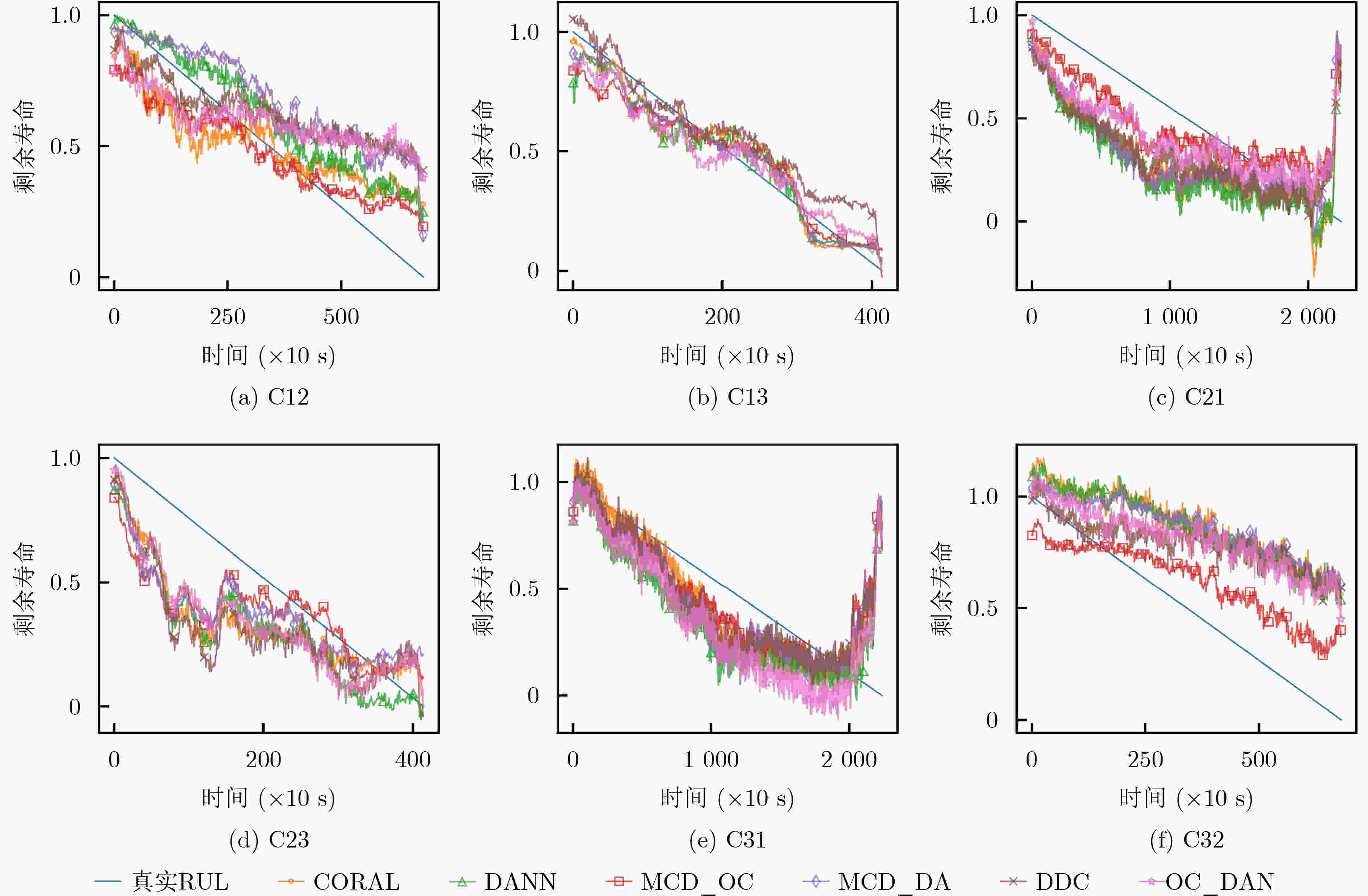

摘要: 针对跨工况轴承剩余使用寿命(RUL)预测模型的决策边界不明显、特征可辨识性低的问题,该文提出一种正交约束的最大分类器差异方法(MCD_OC)。首先,将采集的轴承原始振动信号进行快速傅里叶变换,得到振动信号的频域信号作为模型的输入;然后,通过卷积神经网络(CNN)和门控循环神经网络(GRU)提取轴承信号的深层时空特征,利用最大分类器差异将源域和目标域特征对齐,并对目标域轴承深层特征进行正交约束,增大无标签目标域样本特征之间的可辨识性;最后,基于轴承寿命数据集开展了跨工况轴承寿命预测对比实验,对该文所提方法进行评估,并在多组实验中取得最优结果。Abstract: To address the problems that blurred decision boundaries and low identifiability of features in the rolling bearing Remaining Useful Life (RUL) prediction under cross working conditions, a domain adaptive method with Maximum Classifier Discrepancy network with Orthogonal Constraints (MCD_OC) is proposed. Firstly, the fast Fourier transform is applied to transform the raw vibration signal into the frequency domain signal and input it to the model. Then, Convolutional Neural Network (CNN) and Gate Recurrent Unit (GRU) are used to extract the depth spatiotemporal features of the bearing signal, the source and target domain feature is aligned using the maximum classifier discrepancy, and the orthogonal constraint is applied to constrain target domain features to increase the identifiability between features of unlabeled target domain feature. Finally, comparative experiments are conducted on the prediction of cross working condition RUL predict based on the bearing life dataset to evaluate the method in this work, and the optimal results are obtained in multiple experiments.

-

表 1 轴承运行的3种不同工况

变量 工况1 工况2 工况3 压力(N) 4000 4200 5000 转速(r/min) 1800 1650 1500 表 2 MCD_OC试验数据集

任务 源域训练集 目标域训练集 测试集 工况1→工况2(C12) 轴承1-1~1-7 轴承2-1,2-2 轴承2-6 工况1→工况3(C13) 轴承1-1~1-7 轴承3-1,3-2 轴承3-3 工况2→工况1(C21) 轴承2-1~2-7 轴承1-1,1-2 轴承1-7 工况2→工况3(C23) 轴承2-1~2-7 轴承3-1,3-2 轴承3-3 工况3→工况1(C31) 轴承3-1~3-3 轴承1-1,1-2 轴承1-7 工况3→工况2(C32) 轴承3-1~3-3 轴承2-1,2-2 轴承2-6 表 3 模型参数

网络层 参数 激活函数 卷积层1, BN 卷积核大小7×1,数量 80,步长1 ReLU 最大池化层1 大小 8×1,步长8 \ 卷积层2, BN 卷积核大小5×1,数量160,步长1 ReLU 最大池化层2 大小8×1,步长1 \ 卷积层3, BN 卷积核大小3×1,数量 320,步长1 ReLU 最大池化层3 大小4×1,步长1 \ GRU 输出维度 1440 \ 全连接层1 神经元个数128,Dropout 0.5 \ 全连接层2 神经元个数32,Dropout 0.5 \ 全连接层3 神经元个数1 \ 表 4 MCD_OC和对比模型的预测结果

方法 评价指标 C12 C13 C21 C23 C31 C32 平均值 DDC MAE 0.179 0.118 0.224 0.212 0.160 0.307 0.200 RMSE 0.218 0.136 0.258 0.246 0.208 0.354 0.237 DANN MAE 0.120 0.070 0.271 0.227 0.166 0.413 0.211 RMSE 0.149 0.092 0.311 0.257 0.213 0.442 0.244 CORAL MAE 0.146 0.065 0.230 0.198 0.162 0.414 0.202 RMSE 0.167 0.080 0.269 0.238 0.234 0.435 0.237 DDC_OC MAE 0.174 0.080 0.184 0.195 0.160 0.323 0.186 RMSE 0.209 0.116 0.223 0.219 0.210 0.363 0.223 MCD_DA MAE 0.125 0.068 0.229 0.217 0.165 0.385 0.198 RMSE 0.150 0.086 0.274 0.253 0.219 0.426 0.235 MCD_OC MAE 0.117 0.084 0.163 0.178 0.160 0.202 0.151 RMSE 0.144 0.106 0.220 0.216 0.208 0.234 0.188 -

[1] YAO Siya, KANG Qi, ZHOU Mengchu, et al. A survey of transfer learning for machinery diagnostics and prognostics[J]. Artificial Intelligence Review, 2023, 56(4): 2871–2922. doi: 10.1007/s10462-022-10230-4. [2] 王玉静, 康守强, 张云, 等. 基于集合经验模态分解敏感固有模态函数选择算法的滚动轴承状态识别方法[J]. 电子与信息学报, 2014, 36(3): 595–600. doi: 10.3724/SP.J.1146.2013.00434.WANG Yujing, KANG Shouqiang, ZHANG Yun, et al. Condition recognition method of rolling bearing based on ensemble empirical mode decomposition sensitive intrinsic mode function selection algorithm[J]. Journal of Electronics &Information Technology, 2014, 36(3): 595–600. doi: 10.3724/SP.J.1146.2013.00434. [3] 邵海东, 颜深, 肖一鸣, 等. 时变转速下基于改进图注意力网络的轴承半监督故障诊断[J]. 电子与信息学报, 2023, 45(5): 1550–1558. doi: 10.11999/JEIT220303.SHAO Haidong, YAN Shen, XIAO Yiming, et al. Semi-supervised bearing fault diagnosis using improved graph attention network under time-varying speeds[J]. Journal of Electronics &Information Technology, 2023, 45(5): 1550–1558. doi: 10.11999/JEIT220303. [4] 王玉静, 李少鹏, 康守强, 等. 结合CNN和LSTM的滚动轴承剩余使用寿命预测方法[J]. 振动、测试与诊断, 2021, 41(3): 439–446. doi: 10.16450/j.cnki.issn.1004-6801.2021.03.003.WANG Yujing, LI Shaopeng, KANG Shouqiang, et al. Method of predicting remaining useful life of rolling bearing combining CNN and LSTM[J]. Journal of Vibration,Measurement &Diagnosis, 2021, 41(3): 439–446. doi: 10.16450/j.cnki.issn.1004-6801.2021.03.003. [5] YANG Chuangyan, MA Jun, WANG Xiaodong, et al. A novel based-performance degradation indicator RUL prediction model and its application in rolling bearing[J]. ISA Transactions, 2022, 121: 349–364. doi: 10.1016/j.isatra.2021.03.045. [6] DING Ning, LI Hulin, YIN Zhongwei, et al. Journal bearing seizure degradation assessment and remaining useful life prediction based on long short-term memory neural network[J]. Measurement, 2020, 166: 108215. doi: 10.1016/j.measurement.2020.108215. [7] 王新刚, 韩凯忠, 王超, 等. 基于迁移学习的轴承剩余使用寿命预测方法[J]. 东北大学学报:自然科学版, 2021, 42(5): 665–672. doi: 10.12068/j.issn.1005-3026.2021.05.009.WANG Xingang, HAN Kaizhong, WANG Chao, et al. Bearing remaining useful life prediction method based on transfer learning[J]. Journal of Northeastern University:Natural Science, 2021, 42(5): 665–672. doi: 10.12068/j.issn.1005-3026.2021.05.009. [8] 雷亚国, 杨彬, 杜兆钧, 等. 大数据下机械装备故障的深度迁移诊断方法[J]. 机械工程学报, 2019, 55(7): 1–8. doi: 10.3901/JME.2019.07.001.LEI Yaguo, YANG Bin, DU Zhaojun, et al. Deep transfer diagnosis method for machinery in big data era[J]. Journal of Mechanical Engineering, 2019, 55(7): 1–8. doi: 10.3901/JME.2019.07.001. [9] CHENG Han, KONG Xianguang, CHEN Gaige, et al. Transferable convolutional neural network based remaining useful life prediction of bearing under multiple failure behaviors[J]. Measurement, 2021, 168: 108286. doi: 10.1016/j.measurement.2020.108286. [10] HU Tao, GUO Yiming, GU Liudong, et al. Remaining useful life prediction of bearings under different working conditions using a deep feature disentanglement based transfer learning method[J]. Reliability Engineering & System Safety, 2022, 219: 108265. doi: 10.1016/j.ress.2021.108265. [11] CHENG Han, KONG Xianguang, WANG Qibin, et al. The two-stage RUL prediction across operation conditions using deep transfer learning and insufficient degradation data[J]. Reliability Engineering & System Safety, 2022, 225: 108581. doi: 10.1016/j.ress.2022.108581. [12] ZOU Yisheng, LI Zhixuan, LIU Yongzhi, et al. A method for predicting the remaining useful life of rolling bearings under different working conditions based on multi-domain adversarial networks[J]. Measurement, 2022, 188: 110393. doi: 10.1016/j.measurement.2021.110393. [13] SAITO K, WATANABE K, USHIKU Y, et al. Maximum classifier discrepancy for unsupervised domain adaptation[C]. 2018 IEEE/CVF Conference on Computer Vision and Pattern Recognition, Salt Lake City, USA, 2018: 3723–3732. [14] BOUSMALIS K, TRIGEORGIS G, SILBERMAN N, et al. Domain separation networks[C]. The 30th International Conference on Neural Information Processing Systems, Barcelona, Spain, 2016: 343–351. [15] NECTOUX P, GOURIVEAU R, MEDJAHER K, et al. PRONOSTIA: An experimental platform for bearings accelerated degradation tests[C]. The IEEE International Conference on Prognostics and Health Management, Denver, USA, 2012: 1–8. [16] TZENG E, HOFFMAN J, ZHANG Ning, et al. Deep domain confusion: Maximizing for domain invariance[J]. arXiv preprint arXiv: 1412.3474, 2014. [17] GANIN Y, USTINOVA E, AJAKAN H, et al. Domain-adversarial training of neural networks[J]. The Journal of Machine Learning Research, 2016, 17(1): 2096–2030. [18] SUN Baochen and SAENKO K. Deep CORAL: Correlation alignment for deep domain adaptation[C]. The European Conference on Computer Vision, Amsterdam, The Netherlands, 2016: 443–450. -

下载:

下载:

下载:

下载: