Prediction and Compensation Method of Robot Positioning Error Based on Spatio-temporal Graph Convolution Neural Network

-

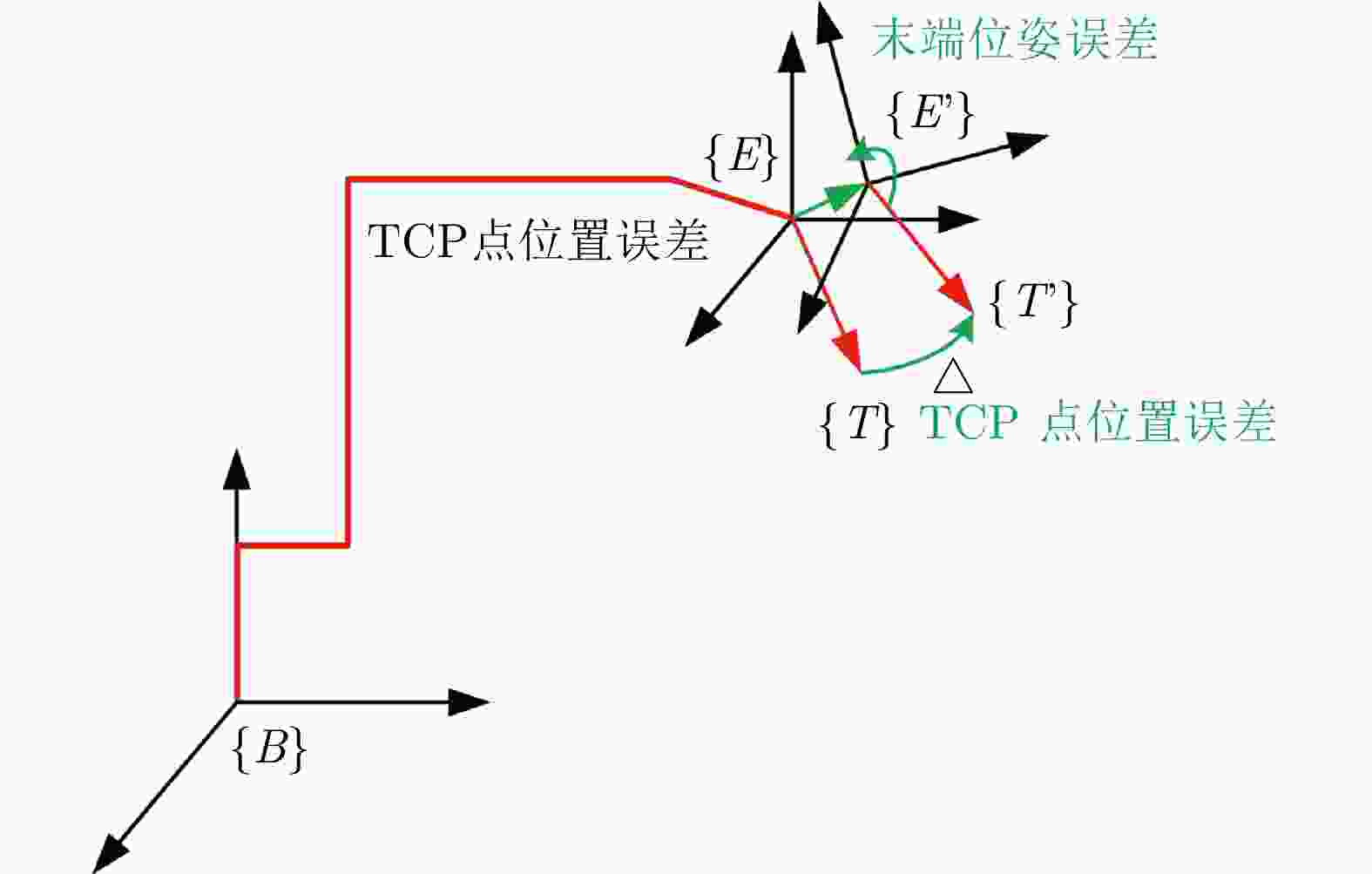

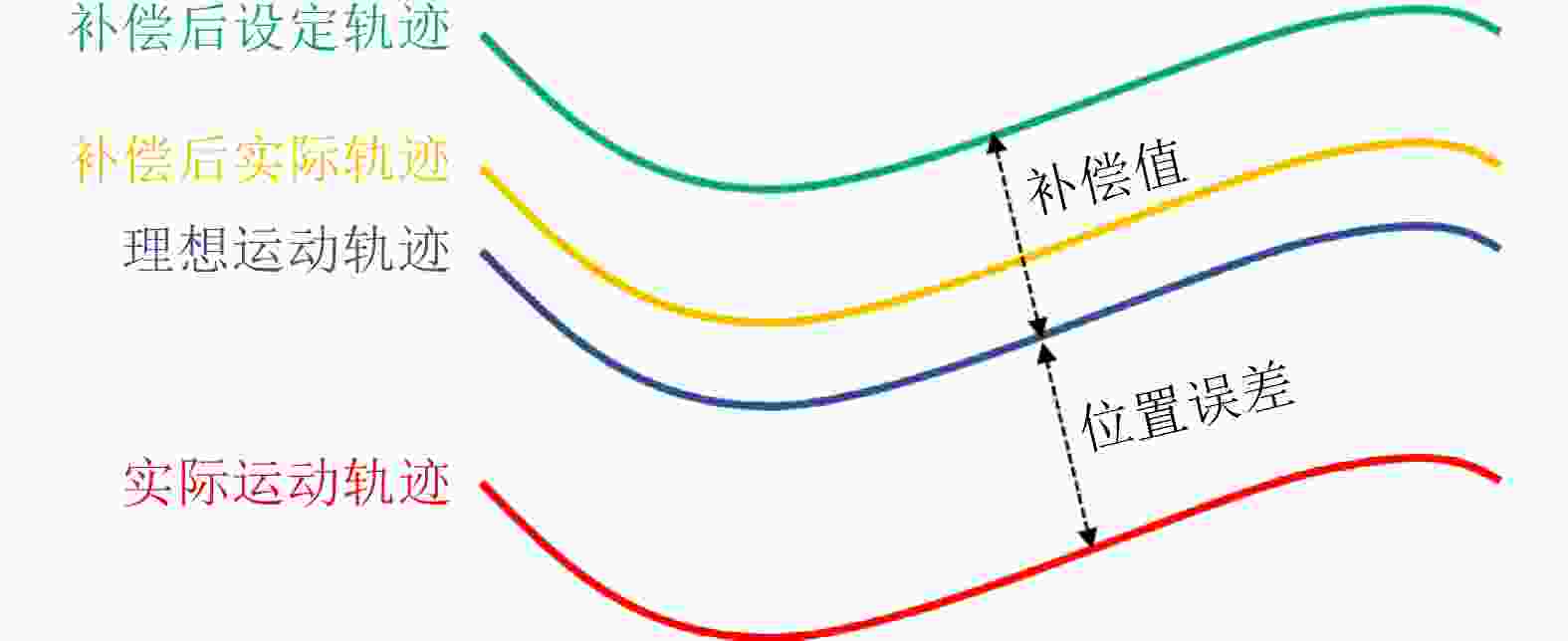

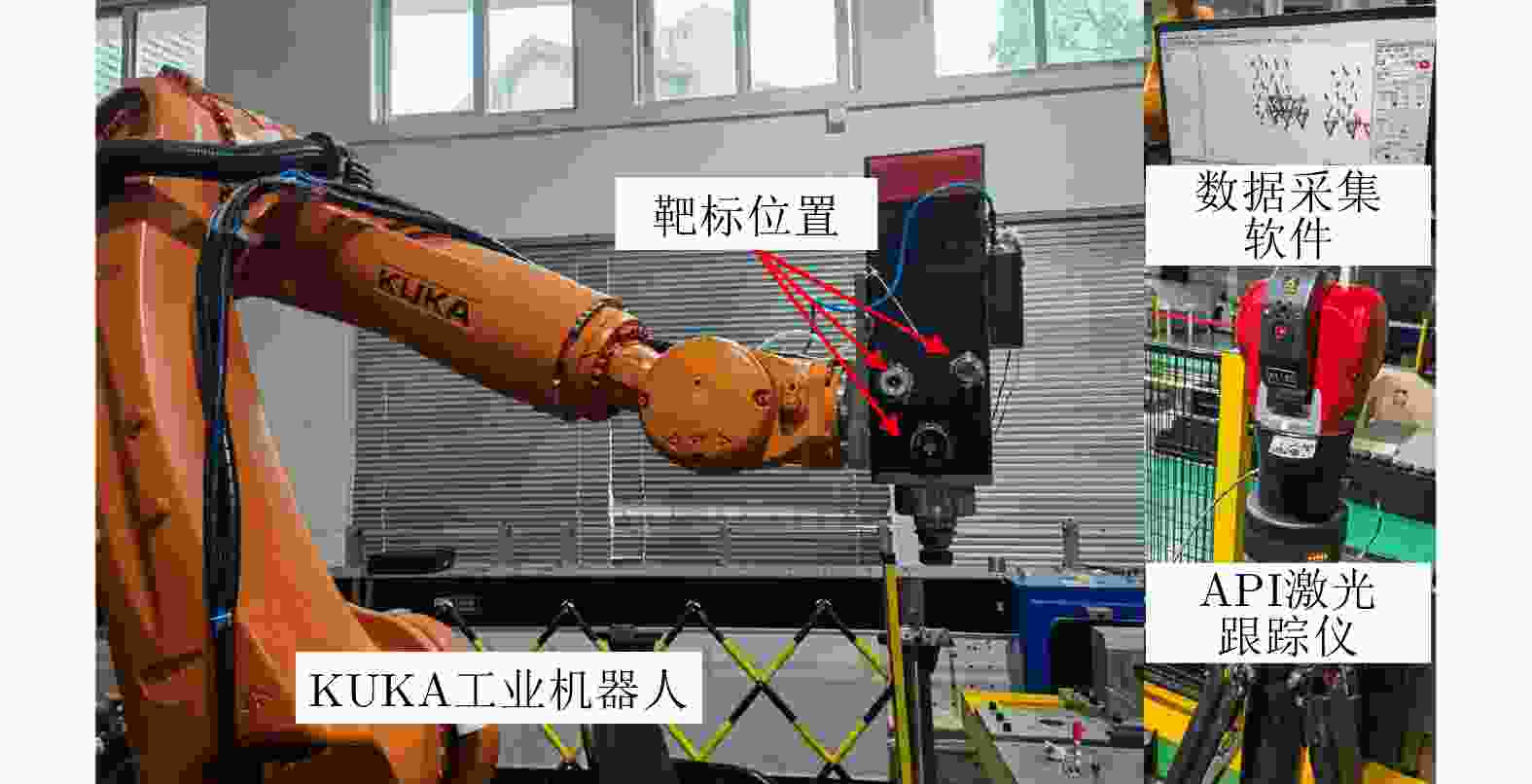

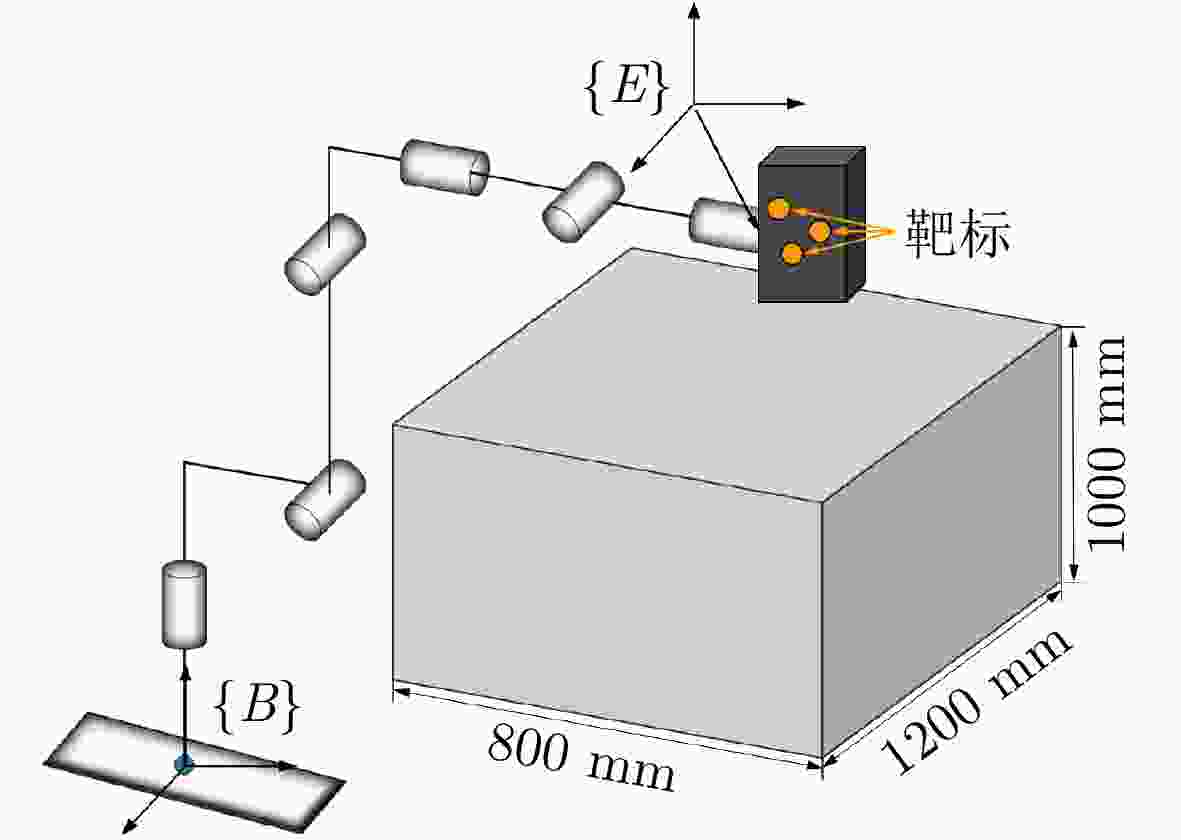

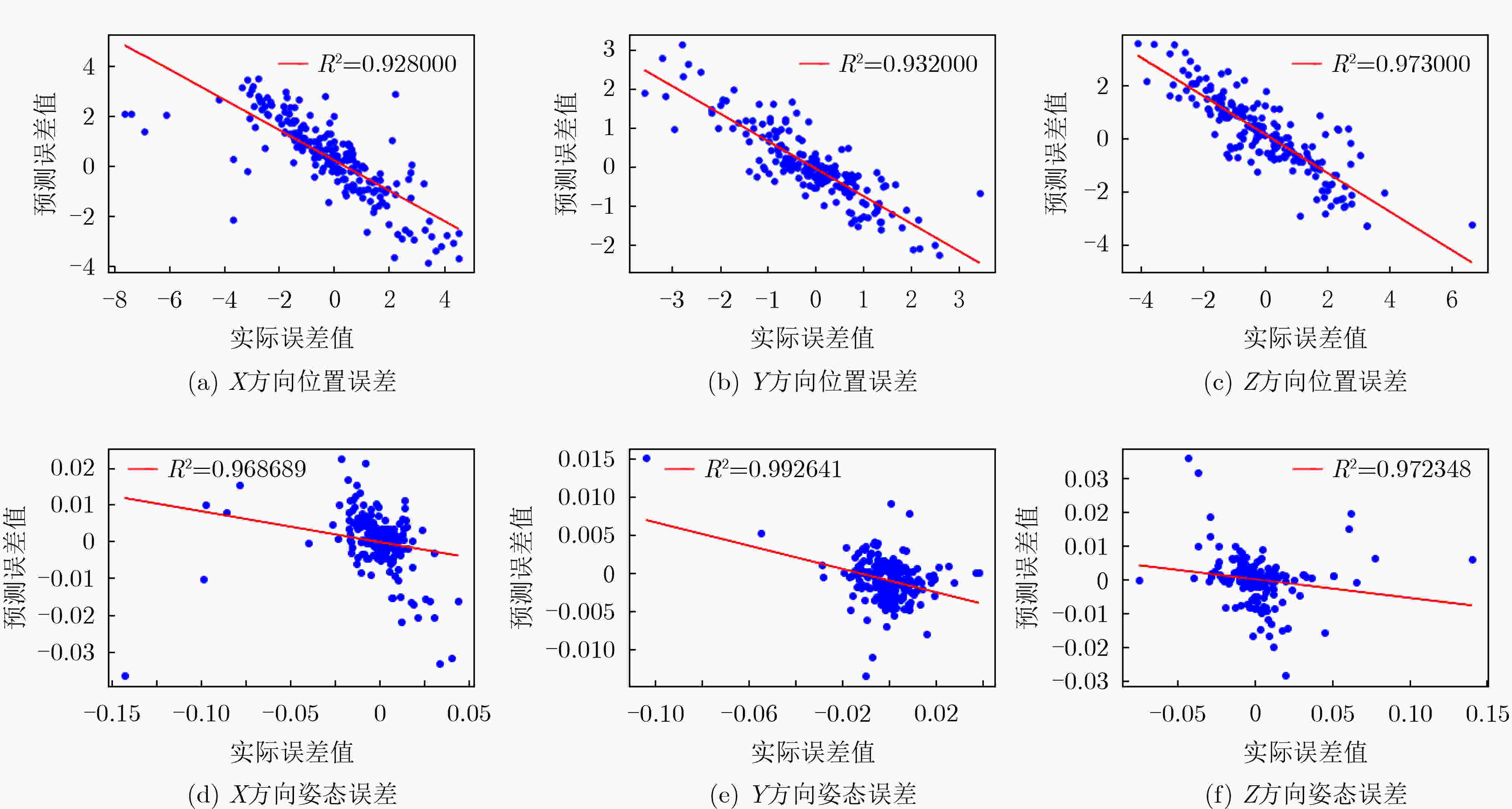

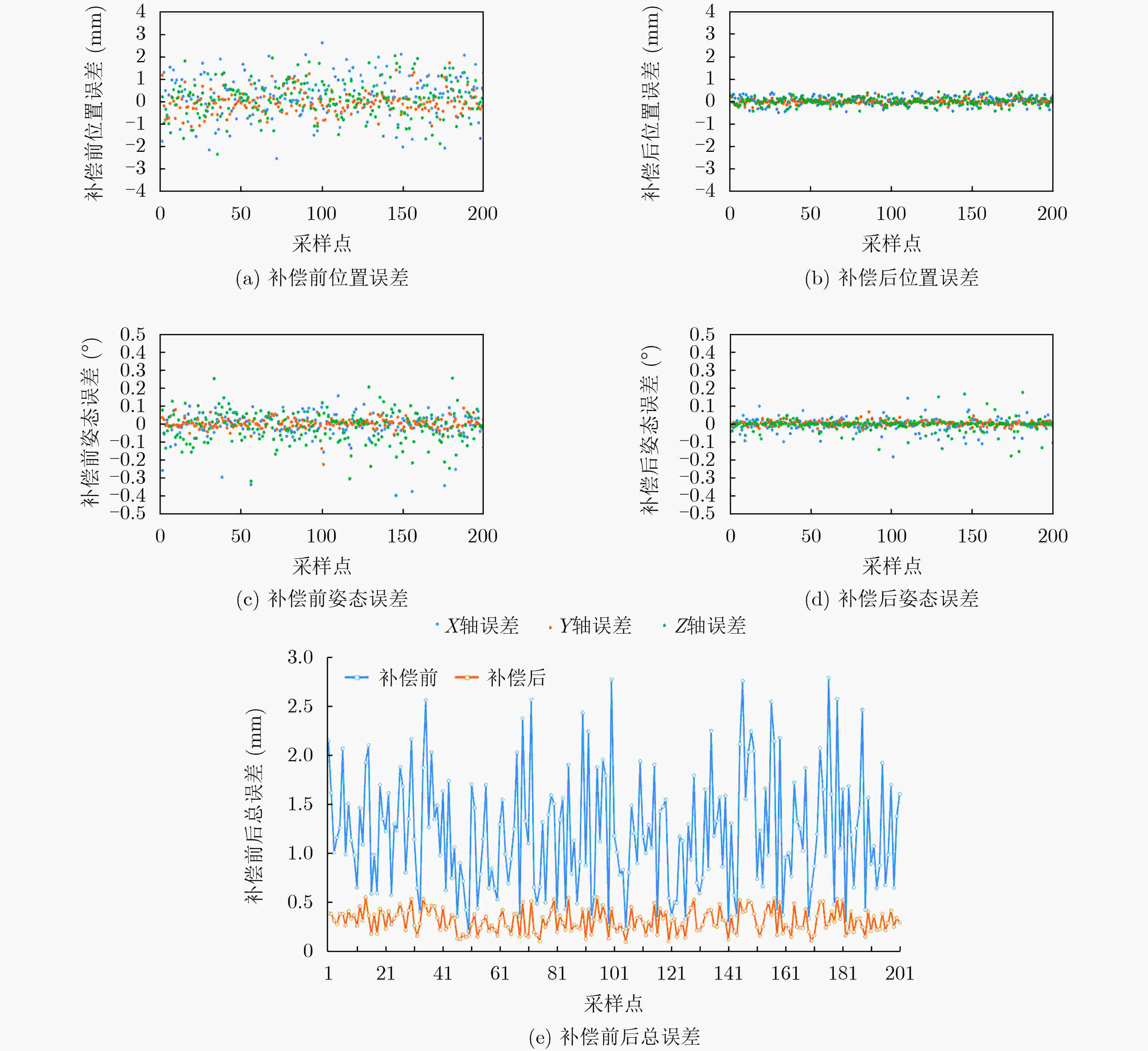

摘要: 工业机器人作为智能制造的重要载体,在大范围复杂任务中具有巨大潜力。但是,定位精度低且难以控制的问题阻碍了机器人在高精度任务的进一步推广。为了提升机器人作业精度,该文提出一种基于时空混合图卷积网络的机器人定位误差预测及补偿方法。首先通过设计图关系编码模块、时空混合特征解码模块,构建基于图卷积网络的机器人位姿误差预测模型;然后,针对传统迭代补偿方法中机器人逆解次数多导致效率低的问题,该文将定位误差补偿问题转化为优化问题,并利用遗传算法同时对位置和姿态进行误差补偿;最后,通过拉丁超立方抽样方法获得训练集,实现机器人定位误差预测模型的训练,并通过实验验证了定位误差预测的准确性以及补偿的效果。Abstract: As an important carrier of intelligent manufacturing, industrial robot has great potential in large-scale and complex tasks. However, the problem of low positioning accuracy and difficulty to control hinders the further popularization of robots in high-precision tasks. In order to improve the accuracy of robot operation, a robot positioning error prediction and compensation method based on spatio-temporal convolution graph network is proposed in this work. Firstly, through the design of graph relation coding module and spatio-temporal feature decoding module, the prediction model of the robot position and orientation error based on graph convolution network is constructed; Then, to solve the problem of low efficiency caused by too many times of robotic inverse kinematics solution in traditional iteration compensation methods, the problem of compensation for positioning errors is transformed into optimization problem, and the genetic algorithm is used to compensate the position and attitude errors simultaneously; Finally, the training set is obtained by Latin hypercube sampling method to realize the training of robot positioning error prediction model, and the accuracy of positioning error prediction and the effect of compensation are verified by the experiments.

-

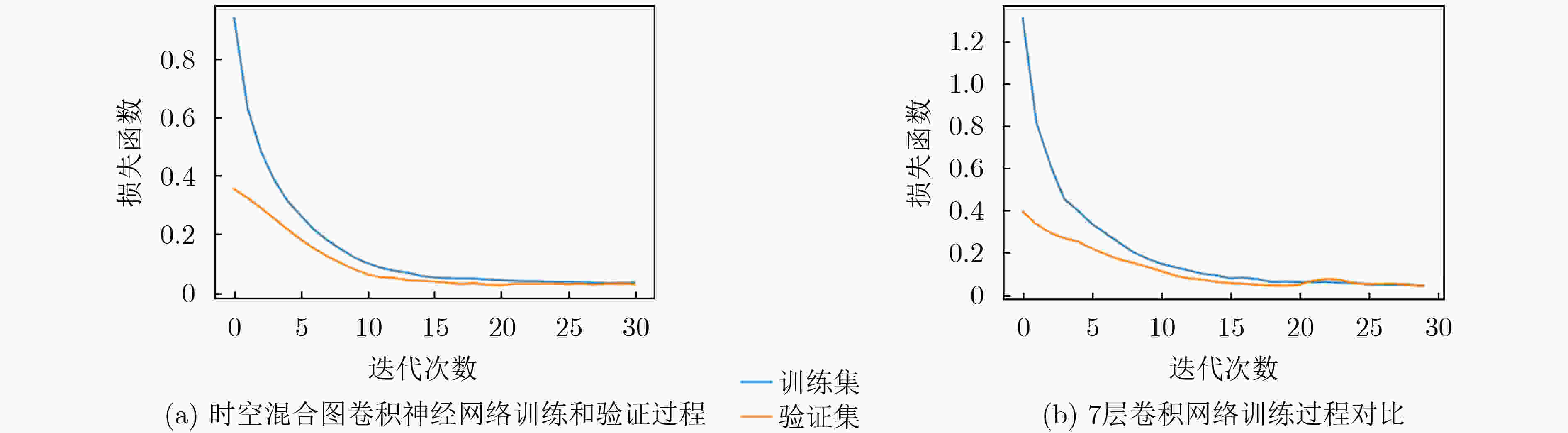

表 1 7层卷积网络的网络配置

层数 1 2 3 4 5 6 7 网络配置 Conv1D

(30, 3, relu)MaxPooling1D (2) Conv1D (1, 3, ReLU) MaxPooling1D (2) Dense

(50)Dense

(50)Dense

(6)表 2 7层卷积网络的网络配置

模型 误差 时空图卷积网络 0.0114 7层卷积网络 0.0526 -

[1] CHEN Yubao. Integrated and intelligent manufacturing: Perspectives and enablers[J]. Engineering, 2017, 3(5): 588–595. doi: 10.1016/J.ENG.2017.04.009 [2] ZHU Zerun, TANG Xiaowei, CHEN Chen, et al. High precision and efficiency robotic milling of complex parts: Challenges, approaches and trends[J]. Chinese Journal of Aeronautics, 2022, 35(2): 22–46. doi: 10.1016/j.cja.2020.12.030 [3] KIM S H, NAM E, HA T I, et al. Robotic machining: A review of recent progress[J]. International Journal of Precision Engineering and Manufacturing, 2019, 20(9): 1629–1642. doi: 10.1007/s12541-019-00187-w [4] GUO Yingjie, DONG Huiyue, WANG Guifeng, et al. Vibration analysis and suppression in robotic boring process[J]. International Journal of Machine Tools and Manufacture, 2016, 101: 102–110. doi: 10.1016/j.ijmachtools.2015.11.011 [5] YE Congcong, YANG Jixiang, ZHAO Huan, et al. Task-dependent workpiece placement optimization for minimizing contour errors induced by the low posture-dependent stiffness of robotic milling[J]. International Journal of Mechanical Sciences, 2021, 205: 106601. doi: 10.1016/j.ijmecsci.2021.106601 [6] NUBIOLA A and BONEV I A. Absolute calibration of an ABB IRB 1600 robot using a laser tracker[J]. Robotics and Computer-Integrated Manufacturing, 2013, 29(1): 236–245. doi: 10.1016/j.rcim.2012.06.004 [7] HU J, HUA F, and TIAN W. Robot positioning error compensation method based on deep neural network[J]. Journal of Physis Coference Series, 2020, 1487: 012045. [8] YANG Xiangdong, WU Liao, LI Jinquan, et al. A minimal kinematic model for serial robot calibration using POE formula[J]. Robotics and Computer-Integrated Manufacturing, 2014, 30(3): 326–334. doi: 10.1016/j.rcim.2013.11.002 [9] RENDERS J M, ROSSIGNOL E, BECQUET M, et al. Kinematic calibration and geometrical parameter identification for robots[J]. IEEE Transactions on Robotics and Automation, 1991, 7(6): 721–732. doi: 10.1109/70.105381 [10] MA Le, BAZZOLI P, SAMMONS P M, et al. Modeling and calibration of high-order joint-dependent kinematic errors for industrial robots[J]. Robotics and Computer-Integrated Manufacturing, 2018, 50: 153–167. doi: 10.1016/j.rcim.2017.09.006 [11] ALICI G and SHIRINZADEH B. A systematic technique to estimate positioning errors for robot accuracy improvement using laser interferometry based sensing[J]. Mechanism and Machine Theory, 2005, 40(8): 879–906. doi: 10.1016/j.mechmachtheory.2004.12.012 [12] NGUYEN H N, ZHOU Jian, and KANG H J. A calibration method for enhancing robot accuracy through integration of an extended Kalman filter algorithm and an artificial neural network[J]. Neurocomputing, 2015, 151: 996–1005. doi: 10.1016/j.neucom.2014.03.085 [13] NGUYEN H N, LE P N, and KANG H J. A new calibration method for enhancing robot position accuracy by combining a robot model–based identification approach and an artificial neural network–based error compensation technique[J]. Advances in Mechanical Engineering, 2019, 11(1): 1–11. doi: 10.1177/1687814018822935 [14] 王龙飞, 李旭, 张丽艳, 等. 工业机器人定位误差规律分析及基于ELM算法的精度补偿研究[J]. 机器人, 2018, 40(6): 843–851,859. doi: 10.13973/j.cnki.robot.170536WANG Longfei, LI Xu, ZHANG Liyan, et al. Analysis of the positioning error of industrial robots and accuracy compensation based on ELM algorithm[J]. Robot, 2018, 40(6): 843–851,859. doi: 10.13973/j.cnki.robot.170536 [15] LI Bo, TIAN Wei, ZHANG Chufan, et al. Positioning error compensation of an industrial robot using neural networks and experimental study[J]. Chinese Journal of Aeronautics, 2022, 35(2): 346–360. doi: 10.1016/j.cja.2021.03.027 [16] 周炜, 廖文和, 田威. 基于空间插值的工业机器人精度补偿方法理论与试验[J]. 机械工程学报, 2013, 49(3): 42–48. doi: 10.3901/JME.2013.03.042ZHOU Wei, LIAO Wenhe, and TIAN Wei. Theory and experiment of industrial robot accuracy compensation method based on spatial interpolation[J]. Journal of Mechanical Engineering, 2013, 49(3): 42–48. doi: 10.3901/JME.2013.03.042 [17] WANG Wei, TIAN Wei, LIAO Wenhe, et al. Error compensation of industrial robot based on deep belief network and error similarity[J]. Robotics and Computer-Integrated Manufacturing, 2022, 73: 102220. doi: 10.1016/j.rcim.2021.102220 [18] HU Ruihan, HUANG Qijun, WANG Hao, et al. Monitor-based spiking recurrent network for the representation of complex dynamic patterns[J]. International Journal of Neural Systems, 2019, 29(8): 1950006. doi: 10.1142/S0129065719500060 [19] SUN Peize, CAO Jinkun, JIANG Yi, et al. TransTrack: Multiple object tracking with transformer[J]. arXiv preprint arXiv: 2012.15460, 2020. [20] SHANG Chao, LIU Qinqing, TONG Qianqian, et al. Multi-view spectral graph convolution with consistent edge attention for molecular modeling[J]. Neurocomputing, 2021, 445: 12–25. doi: 10.1016/J.NEUCOM.2021.02.025 [21] LIAO Zhaoyang, WANG Qinghui, XIE Hailong, et al. Optimization of robot posture and workpiece setup in robotic milling with stiffness threshold[J]. IEEE/ASME Transactions on Mechatronics, 2022, 27(1): 582–593. doi: 10.1109/TMECH.2021.3068599 [22] VAN DAM E R, HUSSLAGE B, DEN HERTOG D, et al. Maximin Latin hypercube designs in two dimensions[J]. Operations Research, 2007, 55(1): 158–169. doi: 10.1287/opre.1060.0317 [23] HELSGAUN K. General k-opt submoves for the Lin–Kernighan TSP heuristic[J]. Mathematical Programming Computation, 2009, 1(2): 119–163. doi: 10.1007/s12532-009-0004-6 [24] HAYES T. R-squared change in structural equation models with latent variables and missing data[J]. Behavior Research Methods, 2021, 53(5): 2127–2157. doi: 10.3758/S13428-020-01532-Y [25] MISHRA V N, KUMAR V, PRASAD R, et al. Geographically weighted method integrated with logistic regression for analyzing spatially varying accuracy measures of remote sensing image classification[J]. Journal of the Indian Society of Remote Sensing, 2021, 49(5): 1189–1199. doi: 10.1007/s12524-020-01286-2 -

下载:

下载:

下载:

下载: