Adaptive Inspection for Void Defects Inside Solder Joints of Chip Resistors

-

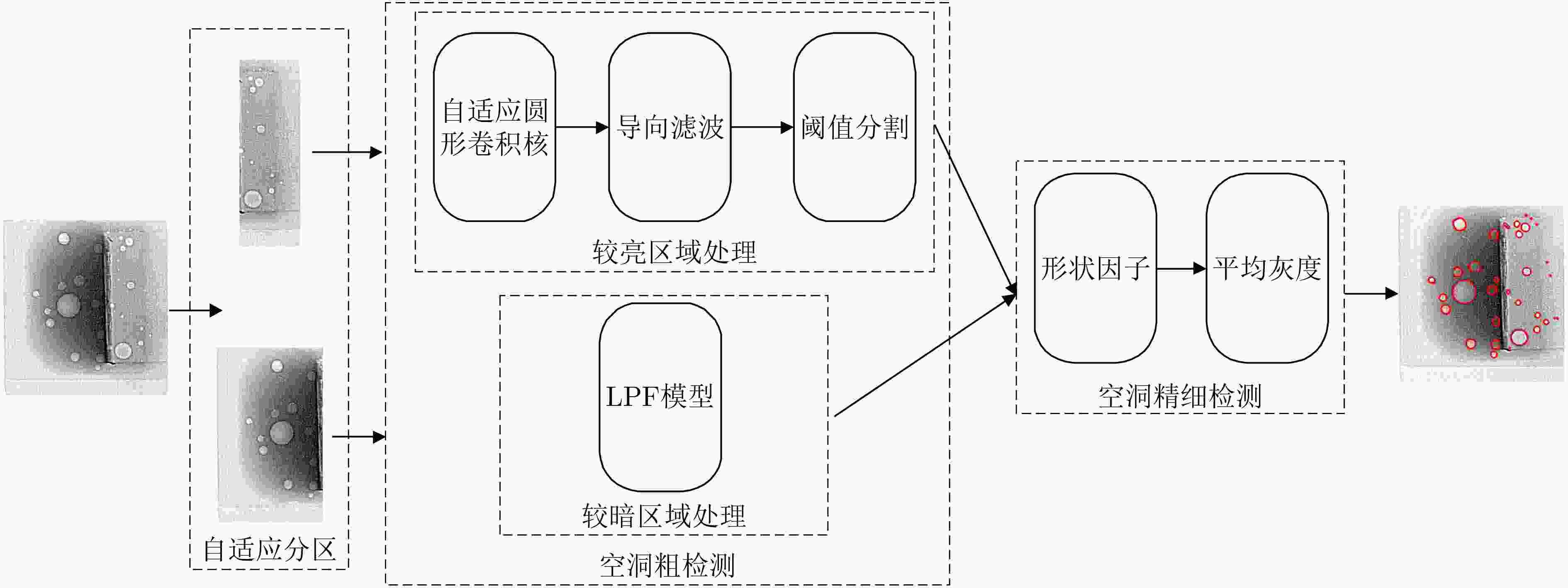

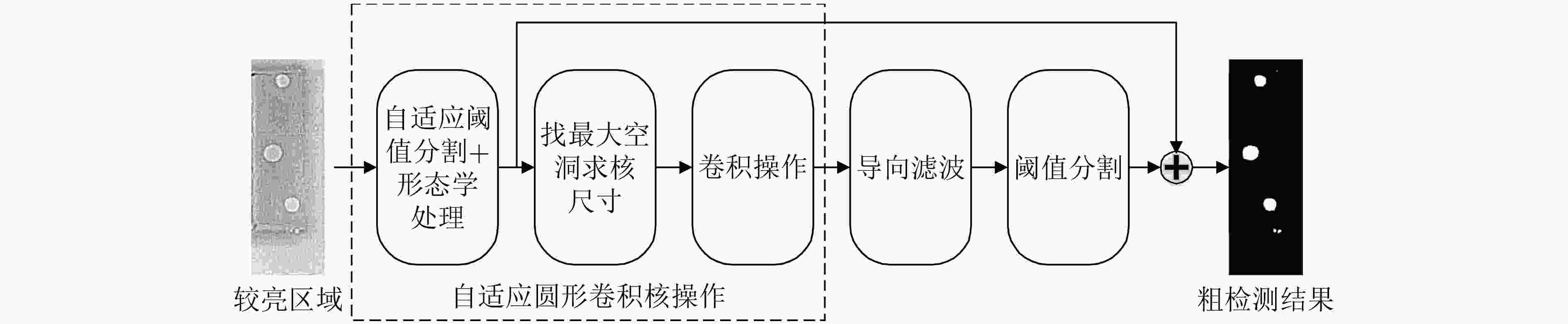

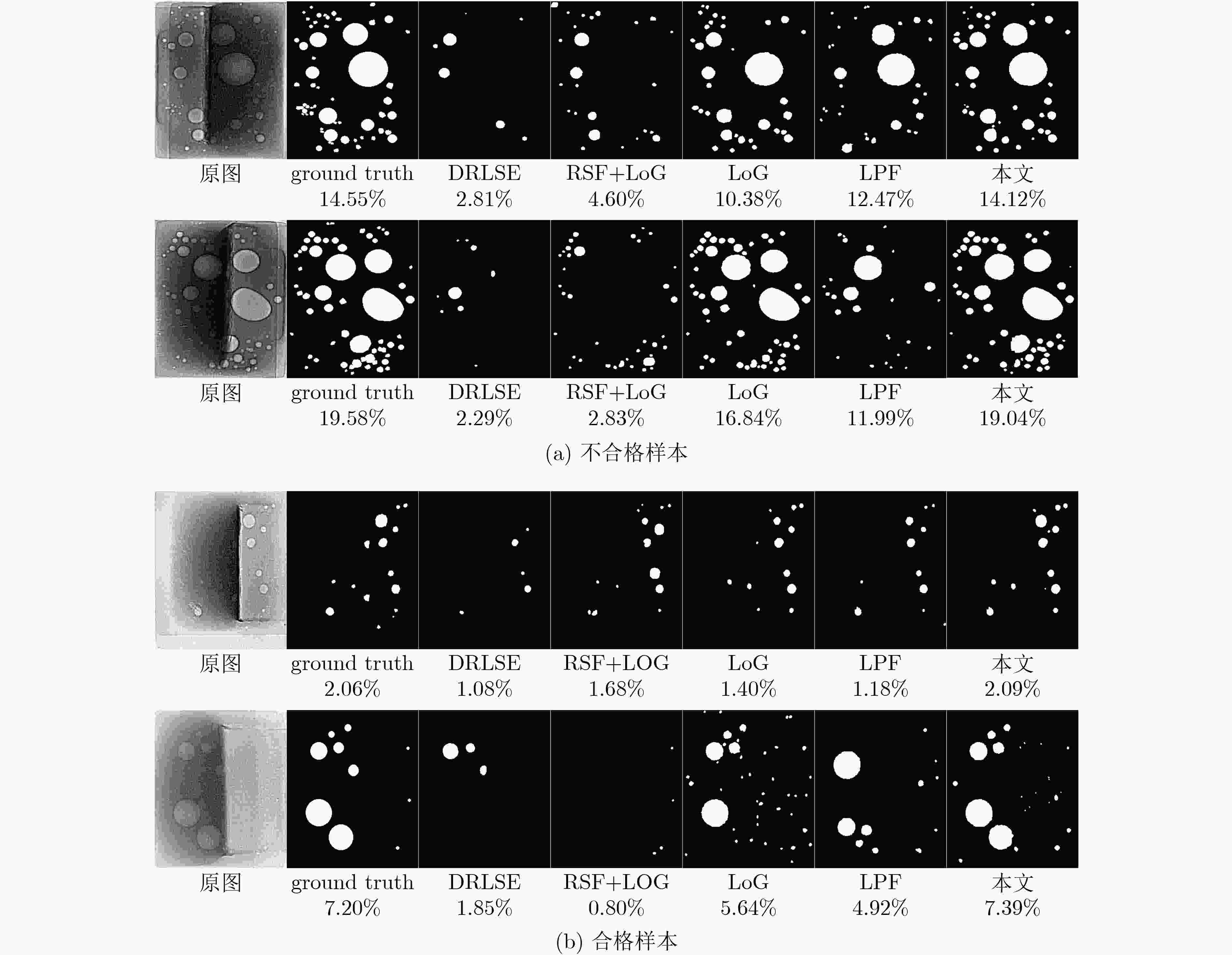

摘要: 贴片电阻在回流焊过程中,受工艺影响,焊点内部或多或少会存在空洞缺陷,空洞占比率过高会严重降低器件的可靠性。该文融合局部预拟合(LPF)活动轮廓模型和自适应圆形卷积核,提出一种贴片电阻焊点内部空洞缺陷自适应检测方法。首先,根据贴片电阻图像具有明暗两个明显区域的特点,通过求解区域平均灰度差异最大的优化问题将其自适应地分为较暗和较亮两个区域。然后,针对较暗区域中空洞与背景之间对比度低、空洞分布较稀疏、面积偏大等特点,采用局部预拟合活动轮廓模型进行空洞检测;针对较亮区域中空洞与背景之间差异明显、空洞分布密集、面积偏小等特点,提出一种自适应圆形卷积核检测空洞。最后,采用形状因子和平均灰度策略剔除误检测,实现贴片电阻焊点内部空洞精细检测。实验结果表明,该文算法相较于其他检测算法性能有明显的提升,平均Dice系数高达0.8846。

-

关键词:

- 空洞检测 /

- 贴片电阻 /

- 局部预拟合活动轮廓模型 /

- 自适应圆形卷积核 /

- 平均灰度策略

Abstract: In the process of reflow soldering, void defects inevitably emerge inside solder joints of chip resistors, which will influence reliability of the device. In this paper, an adaptive inspection method for void defects inside solder joints of chip resistors is proposed by combining a Local Pre-Fitted (LPF) active contour model and circular convolutions with adaptive kernels. First, since the image of chip resistor has two distinct regions, dark and bright regions are adaptively separated from the image after solving the optimization problem with the largest difference between the average gray level values of the two regions. Then, considering low contrast between voids and the image background, sparse distribution and large areas of voids in the dark region, LPF active contour model is used to inspect voids. As for the obvious difference between voids and the image background, dense distribution and small areas of voids in the bright region, circular convolutions with adaptive kernels are proposed to inspect voids. Finally, false detection can be eliminated by the shape factor and an average gray strategy to realize accurate void inspection. Experimental results show that the proposed method is superior to other inspection methods with an average Dice coefficient of 0.8846. -

表 1 不同尺寸圆形卷积核的检测性能对比

9×9 29×29 49×49 99×99 199×199 本文 Dice系数 0.4413 0.7287 0.7321 0.7736 0.7479 0.8453 处理时间(s) 0.204 0.218 0.224 0.229 0.253 0.327 表 2 LPF不同对核的分割Dice系数和消耗时间

3×3 5×5 7×7 9×9 11×11 13×13 Dice系数 0.8562 0.8872 0.8880 0.8910 0.8907 0.8881 处理时间(s) 2.648 4.360 7.075 10.626 15.020 20.305 表 3 亮、暗区域的消融实验(Dice)

较亮区域 较暗区域 自适应圆形卷积核 0.8453 0.3976 LPF 0.7951 0.8637 表 4 不同算法的空洞缺陷检测统计结果

指标 Acc(%) F1 Dice DRLSE 79.10 0.8833 0.5630 RSF+LoG 79.10 0.8833 0.5965 LoG 92.54 0.9545 0.8576 U-Net 88.06 0.9298 0.7650 LPF 85.82 0.9177 0.8637 本文 95.52 0.9725 0.8846 -

[1] ILLÉS B, KRAMMER O, and GÉCZY A. Reflow Soldering: Apparatus and Heat Transfer Processes[M]. Amsterdam: Elsevier, 2020: 5–8. [2] SAID A F, BENNETT B L, KARAM L J, et al. Automated void detection in solder balls in the presence of vias and other artifacts[J]. IEEE Transactions on Components, Packaging and Manufacturing Technology, 2012, 2(11): 1890–1901. doi: 10.1109/TCPMT.2011.2182613 [3] WILD P, LORENZ D, GRÖZINGER T, et al. Effect of voids on thermo-mechanical reliability of chip resistor solder joints: Experiment, modelling and simulation[J]. Microelectronics Reliability, 2018, 85: 163–175. doi: 10.1016/j.microrel.2018.04.014 [4] BUŠEK D, DUŠEK K, RŮŽIČKA D, et al. Flux effect on void quantity and size in soldered joints[J]. Microelectronics Reliability, 2016, 60: 135–140. doi: 10.1016/j.microrel.2016.03.009 [5] WANG Yu, WANG Mingquan, and ZHANG Zhijie. Microfocus X-ray printed circuit board inspection system[J]. Optik, 2014, 125(17): 4929–4931. doi: 10.1016/j.ijleo.2014.04.027 [6] PENG Shaohu and DO NAM H. Void defect detection in ball grid array X-ray images using a new blob filter[J]. Journal of Zhejiang University SCIENCE C, 2012, 13(11): 840–849. doi: 10.1631/jzus.C1200065 [7] MOURI M, KATO Y, YASUKAWA H, et al. A study of using nonnegative matrix factorization to detect solder-voids from radiographic images of solder[C]. The 2014 IEEE 23rd International Symposium on Industrial Electronics, Istanbul, Turkey, 2014: 1074–1079. [8] NUANPRASERT S, BABA S, and SUZUKI T. A simple automated void defect detection for poor contrast x-ray images of BGA[C]. The 3rd International Conference on Industrial Application Engineering, Kitakyushu, Japan, 2015. [9] MOORE T D, VANDERSTRAETEN D, and FORSSELL P M. Three-dimensional X-ray laminography as a tool for detection and characterization of BGA package defects[J]. IEEE Transactions on Components and Packaging Technologies, 2002, 25(2): 224–229. doi: 10.1109/TCAPT.2002.1010010 [10] NEELURU V K and AHUJA V. Void region segmentation in ball grid array using u-net approach and synthetic data[J]. arXiv: 1907.04222, 2019. [11] AKDENİZ C T, DOKUR Z, and ÖLMEZ T. Detection of BGA solder defects from X-ray images using deep neural network[J]. Turkish Journal of Electrical Engineering & Computer Sciences, 2020, 28(4): 2020–2029. doi: 10.3906/elk-1910-135 [12] DING Keyan, XIAO Linfang, and WENG Guirong. Active contours driven by local pre-fitting energy for fast image segmentation[J]. Pattern Recognition Letters, 2018, 104: 29–36. doi: 10.1016/j.patrec.2018.01.019 [13] HE Kaiming and SUN Jian. Fast guided filter[J]. arXiv: 1505.00996, 2015. [14] LI Chunming, XU Chenyang, GUI Changfeng, et al. Distance regularized level set evolution and its application to image segmentation[J]. IEEE Transactions on Image Processing, 2010, 19(12): 3243–3254. doi: 10.1109/TIP.2010.2069690 [15] DING Keyan, XIAO Linfang, and WENG Guirong. Active contours driven by region-scalable fitting and optimized Laplacian of Gaussian energy for image segmentation[J]. Signal Processing, 2017, 134: 224–233. doi: 10.1016/j.sigpro.2016.12.021 [16] GAO Shangbing, YANG Jian, and YAN Yunyang. A novel multiphase active contour model for inhomogeneous image segmentation[J]. Multimedia Tools and Applications, 2014, 72(3): 2321–2337. doi: 10.1007/s11042-013-1553-2 [17] WANG Lei, CHANG Yan, WANG Hui, et al. An active contour model based on local fitted images for image segmentation[J]. Information Sciences, 2017, 418/419: 61–73. doi: 10.1016/j.ins.2017.06.042 [18] ZHAO Wencheng, XU Xianze, ZHU Yanyan, et al. Active contour model based on local and global Gaussian fitting energy for medical image segmentation[J]. Optik, 2018, 158: 1160–1169. doi: 10.1016/j.ijleo.2018.01.004 [19] 罗钧, 杨永松, 侍宝玉. 基于改进的自适应差分演化算法的二维Otsu多阈值图像分割[J]. 电子与信息学报, 2019, 41(8): 2017–2024. doi: 10.11999/JEIT180949LUO Jun, YANG Yongsong, and SHI Baoyu. Multi-threshold image segmentation of 2D Otsu based on improved adaptive differential evolution algorithm[J]. Journal of Electronics &Information Technology, 2019, 41(8): 2017–2024. doi: 10.11999/JEIT180949 [20] SHANG Caijie, ZHANG Dong, and YANG Yan. A gradient-based method for multilevel thresholding[J]. Expert Systems with Applications, 2021, 175: 114845. doi: 10.1016/j.eswa.2021.114845 -

下载:

下载:

下载:

下载: