Inspection of Slight Aesthetic Defects in a Polarizing Film via Polarization Imaging

-

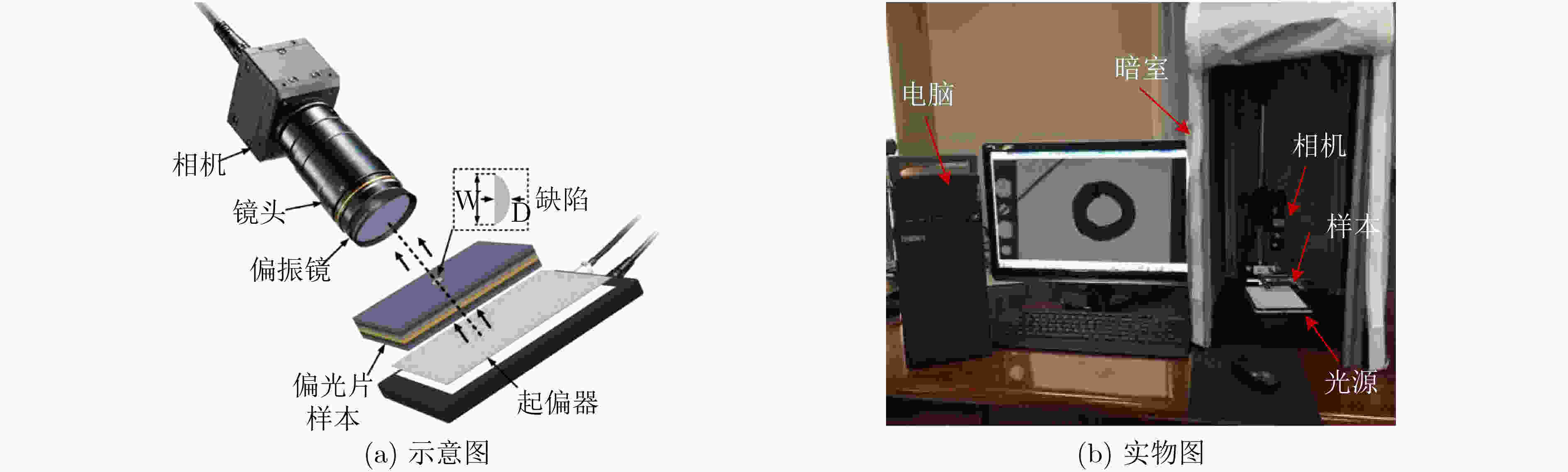

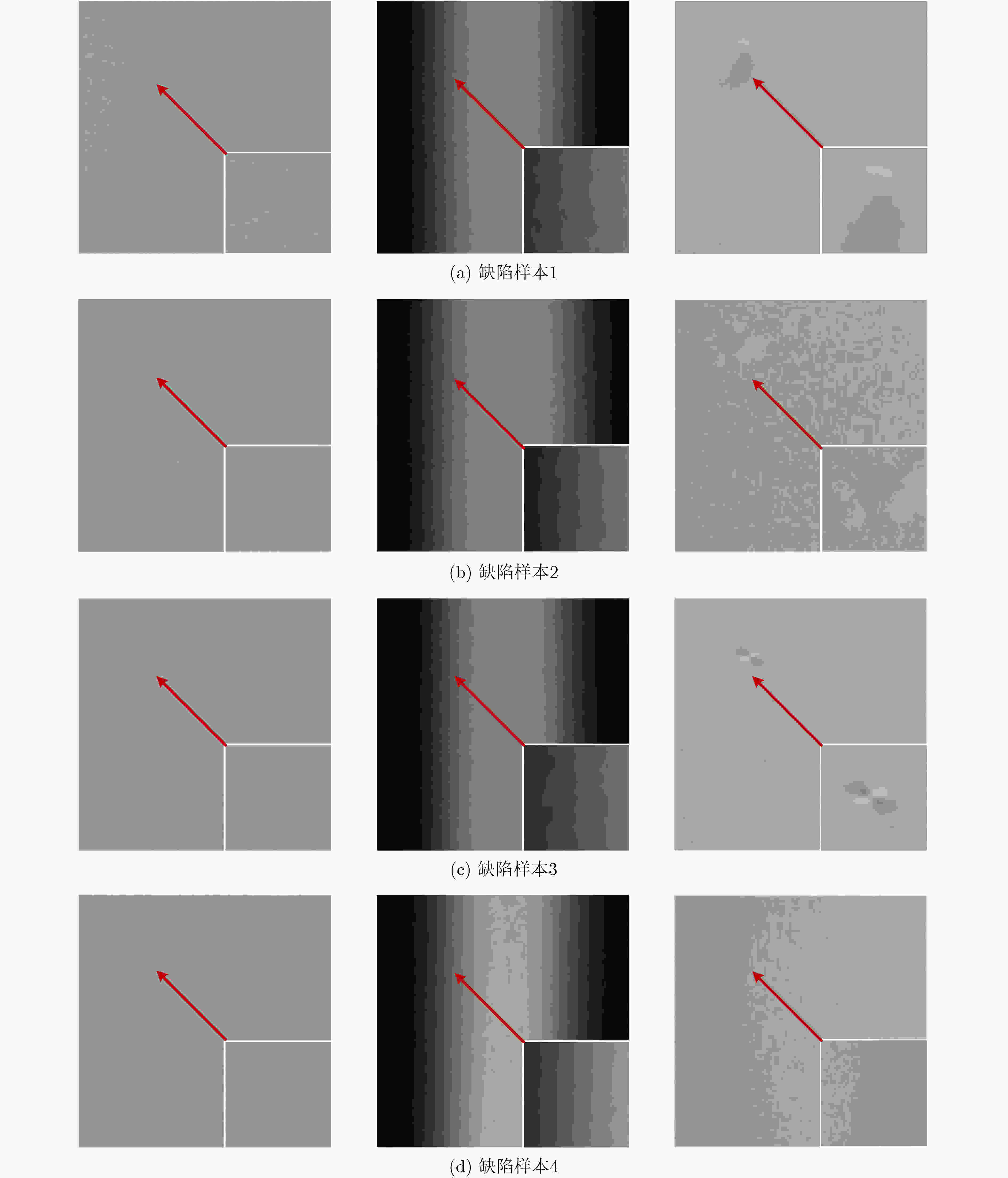

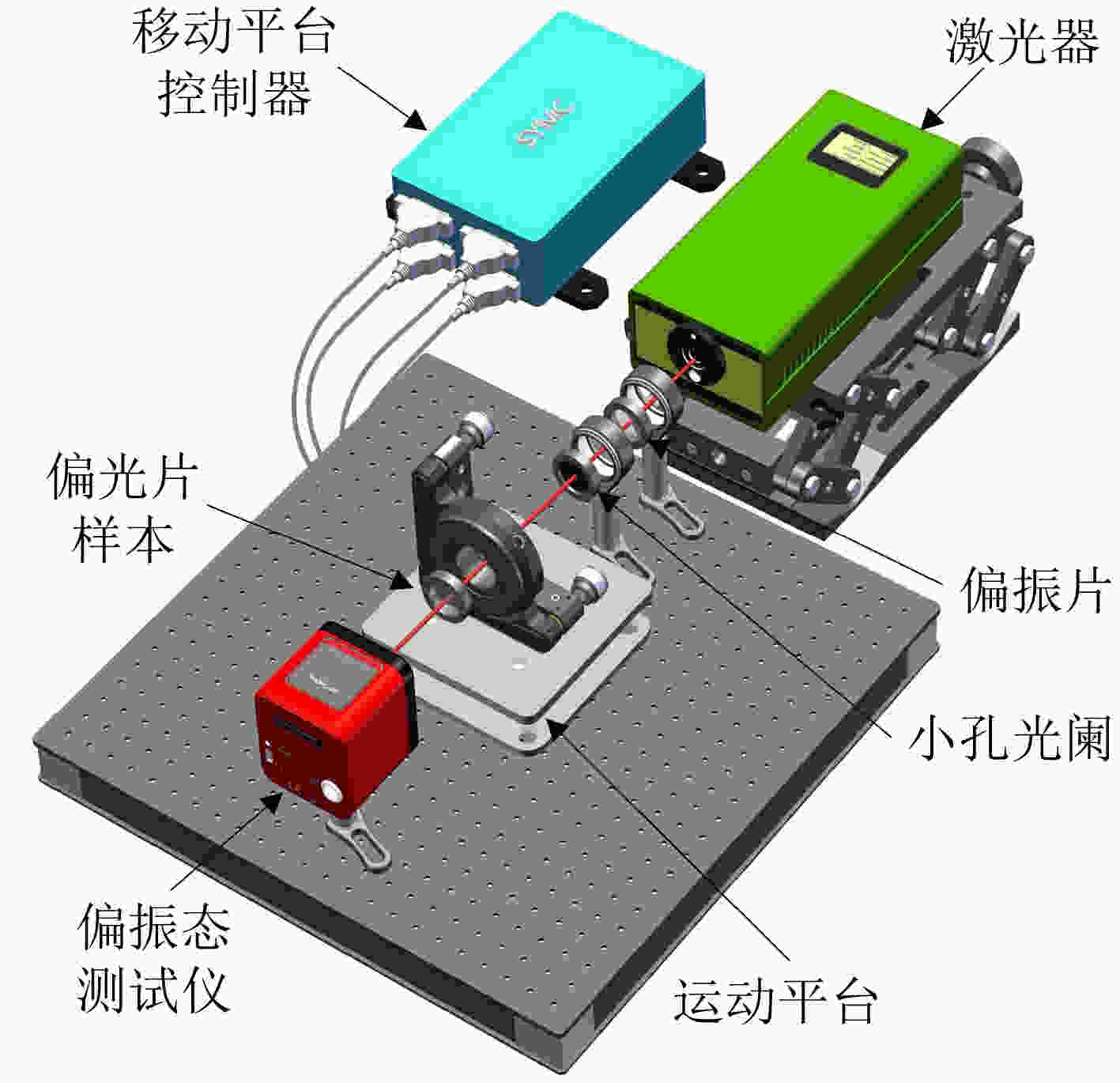

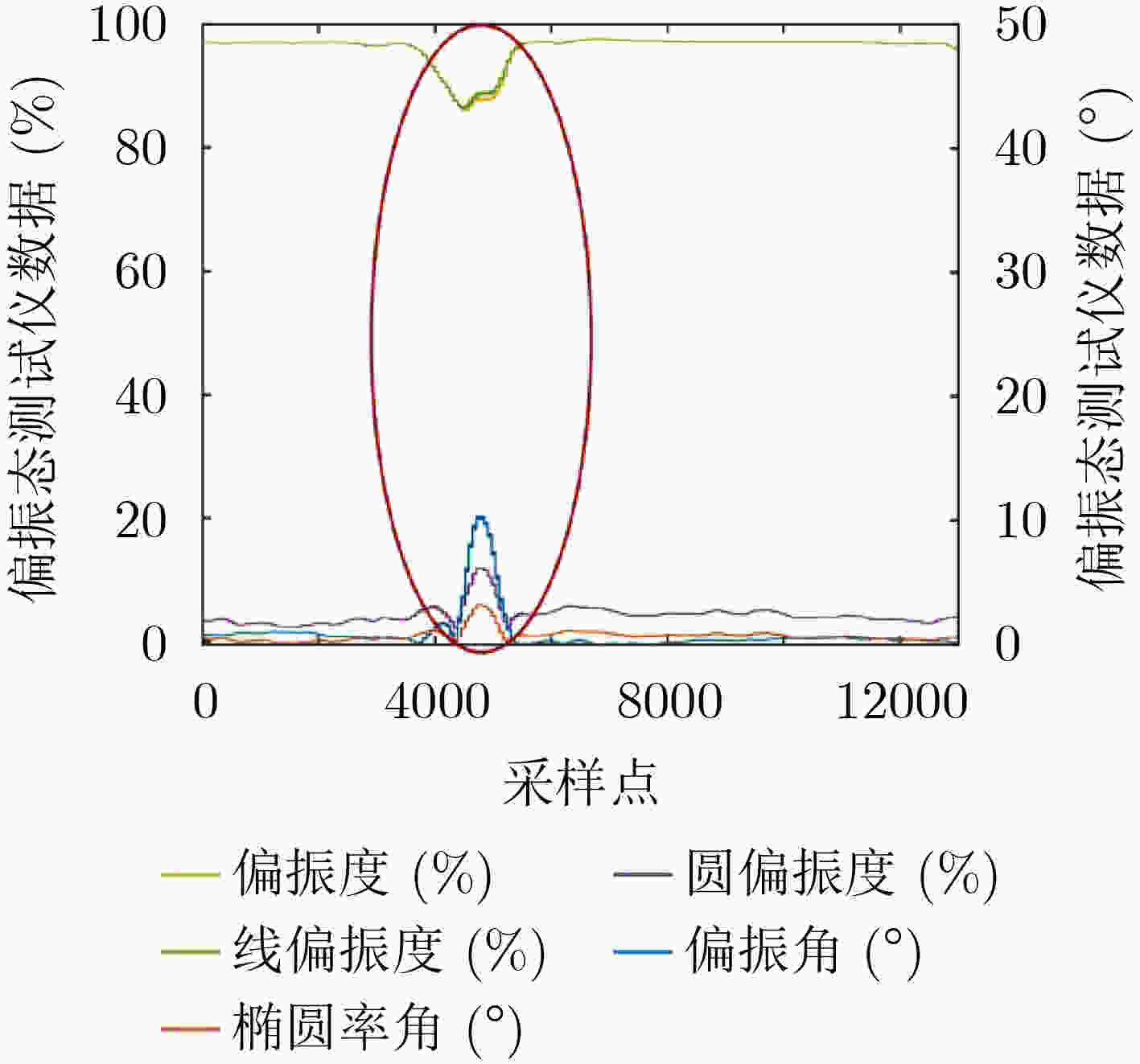

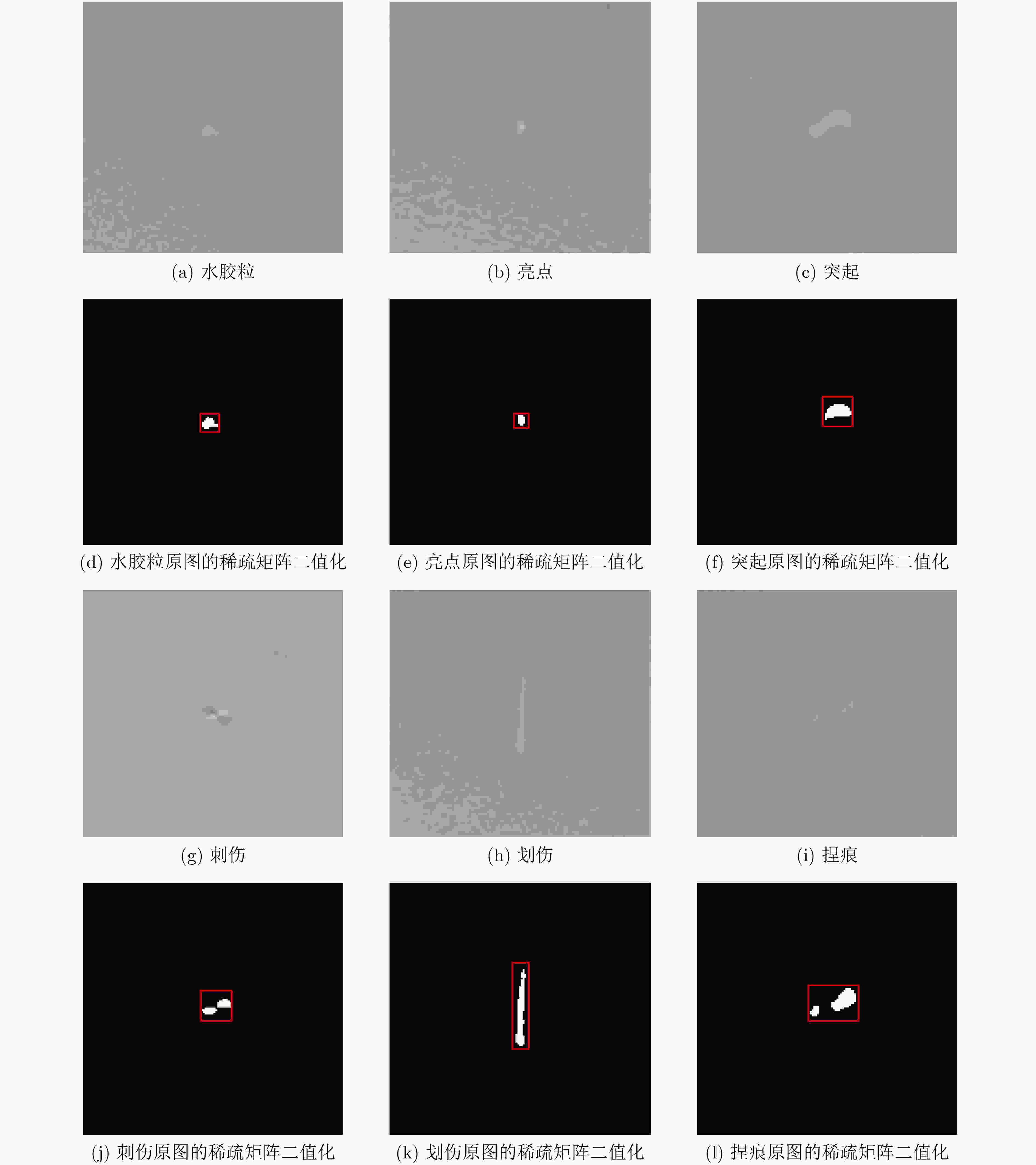

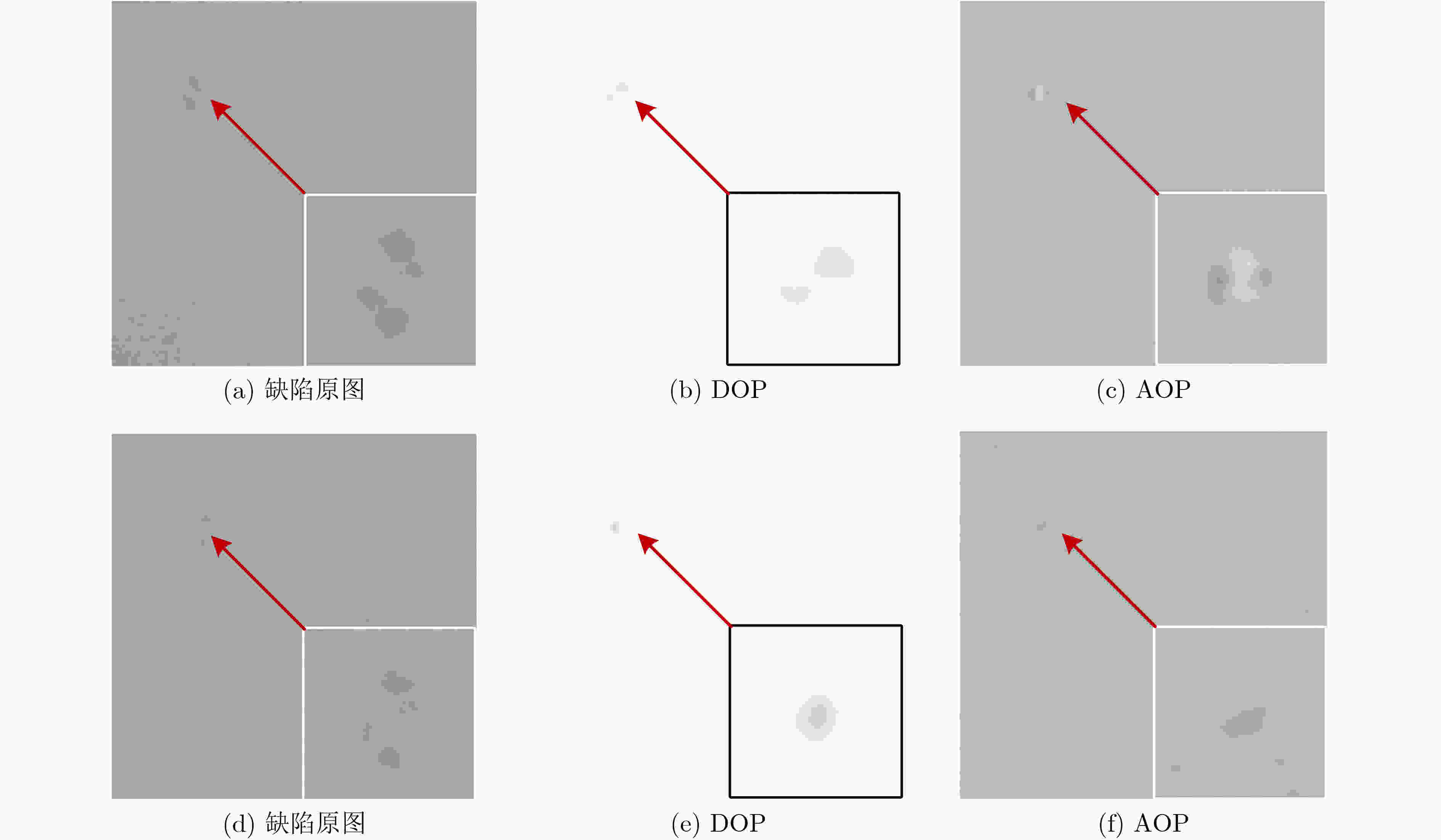

摘要: 针对偏光片细微外观缺陷难以成像、难以检测的问题,该文提出一种基于偏振成像的外观缺陷检测新方法。通过缺陷偏振态指标测量结果,定性描述了对比度增强机理。利用缺陷与正常区域之间透射光偏振态的显著差异,大幅提高缺陷的成像对比度,从而简化后续图像处理算法,提高检测速度和准确率。实验结果表明,偏光片外观缺陷平均检出率达到97.3%,平均单个样品检测时间约为0.22 s,基本满足产业化应用要求。Abstract: The slight aesthetic defects of polarizing films can hardly image and are difficult to detect. A novel method of detecting the slight defects based on polarization imaging is proposed in this paper. The mechanism of contrast enhancement is described qualitatively through the measurement results of defect polarization index. The image contrast of the defect is greatly improved by making use of the significant difference of polarization state of the transmitted light between the defect and the normal region, so as to simplify the following image processing algorithm and improve both the detection speed and accuracy. The experimental results show that the average recognition rate of polarizer aesthetic defects is 97.3%, and the average detection time of a single defect sample is about 0.22 s, thus it meets basically the requirements of industrial application.

-

表 1 凹痕缺陷对比度

偏光片样本与检偏器夹角(º) 0 10 20 30 40 50 60 70 80 90 对比度(%) 11.0 11.6 12.0 12.7 14.3 14.1 12.1 11.6 10.2 8.8 表 2 偏振态指标的最大差值(缺陷与正常区域之间)

缺陷类型 偏振度(%) 线偏振度(%) 圆偏振度(%) 偏振角(°) 椭圆率角(°) 水胶粒 4.84 4.54 8.50 0.46 2.81 亮点 2.20 2.23 1.45 1.58 1.59 蝶纹 1.79 2.06 6.65 2.61 2.74 划伤 1.82 2.84 1.50 1.26 0.23 突起 6.43 6.44 0.69 0.32 0.51 表 3 缺陷检出率对比

缺陷类型 数量 结构光成像 偏振成像 检出数量 检出率(%) 检出数量 检出率(%) 突起 3 0 0 3 100.0 捏痕 3 0 0 3 100.0 刺伤 4 0 0 4 100.0 指痕 5 0 0 4 80.0 蝶纹 7 5 71.4 7 100.0 亮点 36 33 91.7 34 94.4 水胶粒 38 36 94.7 37 97.4 划伤 54 52 96.3 54 100.0 总计 150 126 84.0 146 97.3 -

[1] YOON Y G, LEE S L, CHUNG C W, et al. An effective defect inspection system for polarized film images using image segmentation and template matching techniques[J]. Computers & Industrial Engineering, 2008, 55(3): 567–583. doi: 10.1016/j.cie.2008.01.015 [2] KUO C C F J, CHIU C H, and CHOU Y C. Research and development of intelligent on-line real-time defect inspection system for polymer polarizer[J]. Polymer-Plastics Technology and Engineering, 2009, 48(2): 185–192. doi: 10.1080/03602550802634501 [3] CHENG C C and JAO H M. Application of the Haar wavelet to Mura detection for polarizer[C]. 2013 IEEE International Conference on Industrial Technology (ICIT), Cape Town, South Africa, 2013: 1080–1085. [4] YEN H N and SYU M J. Inspection of polarizer tiny bump defects using computer vision[C]. 2015 IEEE International Conference on Consumer Electronics (ICCE), Las Vegas, USA, 2015: 525–527. [5] WON Y, JOO H, and KIM J. Classification of defects in the polarizer of display panels using the Convolution Neural Network (CNN)[J]. International Journal of Computing, Communications and Instrumentation Engineering (IJCCIE), 2017, 4(1): 139–142. doi: 10.15242/IJCCIE.E0217018. [6] KUO C F J, LAI Chunyu, KAO C H, et al. Integrating image processing and classification technology into automated polarizing film defect inspection[J]. Optics and Lasers in Engineering, 2018, 104: 204–219. doi: 10.1016/j.optlaseng.2017.09.017 [7] LEI Haiwei, WANG Bin, WU Hehe, et al. Defect detection for polymeric polarizer based on faster R-CNN[J]. Journal of Information Hiding and Multimedia Signal Processing, 2018, 9(6): 1414–1420. doi: 10.15242/ijccie.e0217018 [8] LIU Ruizhen, SUN Zhiyi, WANG Anhong, et al. Lightweight efficient network for defect classification of polarizers[J]. Concurrency and Computation:Practice and Experience, 2020, 32(11): e5663. doi: 10.1002/cpe.5663 [9] LAI Wenwei, ZENG Xiaoxing, HE Jian, et al. Aesthetic defect characterization of a polymeric polarizer via structured light illumination[J]. Polymer Testing, 2016, 53: 51–57. doi: 10.1016/j.polymertesting.2016.05.011 [10] DENG Yuanlong, XU Shaopeng, CHEN Haoquan, et al. Inspection of extremely slight aesthetic defects in a polymeric polarizer using the edge of light between black and white stripes[J]. Polymer Testing, 2018, 65: 169–175. doi: 10.1016/j.polymertesting.2017.11.019 [11] 熊志航, 廖然, 曾亚光, 等. 利用偏振成像在复杂现场快速识别金属碎屑[J]. 红外与激光工程, 2020, 49(6): 10–15. doi: 10.3788/IRLA20201012XIONG Zhihang, LIAO Ran, ZENG Yaguang, et al. Rapid identification of metal debris in complicated scenes by using polarization imaging[J]. Infrared and Laser Engineering, 2020, 49(6): 10–15. doi: 10.3788/IRLA20201012 [12] 李嘉晋, 廖然, 卓泽鹏, 等. 利用偏振光散射技术的藻类絮凝过程监测[J]. 大气与环境光学学报, 2020, 15(1): 72–80. doi: 10.3969/J.issn.1673-6141.2020.01.008LI Jiajin, LIAO Ran, ZHUO Zepeng, et al. Monitoring of algal flocculation using polarized light scattering[J]. Journal of Atmospheric and Environmental Optics, 2020, 15(1): 72–80. doi: 10.3969/J.issn.1673-6141.2020.01.008 [13] FECHNER G T, HOWES D H, and BORING E G. Elements of Psychophysics[M]. New York: Holt, Rinehart and Winston, 1966. doi: 10.1037/11304–026. [14] 罗勇江, 杨腾飞, 赵冬. 色噪声下基于白化频谱重排鲁棒主成分分析的语音增强算法[J]. 电子与信息学报, 2021, 43(12): 3671–3679. doi: 10.11999/JEI200594LUO Yongjiang, YANG Tengfei, and ZHAO Dong. Speech enhancement algorithm based on robust principal component analysis with whitened spectrogram rearrangement in colored noise[J]. Journal of Electronics and Information Technology, 2021, 43(12): 3671–3679. doi: 10.11999/JEI200594 [15] 杨依忠, 汪鹏飞, 胡雄楼, 等. 基于鲁棒主成分分析的运动目标检测优化算法[J]. 电子与信息学报, 2018, 40(6): 1309–1315. doi: 10.11999/JEIT170789YANG Yizhong, WANG Pengfei, HU Xionglou, et al. Moving object detection optimization algorithm based on robust principal component analysis[J]. Journal of Electronics &Information Technology, 2018, 40(6): 1309–1315. doi: 10.11999/JEIT170789 [16] CHIPMAN R A, LAM W S T, and YOUNG G. Polarized Light and Optical Systems[M]. New York: CRC Press, 2018: 66–68. -

下载:

下载:

下载:

下载: